Method for producing edible salt from sea water through industrial process and processing device of edible salt

A technology for processing equipment and edible salt, which is applied in the field of industrial seawater production of edible salt technology and processing equipment, which can solve the problems of large land and human resources, many impurities, and low salt purity, and achieve high automation, low investment, and saving land effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

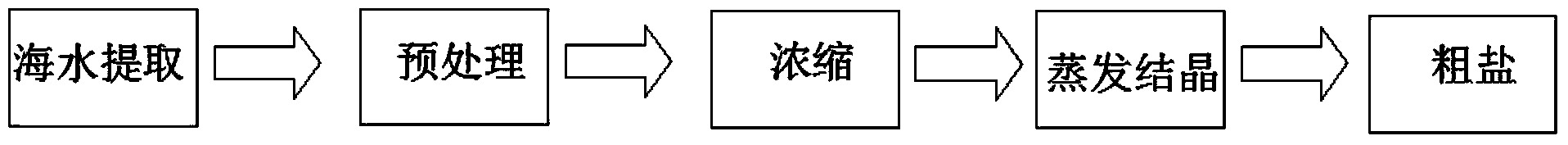

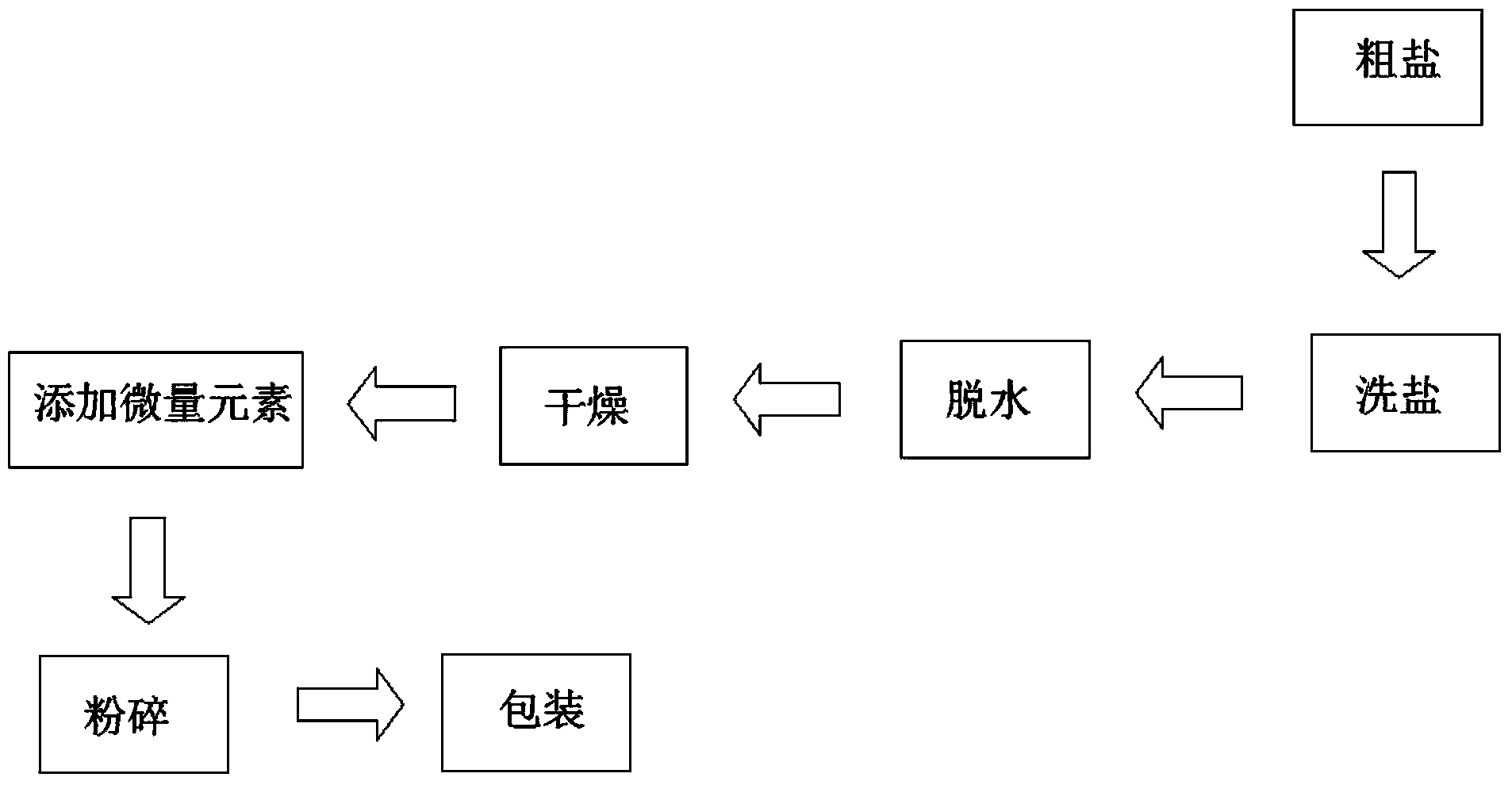

[0039] like figure 1 As shown, the industrial method seawater production process of edible salt, the process includes seawater extraction step, precipitation step, filtration step, concentration step, preheating step and evaporation crystallization step.

[0040] Seawater extraction: The water pump is used to send the seawater through the pipeline to the sedimentation tank for sedimentation, so that the salt making process is not affected by the tide, and the sediment and other impurities in the seawater are clarified in the sedimentation tank.

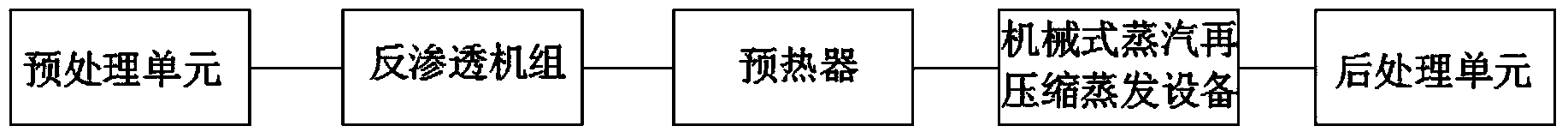

[0041] Pretreatment: filter the seawater precipitated in the sedimentation tank with a filter device to remove suspended solids and microorganisms in the seawater, so that the seawater can reach the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com