Combined cutter and separable cutting method of ceramic substrate LED

A ceramic substrate, combined technology, used in manufacturing tools, fine working devices, stone processing equipment, etc., can solve problems such as rapid wear, large cutting heat, and pulling on chip gold wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

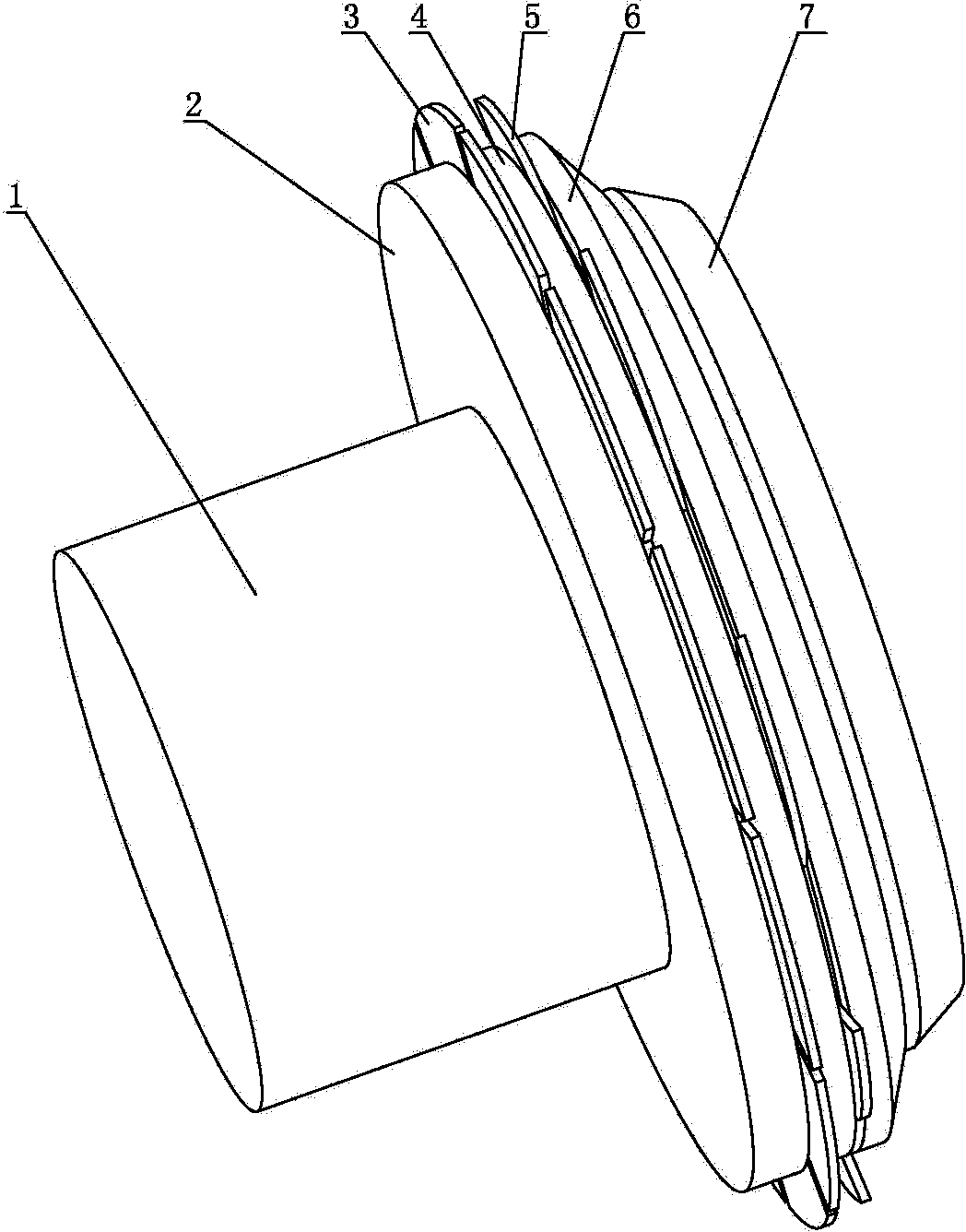

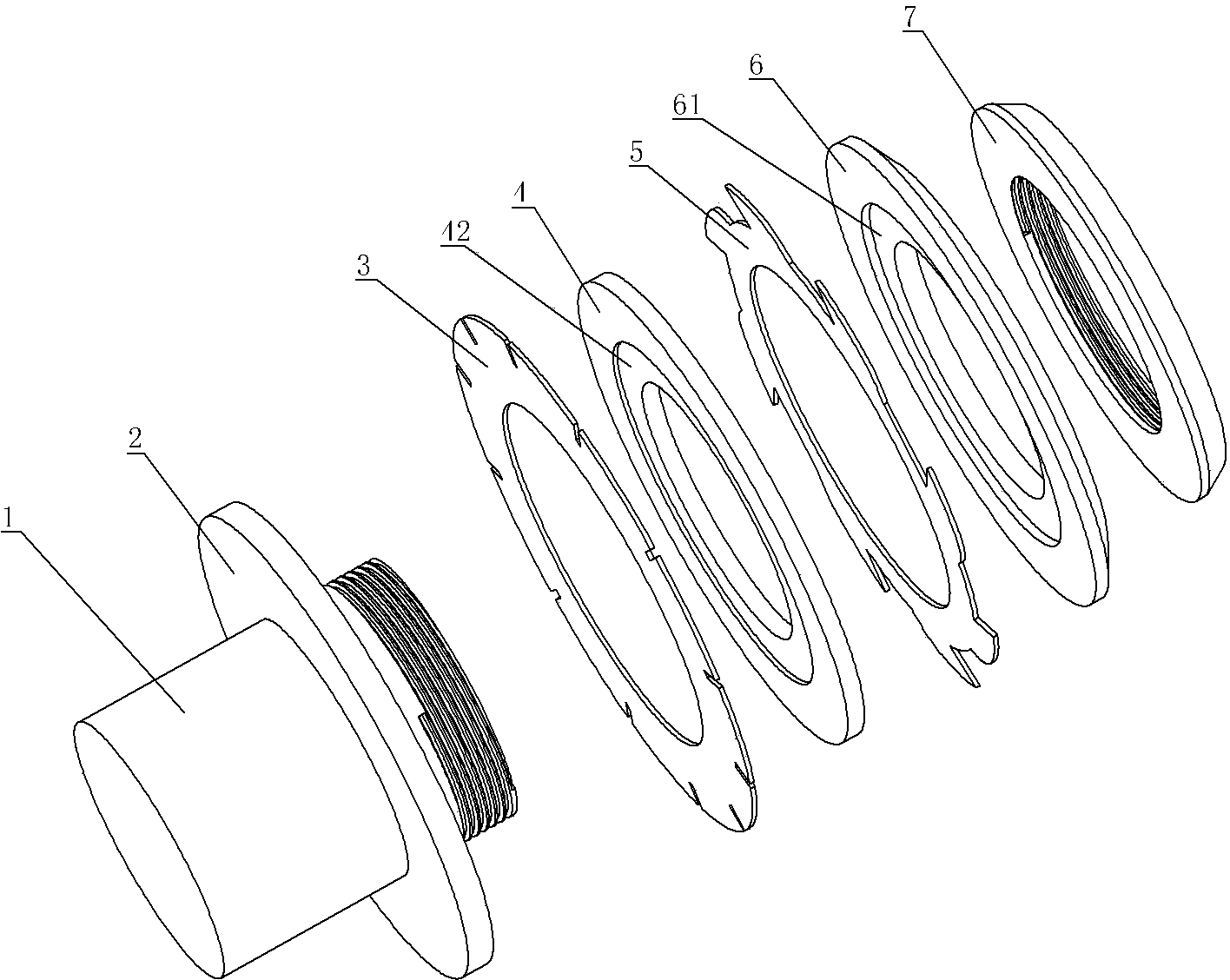

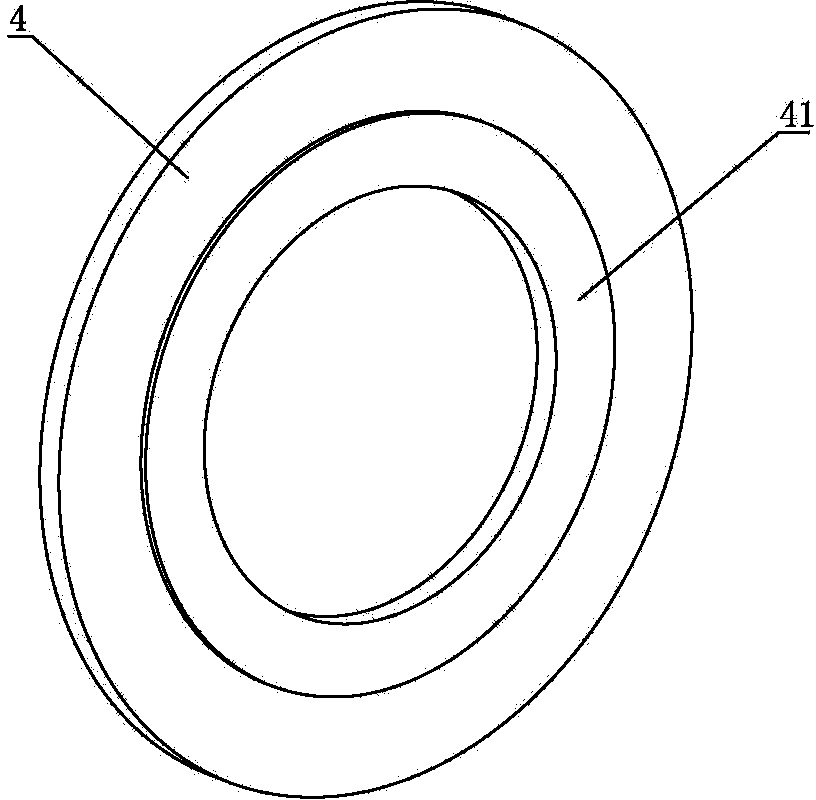

[0035] Such as Figure 1 to Figure 2As shown, the combined tool includes a main shaft 1, a main shaft flange 2, a grinding wheel 3, a flange gasket 4, a disc milling blade 5, a gasket 6 and a locking device, and the main shaft flange 2 is fixed on the main shaft 1, generally the two are integrated, the grinding wheel 3, the flange gasket 4, the disc milling blade 5, and the gasket 6 are set on the main shaft 1 from the back to the front, and the flange gasket 4 is used to install the grinding wheel 2. The locking device is a lock nut, and the lock nut 7 is connected to one end of the main shaft 1 through threads, and is used to lock and fix the grinding wheel 3, the flange gasket 4, the disc milling blade 5, and the gasket 6, among which , the thickness of the flange gasket 4 is flexibly selected according to the size of the LED, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com