An integrated pulsed ultrasound-acoustic emission transducer for inspection of composite materials

A composite material and pulsed ultrasonic technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of complex detection signal laws, poor time-domain pulse characteristics of transducers, and decreased defect detection ability, and achieves improved sensitivity. and defect detection ability, improve detection sensitivity and resolution, improve the effect of time domain pulse characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

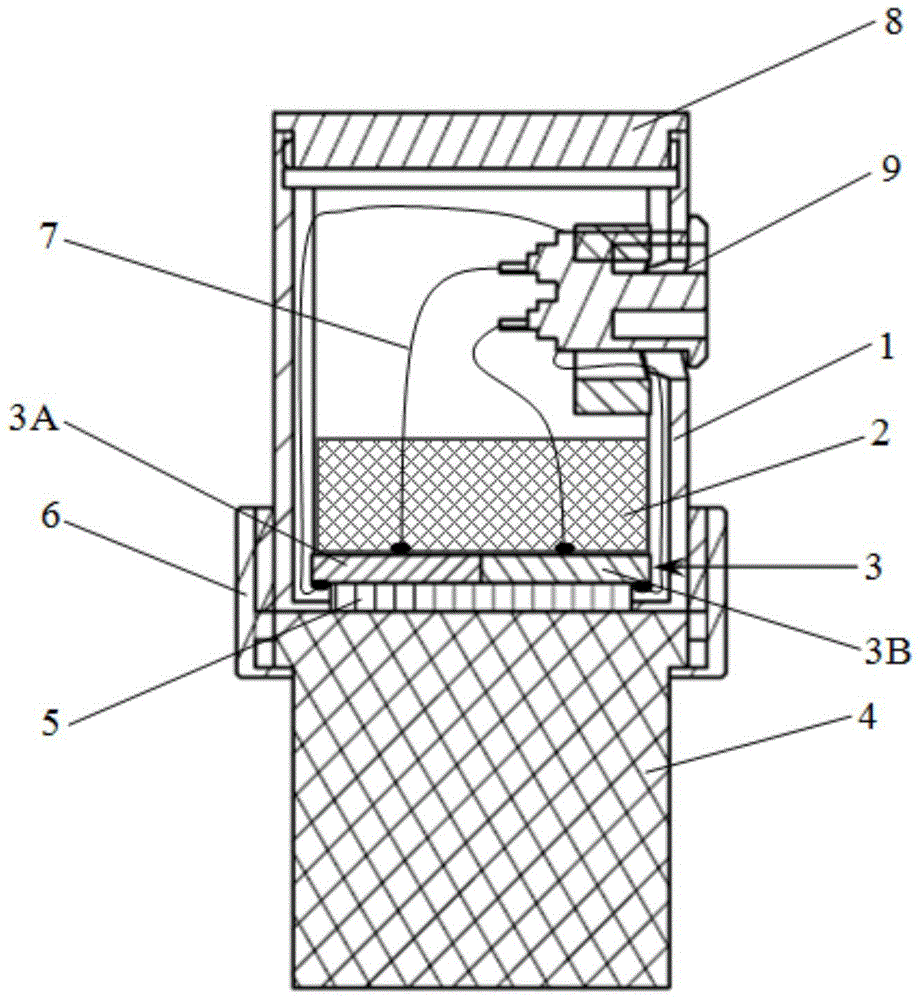

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

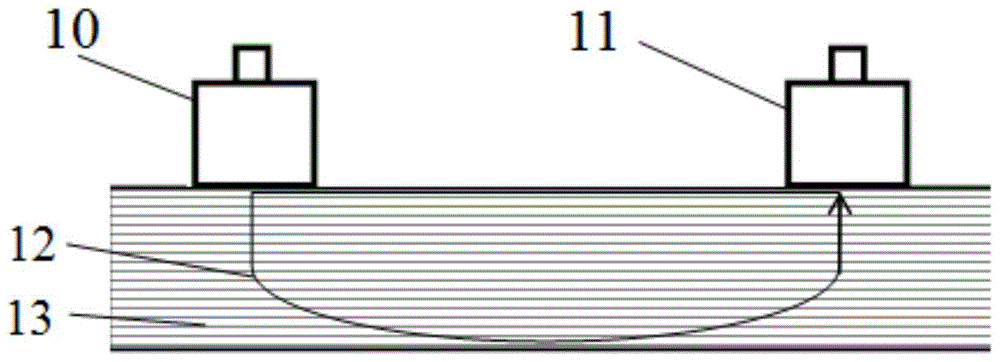

[0026] An integrated pulsed ultrasonic-acoustic emission transducer for detecting composite materials, including a transducer housing 1, a damping back block 2, a piezoelectric sensing element 3, a delay block 4, a matching layer 5, and a lock Tight ring 6, electrode 7, cover 8 and connecting seat 9, see figure 2 shown.

[0027] The damping back block 2 is formed by mixing epoxy resin and tungsten powder, and the lower end surface of the damping back block 2 is bonded and fixed to the upper surface of the piezoelectric sensing element 3;

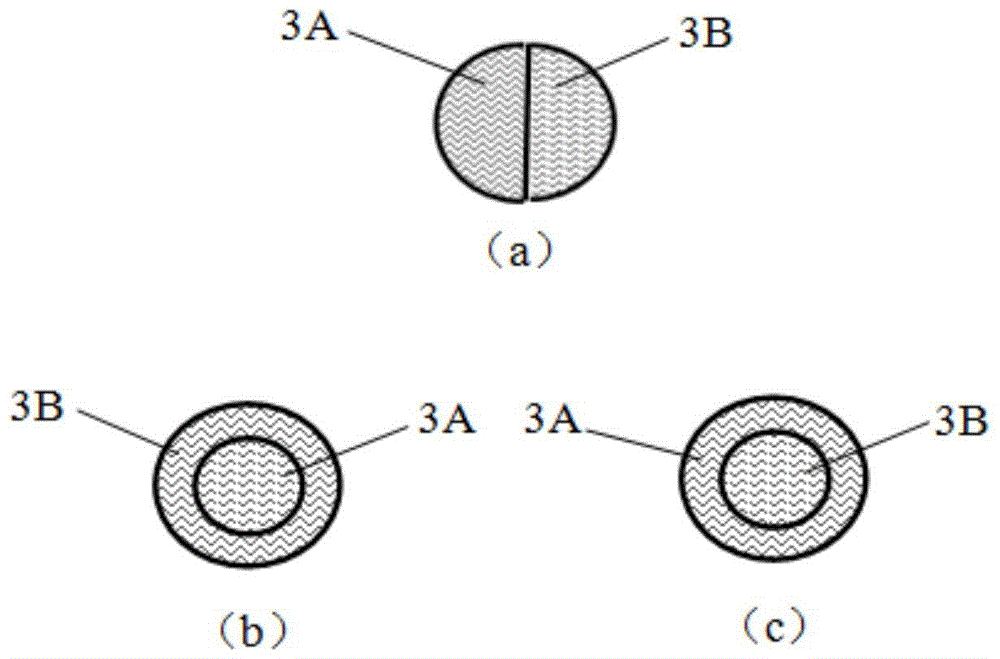

[0028] The piezoelectric sensing element 3 is processed by a pair of piezoelectric crystals 3A and 3B with matching frequency characteristics. It adopts two matching modes of frequency characteristics, symmetrical or asymmetrical. The frequency range is 1MHz-10MHz, and the geometric layout is 3 different layouts. One: 1) piezoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com