Revolution machine as well as deceleration method and deceleration device thereof

A technology of reduction gear and rotary machine, which is applied in the direction of measuring devices, mechanical equipment, and mechanical parts testing, etc., and can solve problems such as electrical reduction gear and motor damage, unstable noise, and damage to the deceleration circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

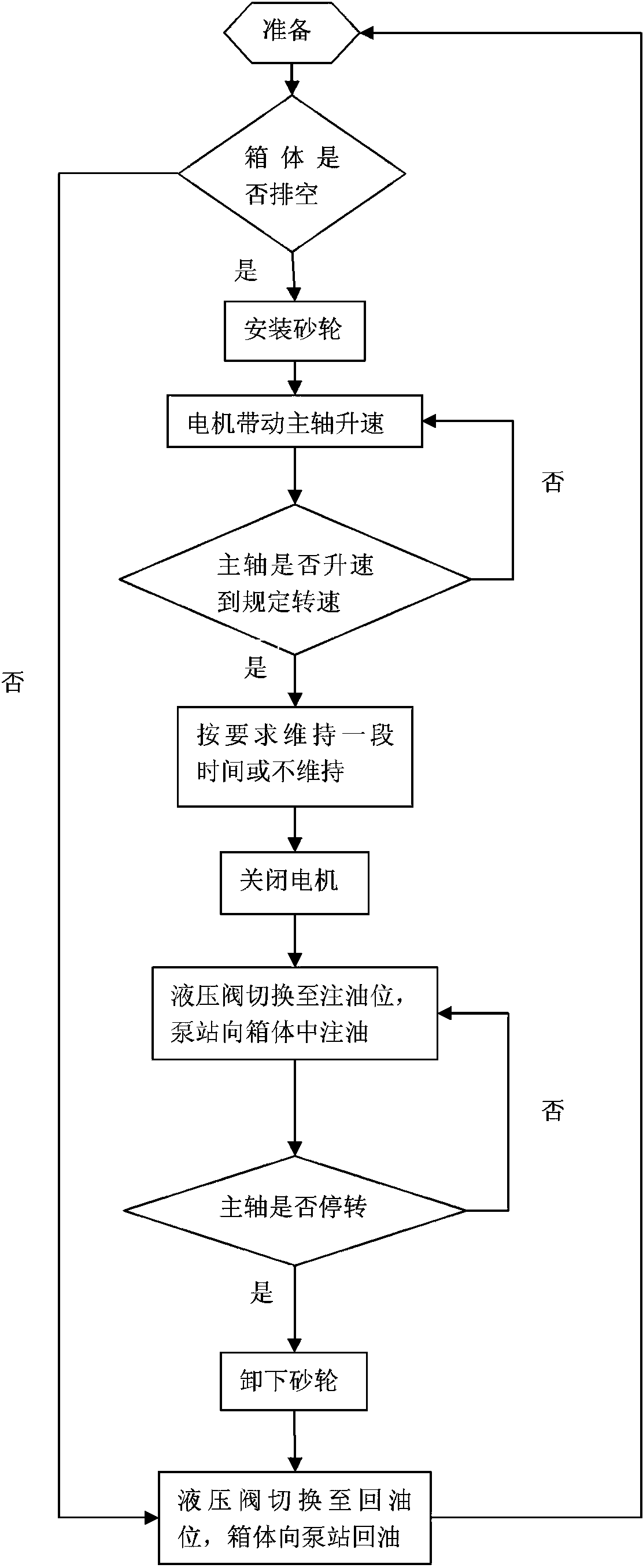

[0023] Embodiment of the deceleration method of rotary machine in the present invention: this deceleration scheme comprises the following steps:

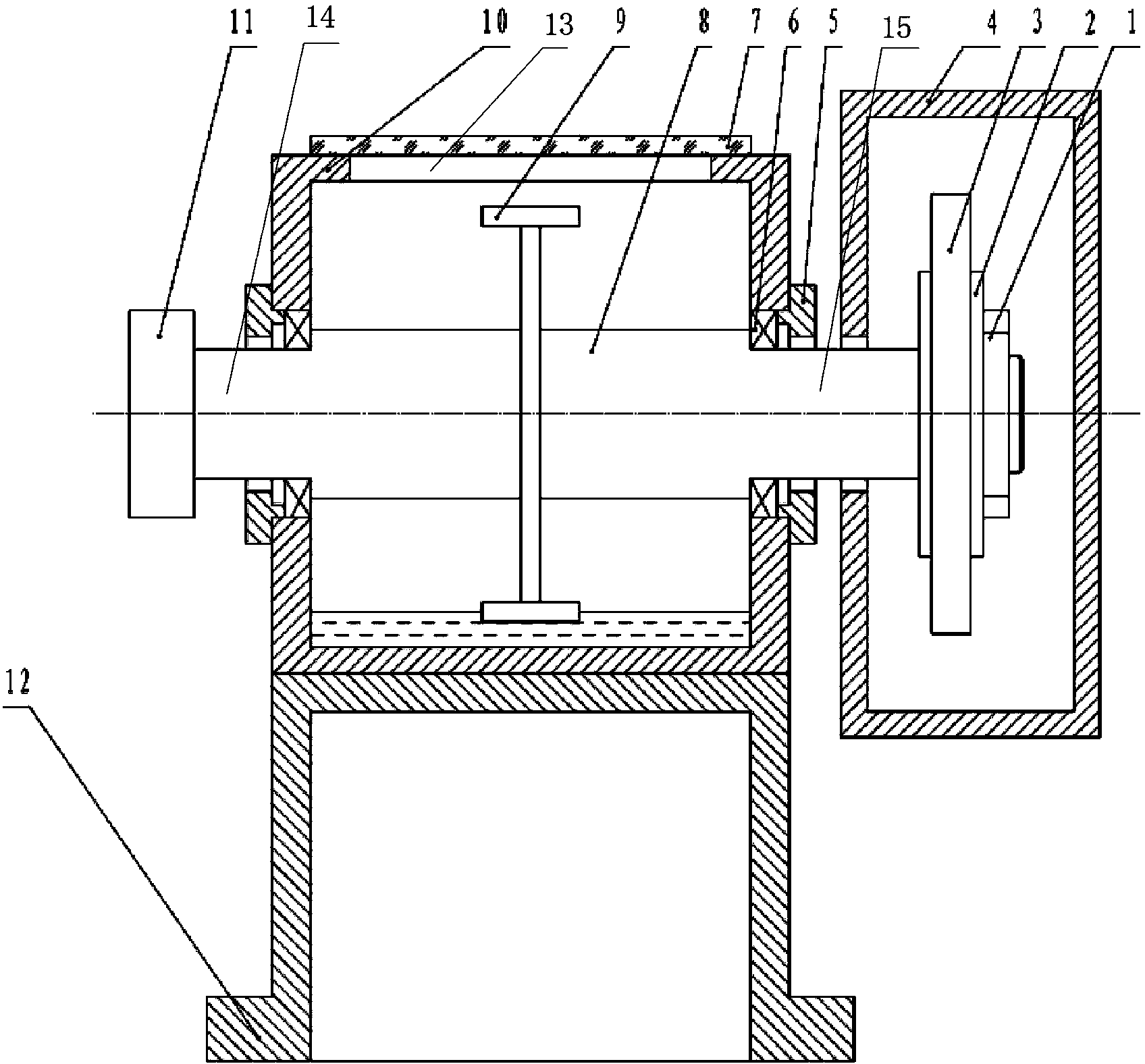

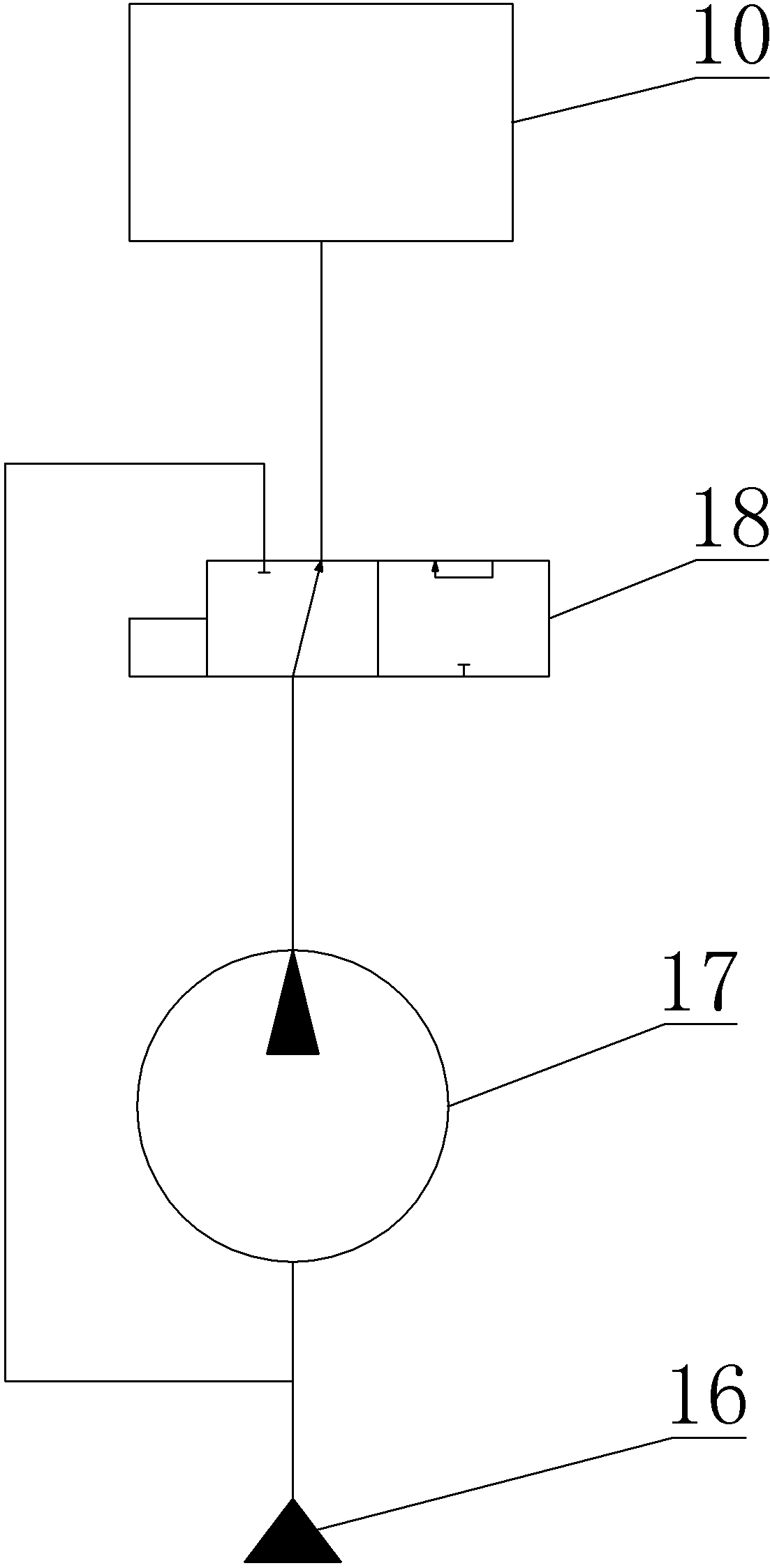

[0024] Step 1. Set the reduction shaft integrally connected with the main shaft of the rotary machine. The reduction shaft is located in the middle of the main shaft and rotates with the main shaft. The main shaft of the rotary machine includes a power input section and a grinding wheel installation section integrally connected at both ends of the reduction shaft. The power input section and the grinding wheel The installation section passes through the opposite sides of the container, and the deceleration shaft is relatively rotatable assembled on the container through the power input section and the grinding wheel installation section. The deceleration shaft is fixed with agitating paddles hanging on its outer periphery, and the agitation paddles In the container, there is a gap between the overhanging end of the stirring blade and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com