Production process for relay fermentation of novel plant growth promoting rhizobacteria type bio-organic fertilizer

A technology of bio-organic fertilizer and rhizosphere growth-promoting bacteria, which is applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems of influence, unstable product quality and application effect, and lack of research on enhancement technology, so as to improve soil quality, Enhance the survival and functional activity, and facilitate the effect of agricultural extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

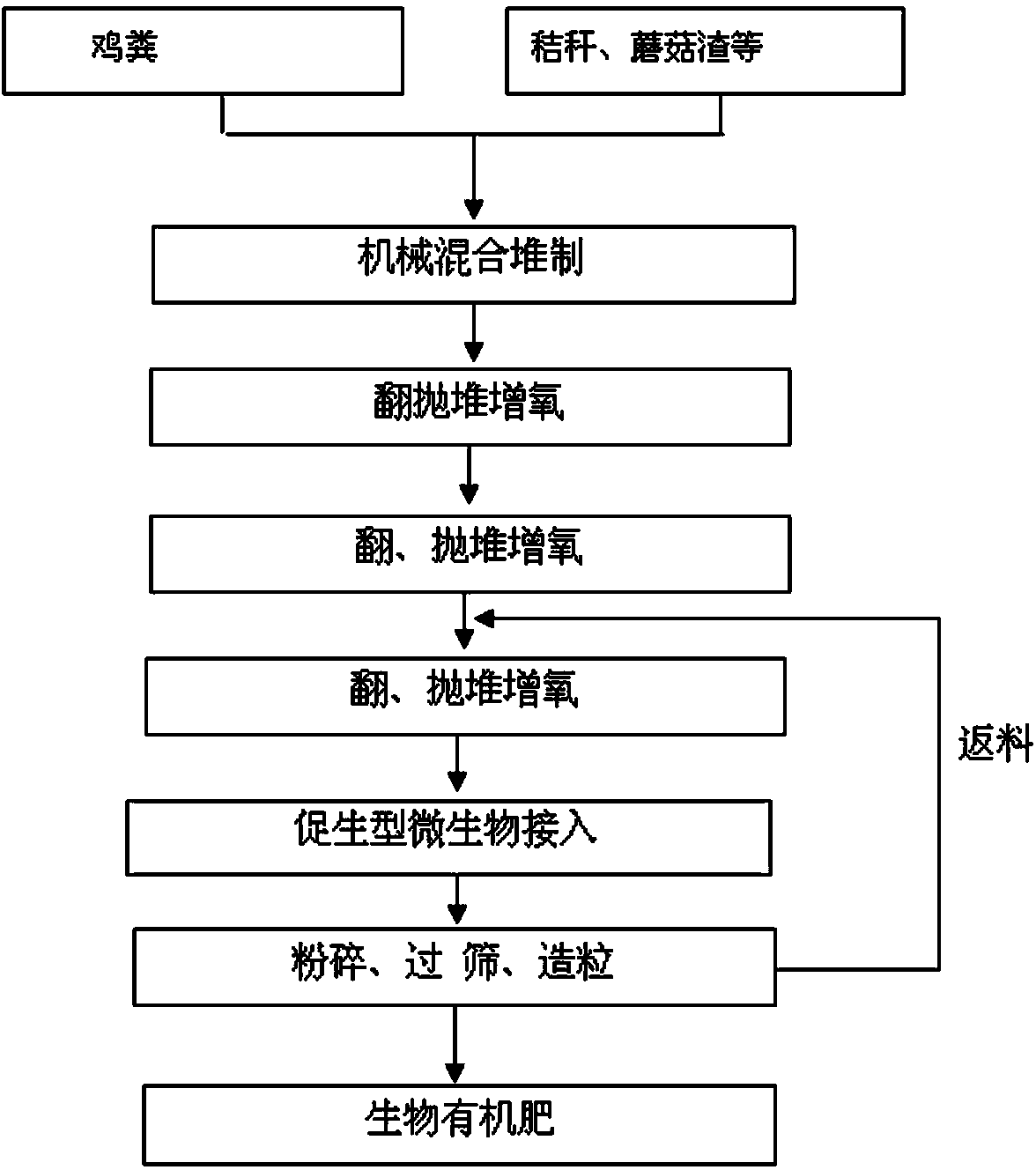

[0024] 1. The fresh chicken manure, straw, bone meal, mushroom residue and decomposing agent were mechanically mixed and fermented for 13 days according to the mass ratio of 35:34:20:6:5, and the fermentation temperature was controlled between 60°C;

[0025] 2. After three times of turning and throwing the heap to increase oxygen, in the cooling stage, inoculate the functional microorganisms when the temperature drops to 20°C, and ferment for 2 days until the number of cells is greater than 5 times the original inoculum, and then add the nutrient pack II, and continue Fermentation for 4 days, the fermentation temperature is controlled at 35 ℃;

[0026] 3. Finally, crush, sieve and granulate the materials that have been successfully inoculated and fermented to obtain a new type of bio-organic fertilizer of relay fermentation rhizosphere growth-promoting bacteria with a particle size of 30-60 mesh.

Embodiment 2

[0028] 1. The fresh chicken manure, straw, bone meal, mushroom residue and decomposing agent were mechanically mixed and fermented for 10 days according to the mass ratio of 52:15:23:5:5, and the fermentation temperature was controlled between 80 °C;

[0029] 2. After three times of turning and throwing the heap to increase oxygen, in the cooling stage, inoculate the functional microorganisms when the temperature drops to 20°C, and ferment for 2 days until the number of cells is greater than 5 times the original inoculum, and then add the nutrient pack II, and continue Fermentation for 3 days, the fermentation temperature is controlled at 50 ℃;

[0030] 3. Finally, crush, sieve and granulate the materials that have been successfully inoculated and fermented to obtain a new type of bio-organic fertilizer of relay fermentation rhizosphere growth-promoting bacteria with a particle size of 30-60 mesh.

Embodiment 3

[0032] 1. The fresh chicken manure, straw, bone meal, mushroom residue and decomposing agent were mechanically mixed and fermented for 14 days according to the mass ratio of 40:25:20:5:10, and the fermentation temperature was controlled between 70°C;

[0033] 2. After three times of turning and throwing the heap to increase oxygen, in the cooling stage, inoculate the functional microorganisms when the temperature drops to 20 ° C, and ferment for 3 days until the number of cells is greater than 5 times the original inoculum, and then add the nutritional package II, and continue Fermentation for 3 days, the fermentation temperature is controlled at 40 ℃;

[0034] 3. Finally, crush, sieve and granulate the materials that have been successfully inoculated and fermented to obtain a new type of bio-organic fertilizer of relay fermentation rhizosphere growth-promoting bacteria with a particle size of 30-60 mesh.

[0035] In this embodiment, the functional microorganisms may be plant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com