Method for changing cement concrete pavement into pervious concrete pavement

A technology of permeable concrete and cement concrete, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of blocking groundwater replenishment, affecting urban sanitation, aggravating the urban heat island effect, etc., and achieving the effect of strengthening the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples. However, the scope of application of the present invention is not limited to the following examples.

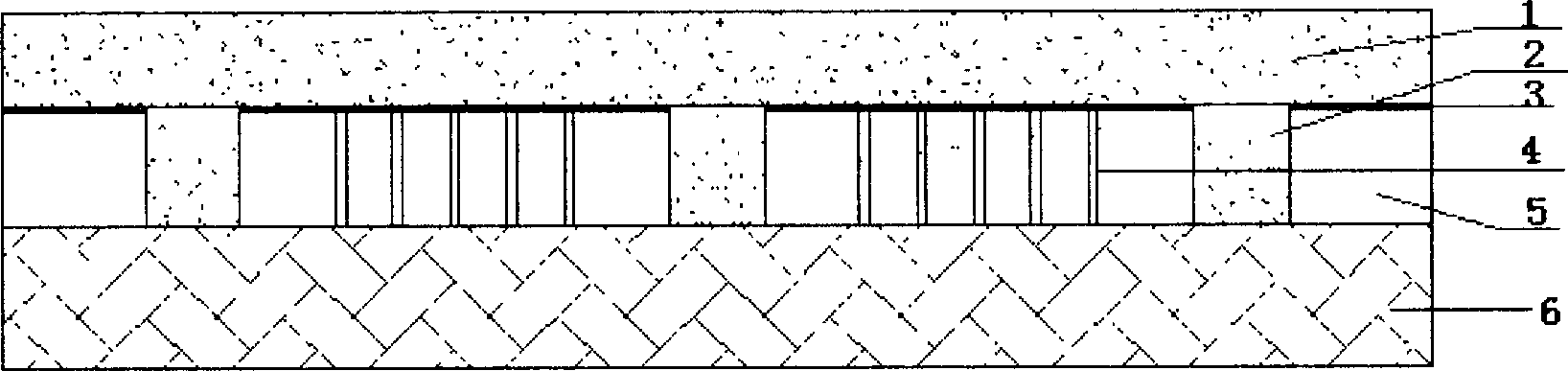

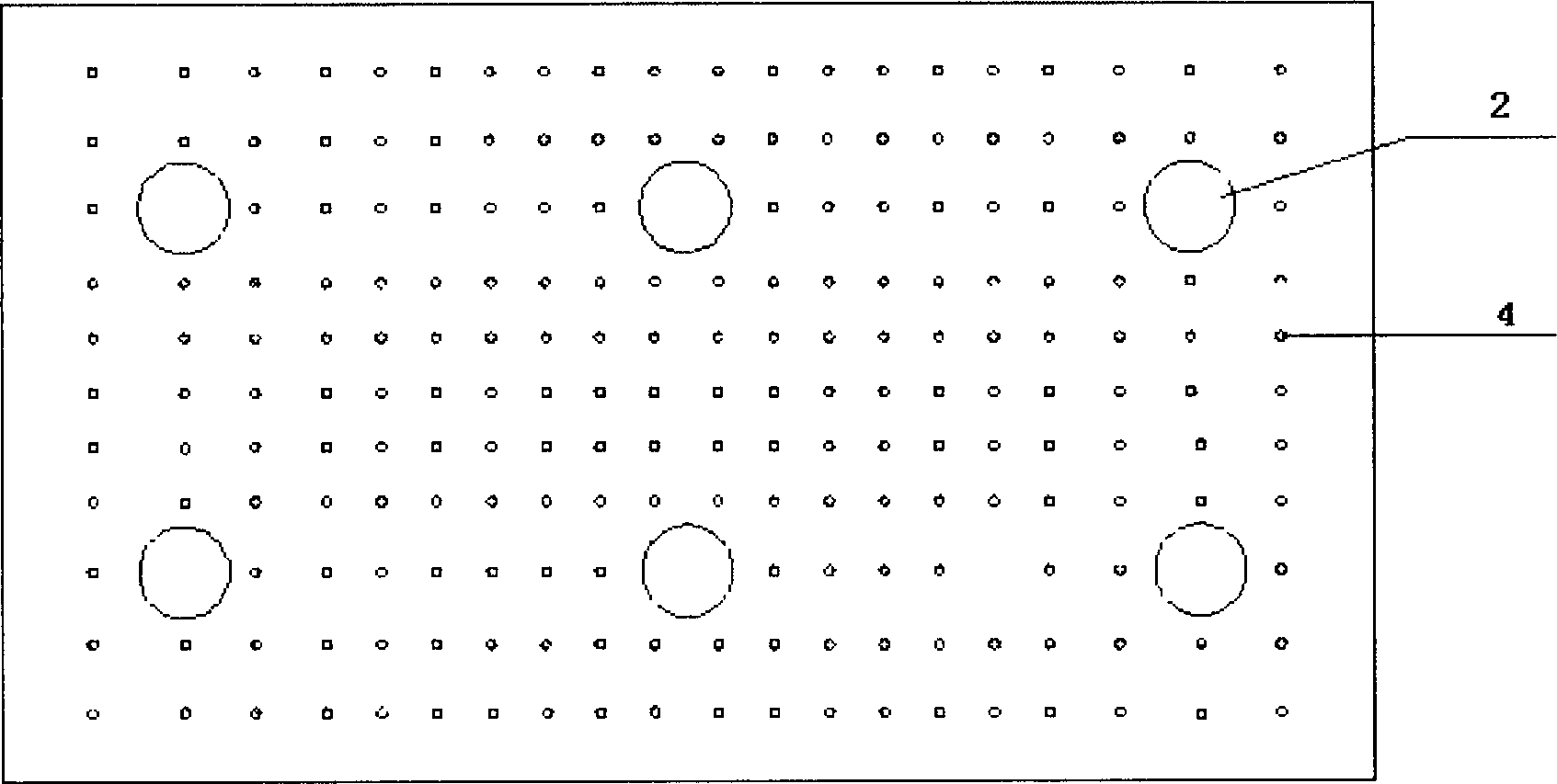

[0030] Such as figure 1 with figure 2 , a method for changing a cement concrete pavement into a permeable concrete pavement, is characterized in that the method is carried out sequentially according to the following steps:

[0031] A. Determine the porosity P of the permeable concrete according to the actual local conditions, and prepare the corresponding permeable concrete;

[0032] B. Drill holes evenly on the cement concrete pavement, and ensure that each hole runs through the cement concrete pavement layer 5 to the subgrade 6. The holes are composed of uniformly distributed large holes 2 and small holes 4 evenly distributed around the large holes 2 , and the number of large holes 2 is far less than the number of small holes 4, the ratio of the sum of the orifice area to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com