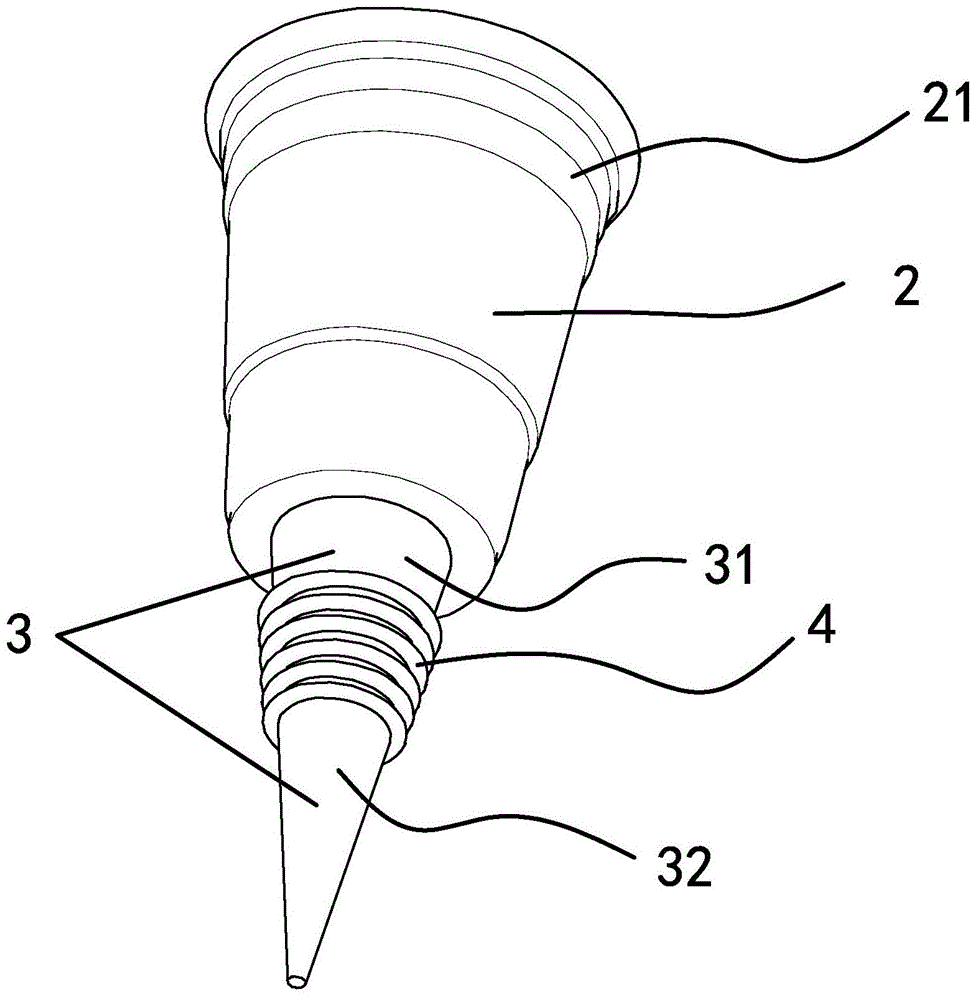

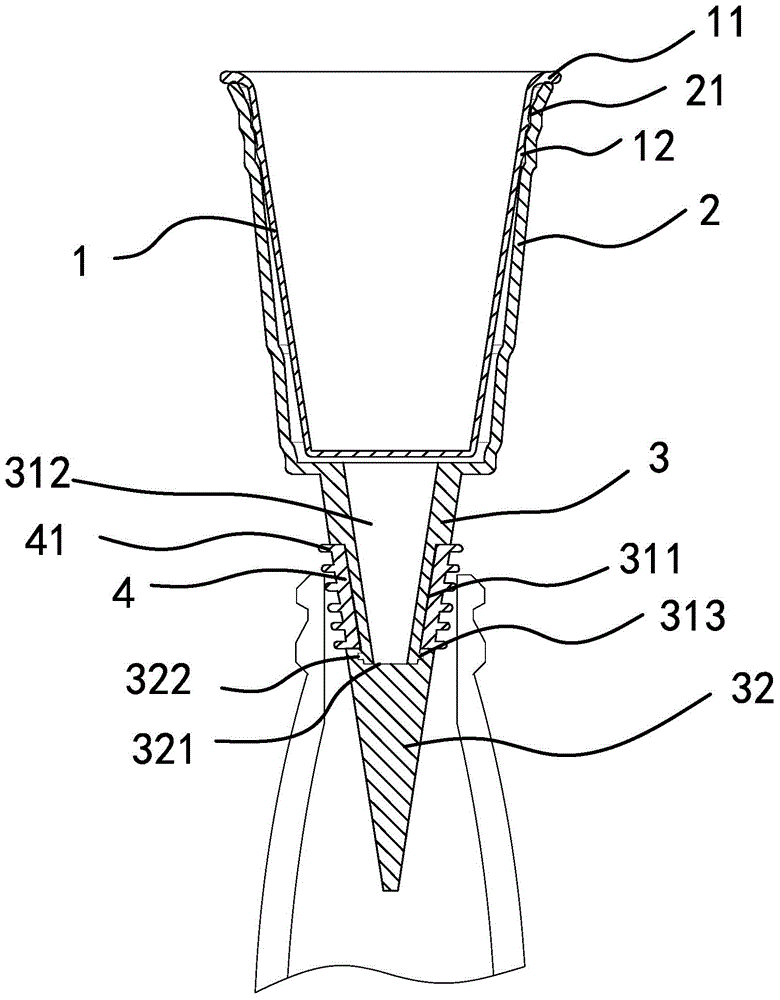

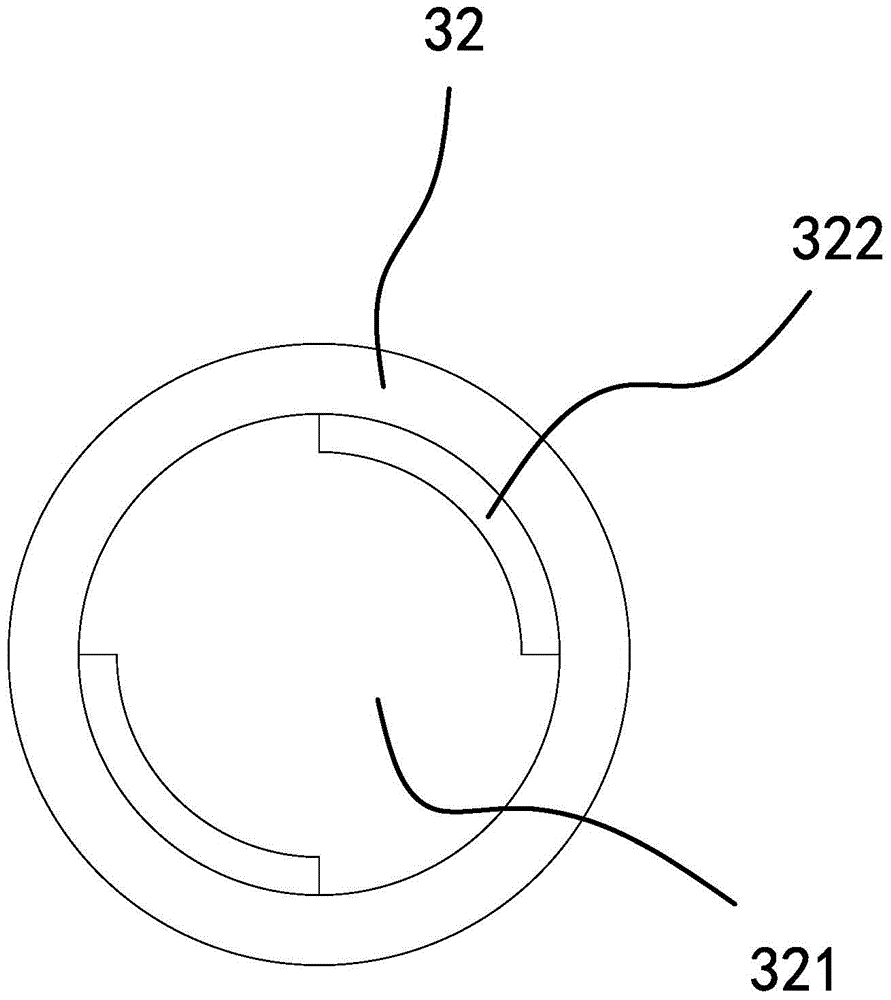

Bottle top cup

A cup body and inner cup body technology, applied in the field of bottle top cups, can solve the problems of weak clamping, leakage sealing, product deterioration, etc., and achieve the effects of good sealing effect, stable temperature resistance and good compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the composition and parts by weight of the composite rubber sealing ring in the bottle-top cup as follows, the raw materials are weighed: silicone rubber: 50 parts, acrylate rubber (ACM): 30 parts, ethylene-propylene-diene rubber (EPDM): 30 parts Parts, nano-calcium carbonate: 15 parts, plasticizer 3 parts, sulfur: 1 part, zinc oxide: 8 parts, stearic acid: 4 parts, anti-aging agent: 3 parts, wherein, the average particle diameter of the nano-calcium carbonate The average particle size of zinc oxide is 10nm, and the average particle size of zinc oxide is 3μm; mix the weighed raw materials through an internal mixer to form a rubber compound; The material punching die is pressurized, vulcanized, and finally the mold is opened to make the bottle top cup sealing ring. Wherein, the heating temperature is 35° C.; the initial temperature of the mold in the pressure-holding process of the rubber die is 100° C.; the pressure increases step by step during the pressur...

Embodiment 2

[0043] According to the composition and parts by weight of the composite rubber sealing ring in the bottle-top cup as follows, the raw materials are weighed: Silicone rubber: 40 parts, acrylate rubber (ACM): 40 parts, ethylene-propylene-diene rubber (EPDM): 20 parts Parts, nano-calcium carbonate: 25 parts, plasticizer 2 parts, sulfur: 0.5 parts, zinc oxide: 5 parts, stearic acid: 2 parts, anti-aging agent: 4 parts, wherein, the average particle diameter of described nano-calcium carbonate The average particle size of zinc oxide is 8nm, and the average particle size of zinc oxide is 2μm; mix the weighed raw materials through an internal mixer to form a rubber compound; The material punching die is pressurized, vulcanized, and finally the mold is opened to make the bottle top cup sealing ring. Wherein, the heating temperature is 30°C; the initial temperature of the mold in the pressure-holding process of the rubber die is 90°C; the pressure increases step by step during the pres...

Embodiment 3

[0045] Weigh the raw materials according to the composition and parts by weight of the composite rubber sealing ring in the bottle-top cup as follows: Silicone rubber: 60 parts, acrylic ester rubber (ACM): 20 parts, ethylene-propylene-diene monomer (EPDM): 40 parts Parts, nano calcium carbonate: 5 parts, plasticizer 5 parts, sulfur: 2 parts, zinc oxide: 10 parts, stearic acid: 2 parts, antioxidant: 2 parts, wherein, the average particle diameter of described nano calcium carbonate The average particle size of zinc oxide is 20nm, and the average particle diameter of zinc oxide is 5 μm; The raw materials that have been weighed are mixed by an internal mixer to prepare a mixed rubber; then the mixed rubber is thermally kneaded on an open mill to obtain a rubber compound, and then Pressurize and vulcanize the rubber material, and finally open the mold to make the bottle top cup sealing ring. Wherein, the heating temperature is 40°C; the initial temperature of the mold in the rubbe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap