Calibration device for flat capacitive displacement sensor

A technology of displacement sensor and plate capacitor, which is applied in the field of sensor calibration, can solve the problems of small calibration stroke and limited sensor calibration accuracy, and achieve the effect of improving performance, easy operation, and small Abbe error and cosine error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

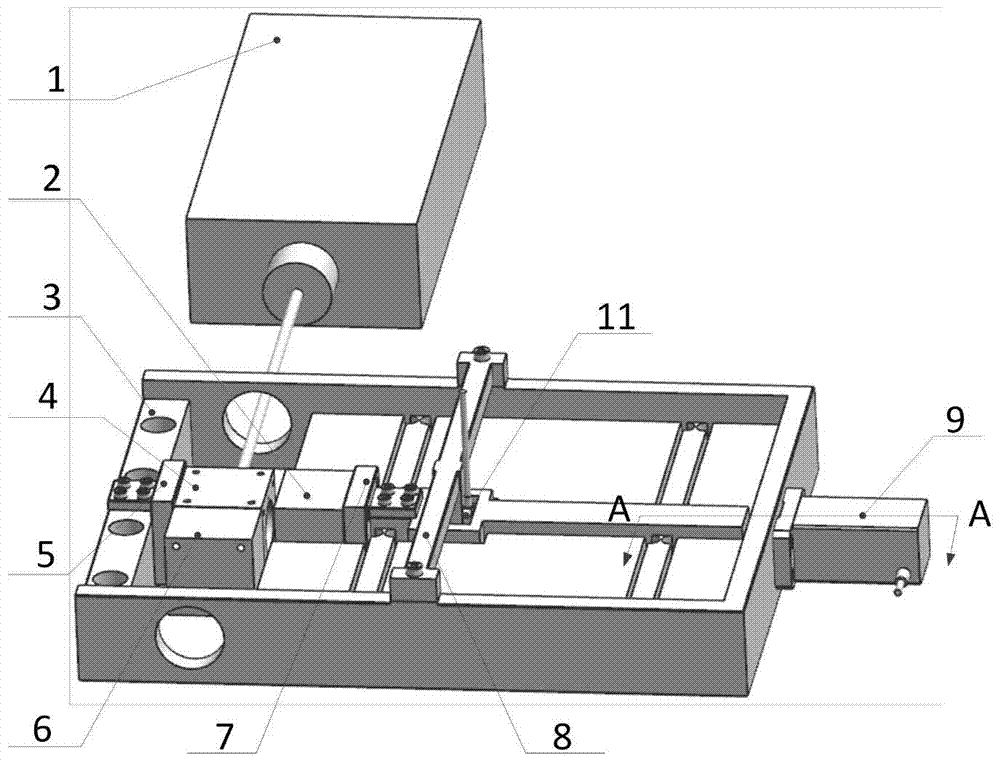

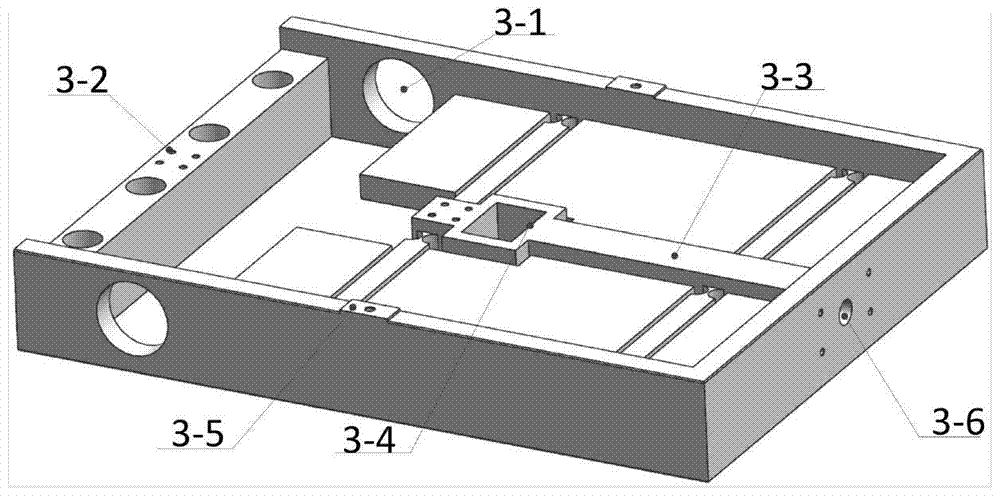

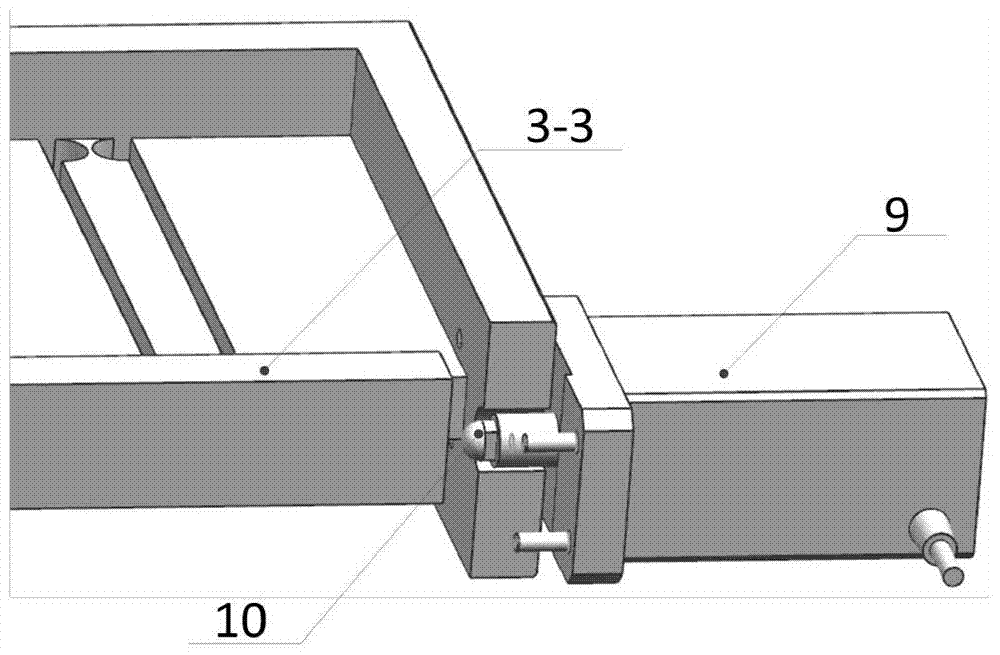

[0015] Such as Figure 1-2 As shown, the calibration device of the flat plate capacitive displacement sensor includes a micro-displacement adjustment mechanism 3, which is installed on the air-floating vibration isolation platform; the measuring beam emitted by the laser interferometer 1 passes through the light hole on the micro-displacement adjustment mechanism 3 3-1 is incident on the beam splitter 4, the beam splitter 4 is connected to the beam splitter support adjustment seat 5, and the beam splitter support adjustment seat 5 is connected to the beam splitter support adjustment seat interface 3-2 on the micro-displacement adjustment mechanism 3; refer to reflection The mirror 6 is connected with the beam splitter 4, and is on the same straight line as the optical axis of the laser interferometer 1; the measuring mirror 2 is connected with the measuring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com