Insulating heat-conducting metal-to-metal adhesive and manufacturing method thereof

A technology of heat-conducting metal and manufacturing method, applied in the field of heat-conducting adhesive, can solve the problem of unrealizable heat dissipation, and achieve the effects of avoiding leakage, high thermal conductivity, and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

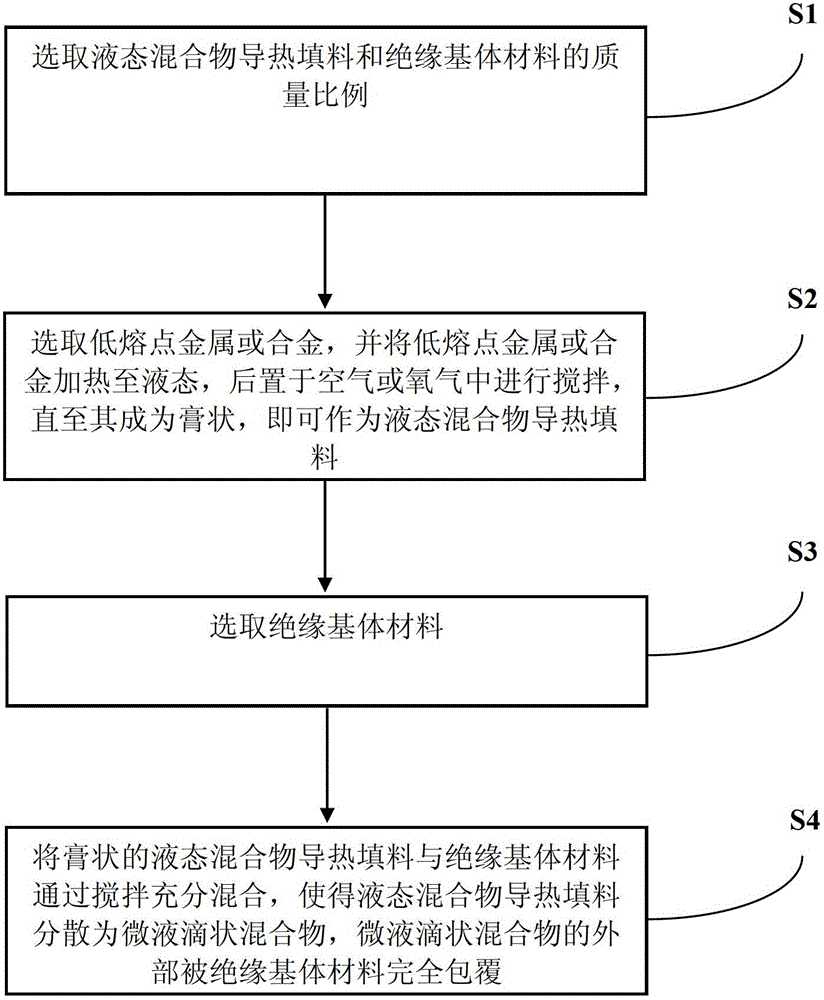

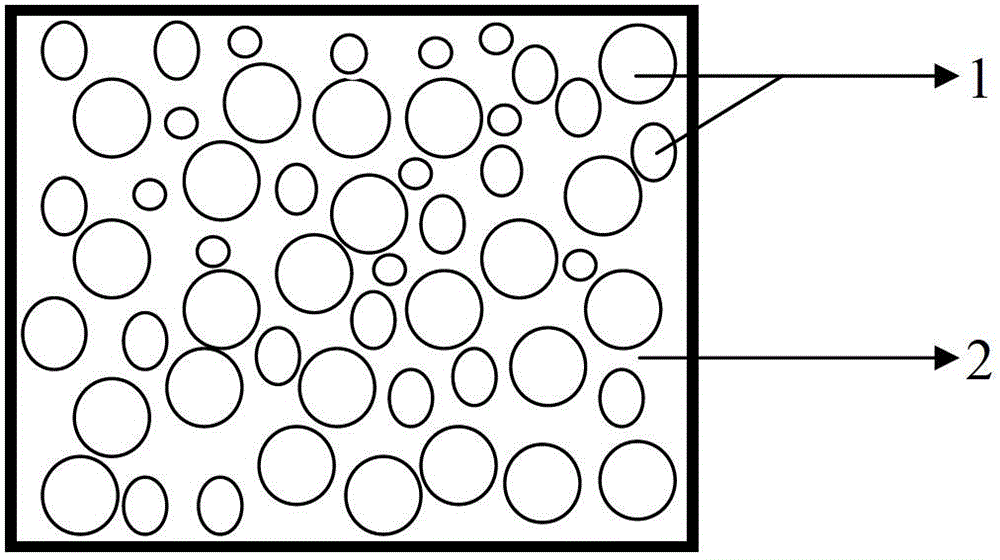

[0056] Such as figure 1 Shown, a kind of manufacturing flowchart of insulating heat-conducting metal adhesive, described method comprises the steps:

[0057] Step S1, selecting the mass ratio of the thermally conductive filler of the liquid mixture and the insulating base material 2 to be 20:1;

[0058] Step S2, weighing 40g of low-melting-point gallium-indium alloy Ga: 24.5In, whose melting point is 15.7°C. At room temperature, the alloy is in a liquid state, and the gallium-indium alloy is heated in an air environment at a heating temperature of 50°C C; Stir the mixture of gallium-indium alloy and gallium-indium alloy oxide at a stirring rate of 500rpm for 0.1 to 10 hours until the mixture changes from liquid to paste, which can be used as a liquid mixture heat conducting filler ;

[0059] In step S3, the insulating base material 2 selects a type of HCY5299 low-viscosity flame-retardant two-component silicone heat-conducting potting glue, weighs 2g of silicone heat-conduct...

Embodiment 2

[0062] According to the preparation method of example 1, just change air into pure oxygen environment.

Embodiment 3

[0064] According to the preparation method of Example 1, only the insulating matrix material 2 is replaced by epoxy resin from silicone heat-conducting potting compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com