Vacuum leak detection method and vacuum leak detection system for containers

A leak detection and vacuum technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc., can solve problems such as misjudgment, achieve high detection accuracy, avoid false detection, and mechanism structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

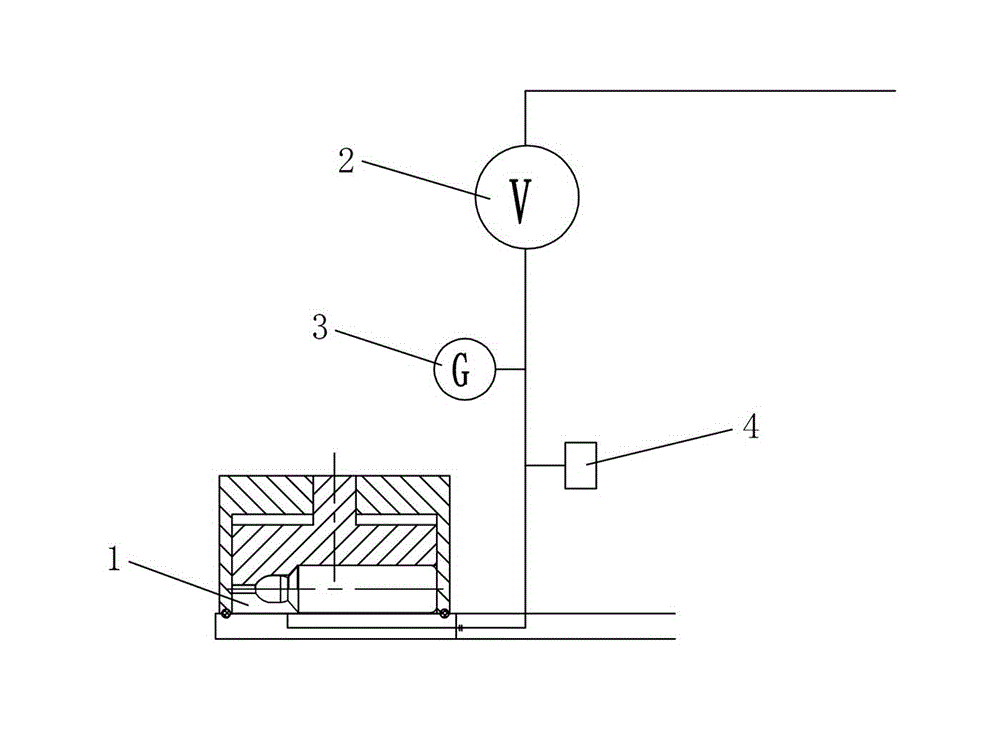

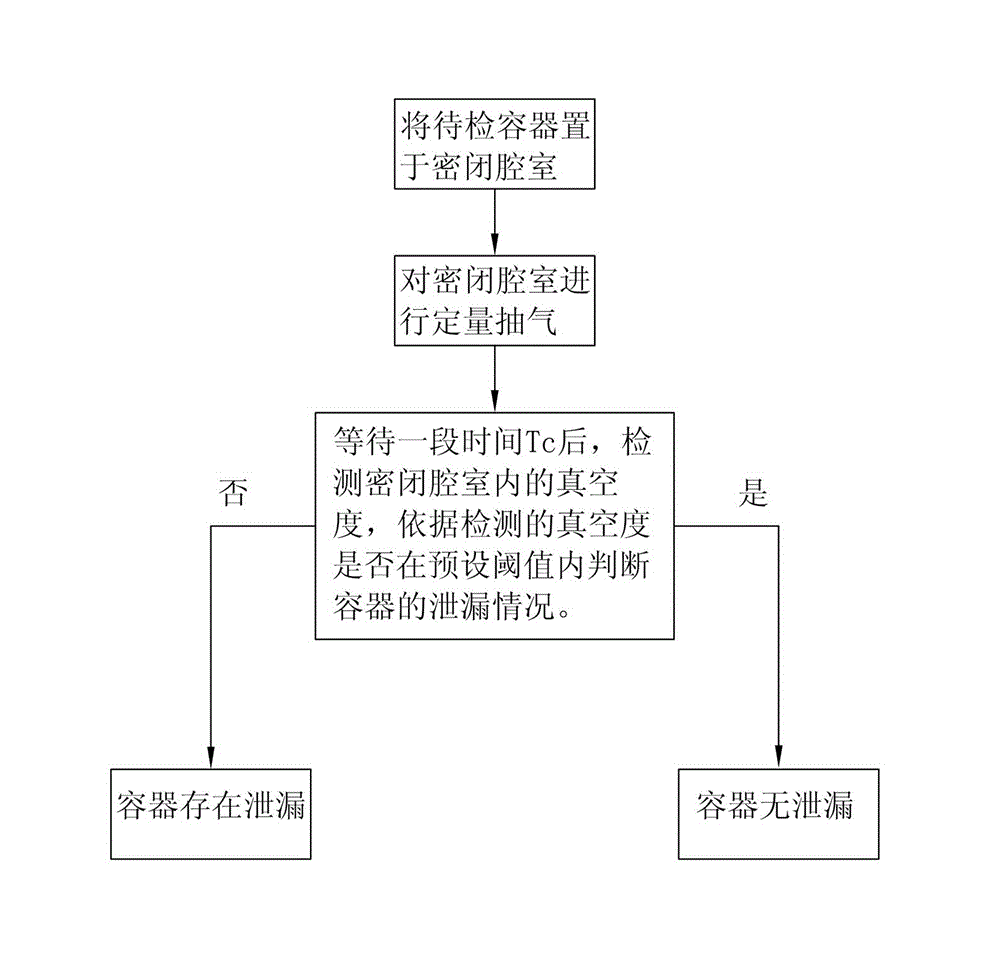

[0041] Such as Figure 5 As shown, the vacuum leak detection system of this embodiment includes an air pump 2, an airtight chamber 1 for accommodating the object to be inspected (plastic ampoule 10), and an air suction channel 9 connecting the air pump 2 and the airtight chamber 1. The channel 9 is connected with a detection device for detecting the degree of vacuum, and a quantitative control component for controlling the pumping volume is also provided on the pumping channel 9 , and the quantitative control component adopts a flow meter 5 . When working, the air pump 2 pumps air to the airtight chamber 1, and the amount of air pumping is controlled by the flow meter 5; the detection device detects the degree of vacuum in the airtight chamber 1.

[0042] In this embodiment, the detection device is a vacuum pressure gauge 3 and a pressure sensor 4, wherein the pressure sensor 4 can detect the degree of vacuum in the airtight chamber 1, and feed back the signal to the control mec...

Embodiment 2

[0047] Such as Image 6 As shown, the vacuum leak detection system of this embodiment is basically the same as that of Embodiment 1. The difference is that this embodiment is also provided with a control valve 11 on the air extraction channel 9, and the control valve 11 can control the flow of the air extraction channel 9. Off, it can use a solenoid valve. When the control valve 11 is connected to the air extraction channel 9, the airtight chamber 1 can be evacuated, and when the control valve 11 is disconnected from the air extraction channel 9, the airtight chamber 1 after the air extraction can be kept under pressure. , and then control the control valve 11 to communicate with the air extraction channel 9 to perform exhaust.

Embodiment 3

[0049] Such as Figure 7 As shown, this embodiment is basically the same as Embodiment 2, the difference is that the vacuum leak detection system of this embodiment is provided with four airtight chambers 1, and each airtight chamber 1 is connected to an air extraction channel 9, all The air extraction channel 9 is connected with the air pump 2 through a main channel 13, that is, the main channel 13 communicates with the inlet port (air inlet) of the air pump 2, and one end of each air extraction channel 9 communicates with the airtight chamber 1, and the other end communicates with the airtight chamber 1. The main channel 13 communicates. A vacuum pressure gauge 3, a pressure sensor 4 and a control valve 11 are provided on each air extraction channel 9, and the air extraction pump 2 simultaneously evacuates the four airtight chambers 1 during use. On each pumping channel 9 , the vacuum pressure gauge 3 and the pressure sensor 4 detect the vacuum degree of the corresponding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com