Memristor based on pn heterostructure and manufacturing method thereof

A technology of heterostructure and memristor, which is applied in the field of information storage, can solve the problems of limiting the initial state of the device, the control space and flexibility of the memristive properties, etc., to achieve the effect of increasing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

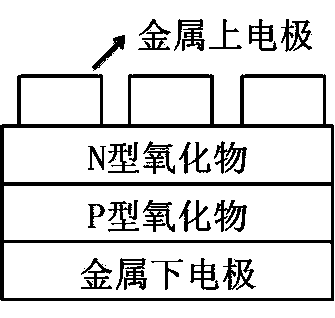

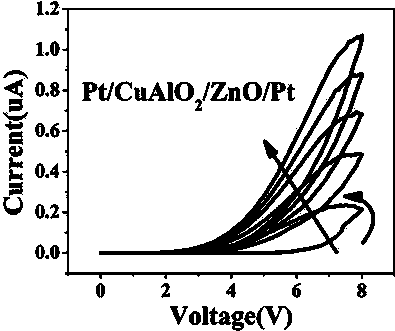

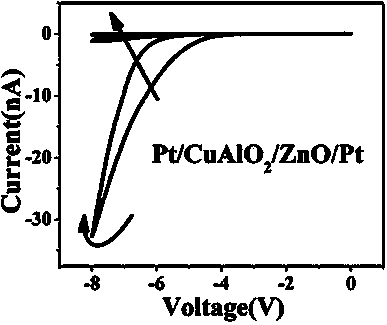

[0030] The structure and composition of Pn heterostructure memristor: as figure 1 The structure shown, in this embodiment, the upper and lower electrodes are made of inert metal Pt, and the p-type oxide is CuAlO 2 Thin films, n-type oxides are composed of ZnO thin films adhered in turn.

[0031] Preparation of the memristor: the 200nm inert metal Pt substrate is used as the bottom electrode after being cleaned by physical or chemical methods. On the lower electrode, a layer of p-type CuAlO was deposited by magnetron sputtering 2 Thin film, the thickness of the film is about 50 nanometers. The specific preparation conditions are: background vacuum: lower than 5.0×10 -4 Pa; sputtering gas: high-purity oxygen (O 2 ); growth pressure: 2Pa; sputtering target: CuAlO 2 Ceramic; sputtering power: 90W; substrate temperature: room temperature. After that, in the amorphous CuAlO 2 On the thin film, a layer of n-type ZnO thin film is also deposited by magnetron sputteri...

Embodiment 2

[0034] The structure and composition of Pn heterostructure memristor: as figure 1 As shown in the structure, in this embodiment, the lower electrode is made of inert metal Pt, the p-type oxide is NiO thin film, the n-type oxide is ZnO thin film, and the metal upper electrode Au is adhered in sequence.

[0035] Preparation of the memristor: the 200nm inert metal Pt substrate is used as the bottom electrode after being cleaned by physical or chemical methods. On the lower electrode, deposit a layer of p-type NiO thin film by magnetron sputtering method, and the film thickness is about 60 nanometers. The specific preparation conditions are: background vacuum: lower than 5.0×10 -4 Pa; sputtering gas: high-purity oxygen (O 2); growth pressure: 2Pa; sputtering target: NiO ceramics; sputtering power: 120W; substrate temperature: room temperature. Afterwards, on the NiO film, a layer of n-type ZnO film was also deposited by magnetron sputtering, with a film thickness of about 60 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com