Polishing rubber disc face shape detection device for large annular polishing machine

A detection device and polishing glue technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of increasing the risk of workpiece handling, inconvenient handling by workers, large workpiece size, etc., to avoid the influence of external stray light, eliminate Safety and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but should not limit protection scope of the present invention with this.

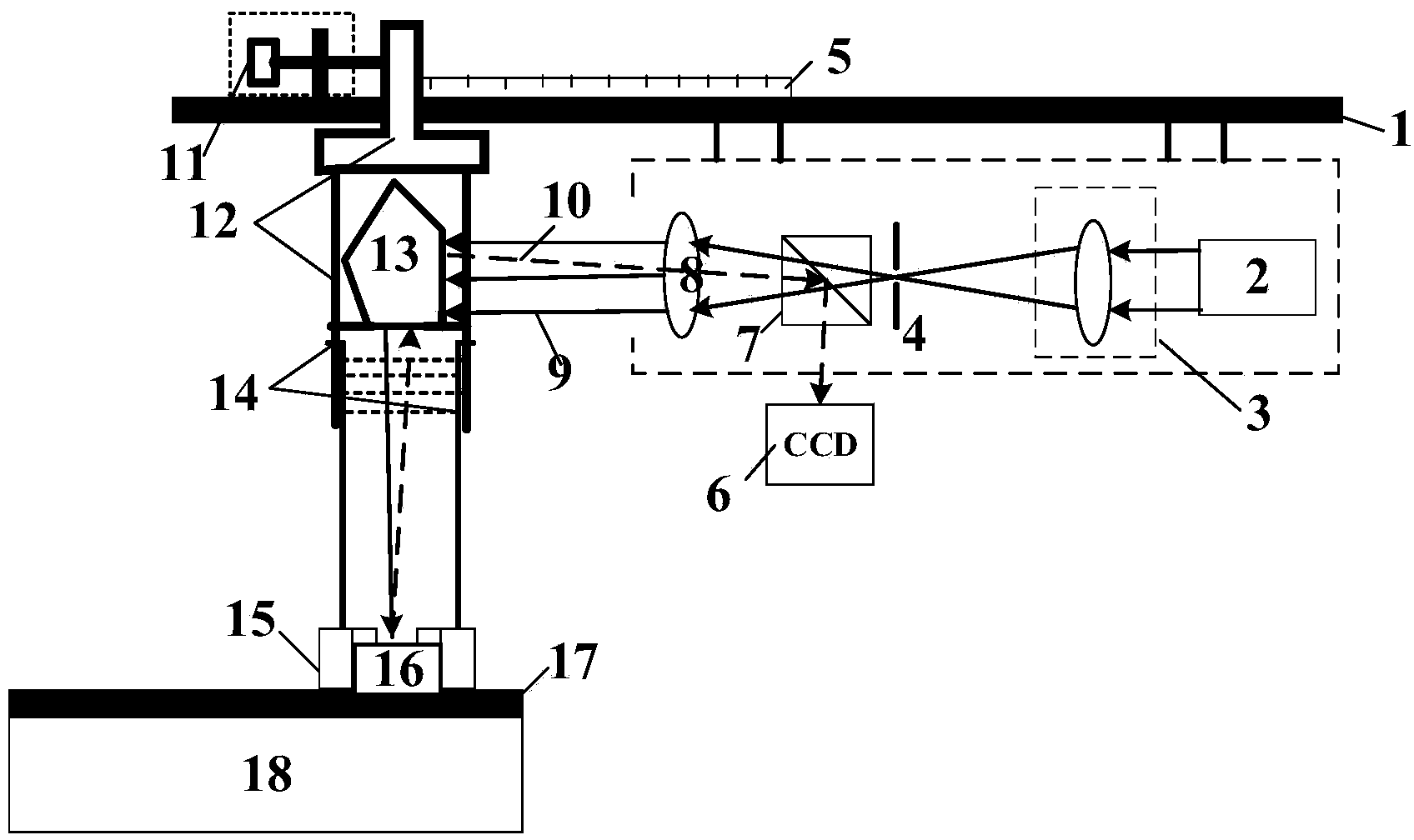

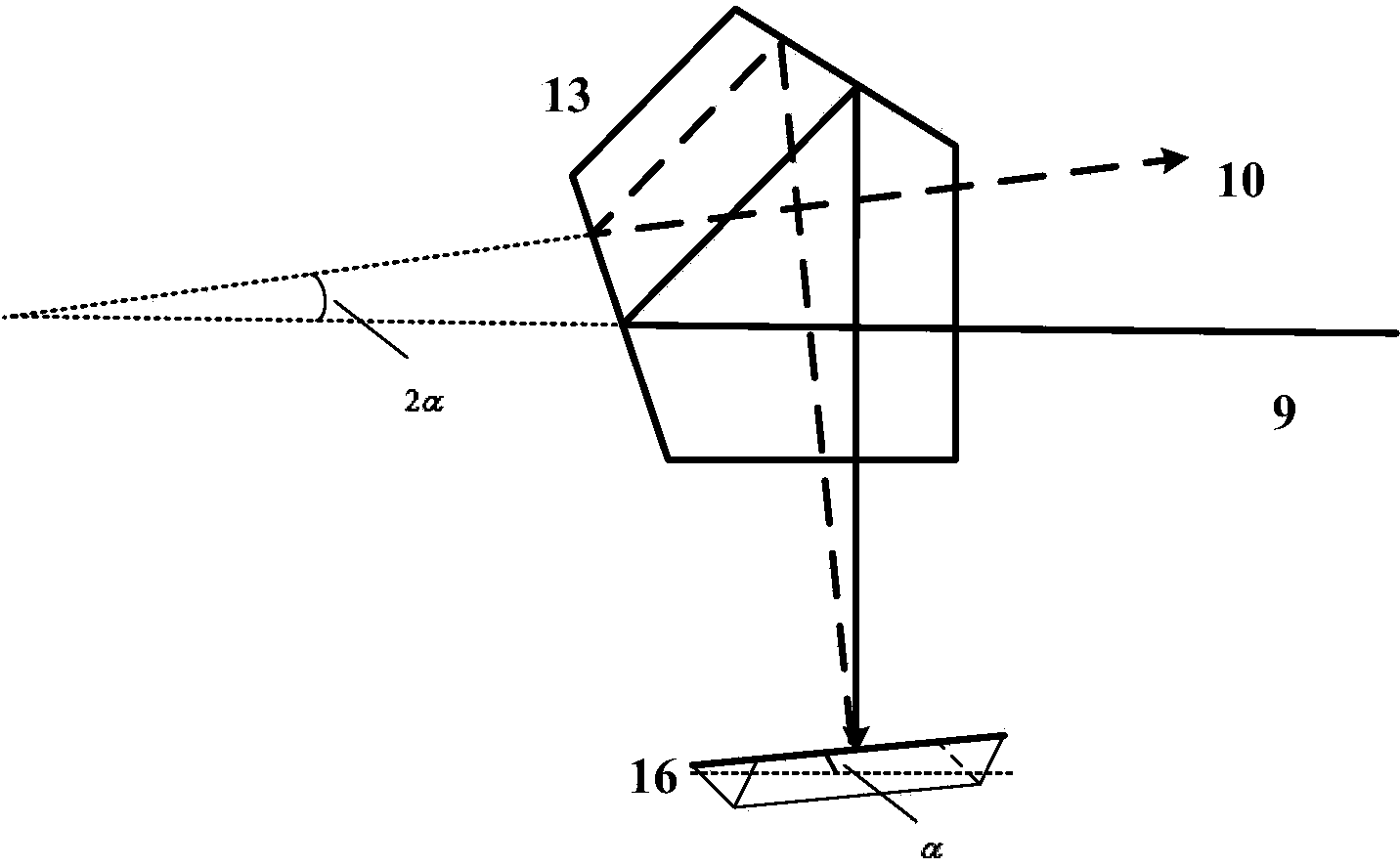

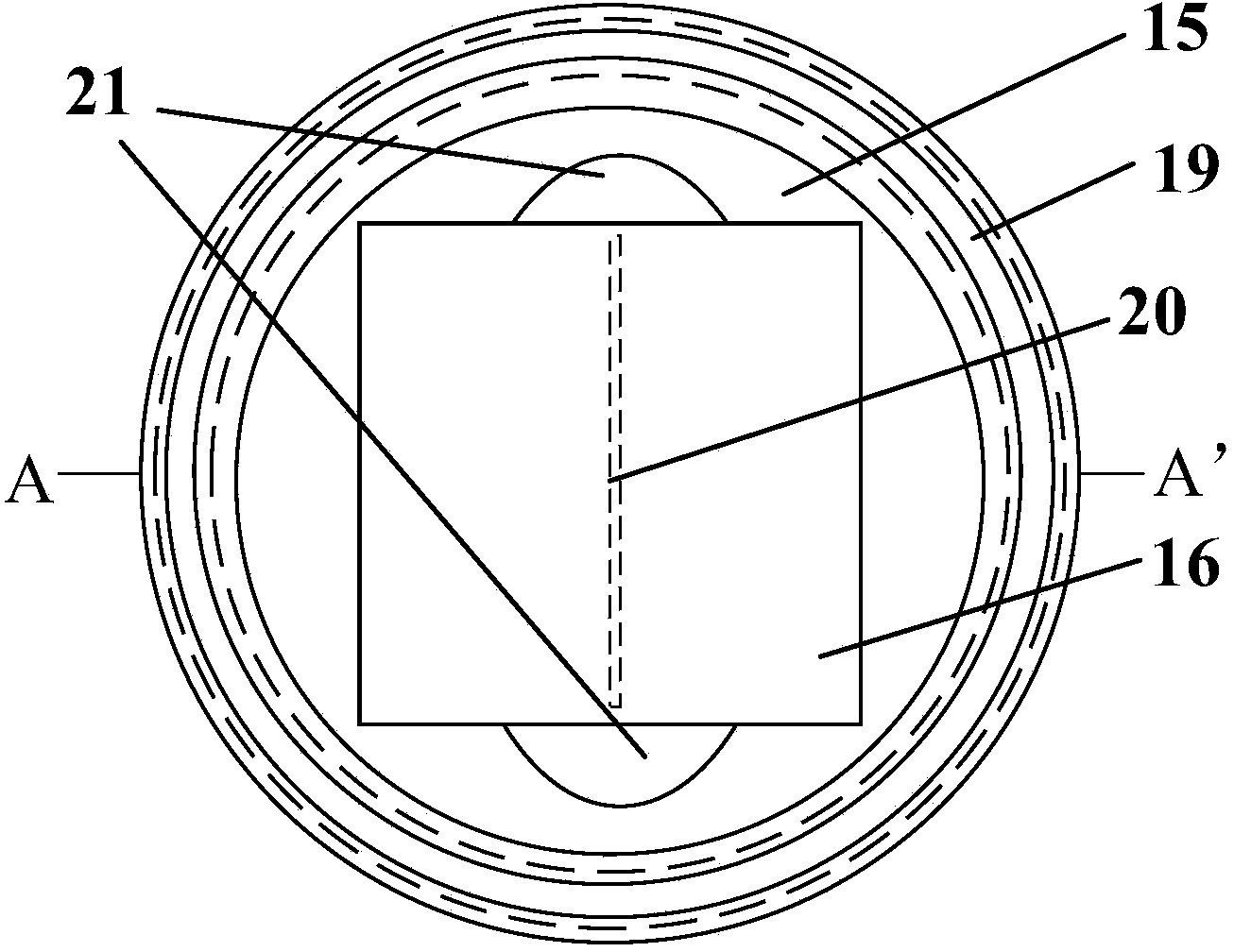

[0023] refer to figure 1 , figure 1 It is a structural schematic diagram of the best embodiment of the surface shape detection device for large-scale ring polishing machine polishing rubber discs of the present invention. As can be seen from the figure, the surface shape detection device for polishing rubber discs of large-scale ring polishing machines of the present invention includes a light belt fixed on the polishing machine frame. A straight guide rail 1 with a ruler 5, a displacement adjustment device 11 fixed on the straight guide rail 1 and a mobile platform 12 driven to move along the straight guide rail 1, a laser device 2, a lens group 3, and a slit light packaged in sequence Diaphragm 4, dichroic prism 7 and collimating prism 8 are fixedly suspended below the described straight guide rail, the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com