Infrared brown camouflage paint and preparation method and application thereof

A technology of stealth paint and brown pigment, which is applied in the direction of epoxy resin paint, polyurea/polyurethane paint, coating, etc., can solve the problems of lower emissivity and high cost, and achieve the effect of low emissivity and good stealth compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation infrared brown stealth paint T1

[0042] At 25°C, weigh 5 parts of iron oxide brown pigment, 10 parts of titanium chrome brown pigment, 5 parts of bismuth yellow pigment, 5 parts of carboxymethyl cellulose, 5 parts of flake aluminum powder (particle size is 15 μm), polyacrylate (Molecular weight: 75000) 25 parts, deionized water 45 parts, after mixing, ultrasonically disperse for 0.5 hours, and stir at a speed of 500 rpm for 6 hours to obtain infrared stealth brown paint T1.

[0043] The IR-2 dual-band emissivity measuring instrument developed by the Shanghai Institute of Physics and Technology, Chinese Academy of Sciences was used to measure the infrared stealth brown paint T1 prepared in this example, and its emissivity in the 8-14 μm band was measured to be 0.79.

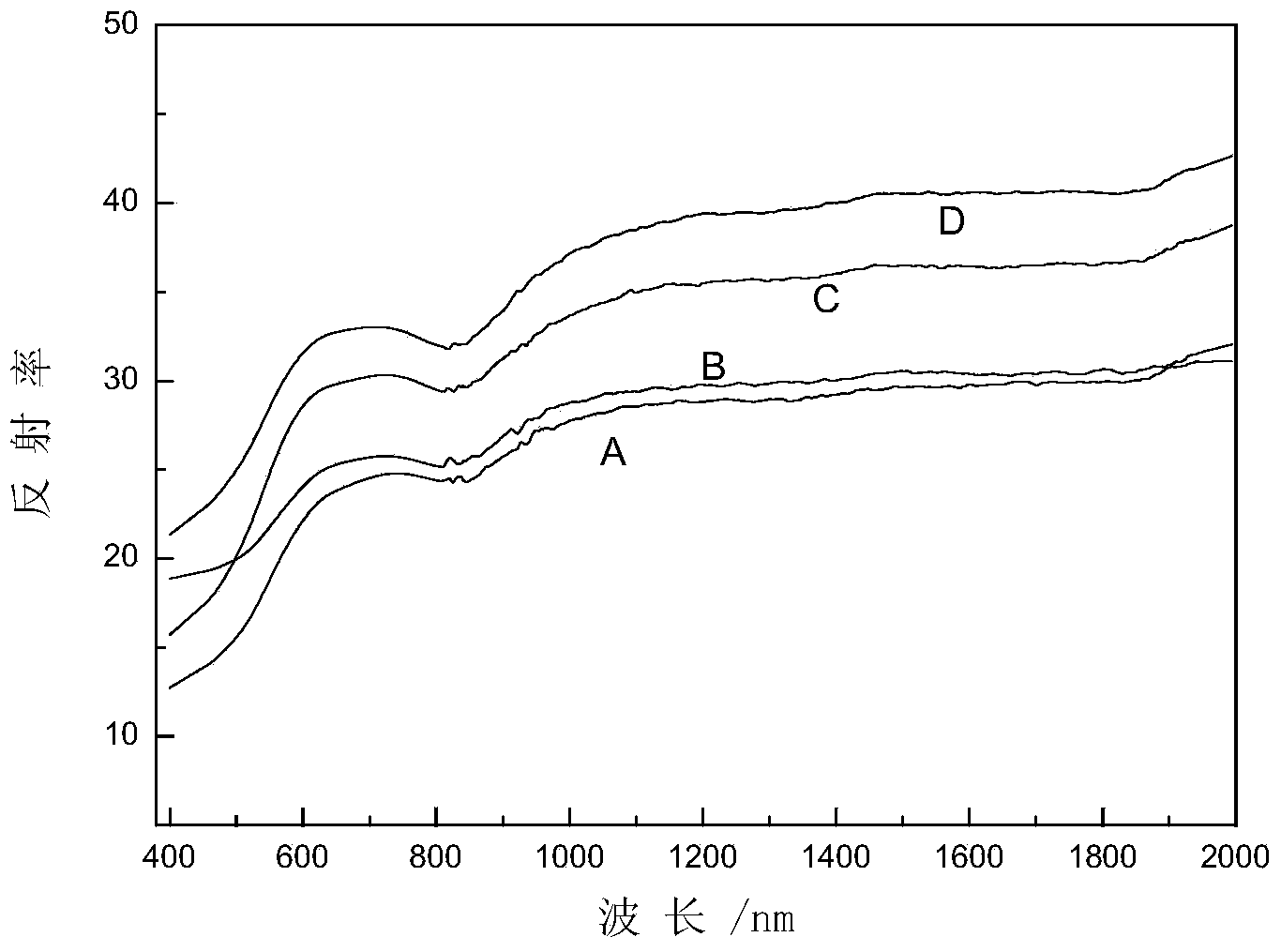

[0044] The visible light-near-infrared reflectivity test result of the polyester / cotton blended fabric (coating thickness is 30 μ m) coated with the brown infrared stealth paint T...

Embodiment 2

[0046] Embodiment 2, preparation brown stealth paint T2

[0047]At 25°C, weigh 10 parts of zinc iron chromium brown pigment, 5 parts of nickel titanium yellow pigment, 5 parts of chrome yellow pigment, 1 part of carboxymethyl cellulose, 1 part of hydroxyethyl cellulose, flake aluminum powder (granular Diameter 28μm) 10 parts, polyacrylate (molecular weight 75000) 20 parts, ethylene-vinyl acetate resin (molecular weight 83000) 5 parts, deionized water 43 parts, after mixing, ultrasonic dispersion 0.6 hours, at room temperature and pressure Stir at a speed of 1000 rpm for 5 hours to obtain the infrared stealth brown paint T2, and use the IR-2 dual-band emissivity measuring instrument developed by the Shanghai Institute of Physics and Technology, Chinese Academy of Sciences to measure its emissivity in the 8-14 μm band 0.75.

[0048] The visible light-near-infrared reflectivity test result of the polyester / cotton blended fabric (coating thickness is 30 μ m) coated with the brown...

Embodiment 3

[0050] Embodiment 3, preparation brown stealth paint T3

[0051] At 25°C, weigh 5 parts of titanium chrome brown pigment, 5 parts of iron oxide yellow pigment, 10 parts of bismuth yellow pigment, 2 parts of polyacrylamide (molecular weight 90000), 1 part of casein, flake aluminum powder (particle size 36 μm ) 15 parts, 27 parts of polyurethane (molecular weight is 70000), 35 parts of deionized water, after mixing, ultrasonically disperse for 0.8 hours, and stir for 4 hours at a speed of 1500 rpm under normal temperature and pressure to obtain the infrared stealth brown coating T3 , using the IR-2 dual-band emissivity measuring instrument developed by the Shanghai Institute of Physics and Technology, Chinese Academy of Sciences, the emissivity in the 8-14μm band was measured to be 0.72.

[0052] The visible light-near-infrared reflectivity test result of the polyester / cotton blended fabric (coating thickness is 30 μ m) coated with the infrared stealth brown paint prepared by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com