Complex bacterial preparation for degrading non-wood-fiber lignin and preparation method thereof

A non-wood fiber and composite bacterial agent technology, which is applied in the field of lignin rapid degradation bacterial agent and lignin composite bacterial agent, can solve the problems of lignin refractory degradation, low efficiency, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

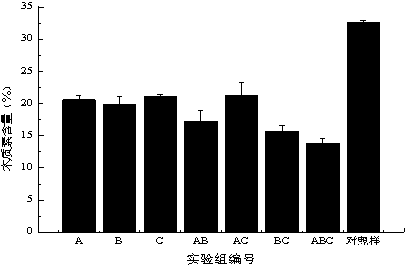

[0021] Aspergillus fumigatus is numbered A, Penicillium chrysogenum is numbered B, and Penicillium vulgaris is numbered C. Configure 300mL PDA culture based on a 500mL triangular flask, use the inoculation loop to pick out 3-5 rings of each of the three strains of A, B, and C, and culture single bacteria. Inoculate in liquid PDA medium at a ratio of 1:1 and 1:1:1, culture on a shaker at 30°C and 170rpm, and after three days of cultivation, put 10g of sterilized reed into it, take samples every two days, and measure Lignin content, such as figure 1 shown. from figure 1 It can be seen that B bacteria has the best degradation effect of a single species of bacteria, and the degradation rate is 38.8%. The best degradation effect of the two bacteria is the combination of BC, with a degradation rate of 43.02%. Well, the degradation rate reached 57.59%, and the degradation of reed lignin by the mixture of three bacteria was significantly better than that by single bacteria or by th...

Embodiment 2

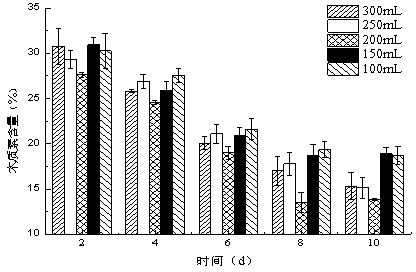

[0023] Aspergillus fumigatus is numbered A, Penicillium chrysogenum is numbered B, and Penicillium vulgaris is numbered C. Configure 300mL PDA culture based on a 500mL triangular flask, use the inoculation loop to pick out 3-5 rings of each of the three strains of A, B, and C, and after three days of cultivation, according to (bacterial liquid volume ratio) A:B:C=1:1 Inoculate 10 mL in different amounts (100 mL, 150 mL, 200 mL, 250 mL, 300 mL) of liquid PDA medium at a ratio of 1:1, cultivate on a shaker at 30°C and 170 rpm, and after three days of cultivation, 10 g of sterilized reed Put it in, take a sample every two days, measure the lignin content, such as figure 2 shown. from figure 2 It can be seen that when the bacterial liquid is 200mL, the degradation effect is the best, and the degradation effect is the best on the tenth day, the lignin content is 13.55%, and the degradation rate is 58.41%.

Embodiment 3

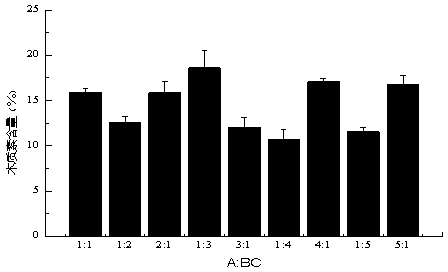

[0025] Aspergillus fumigatus is numbered A, Penicillium chrysogenum is numbered B, and Penicillium vulgaris is numbered C. Configure 200mL PDA culture based on a 500mL triangular flask, use the inoculation loop to pick out 3-5 rings of each of the three strains of A, B, and C, and after three days of cultivation, on the basis of a BC mixing ratio of 1:4 (bacteria liquid volume ratio) Above, inoculate with A in 200 mL liquid PDA medium according to different mixing ratios (bacteria liquid volume ratio: 1:1, 1:2, 1:3, 1:4, 1:5), at 30°C, 170rpm shaker cultivation, after cultivation for three days, put 10g sterilized reeds into it, take a sample every two days, measure the lignin content, such as image 3 shown. from image 3 It can be seen that on the basis of the BC bacteria mixing ratio of 1:4, the mixing ratio of the three ABC bacteria is optimized, and the volume ratio of the ABC mixed bacteria is A:B:C=1:4:16, and on the 8th day, the degradation The effect is the best, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com