Method for continuously supporting box support in medicine bottle packaging process and supporting machine

A technology for palletizers and palletizers, which is used in transportation and packaging, stacking of objects, and de-stacking of objects. The effect of a high degree of machine integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

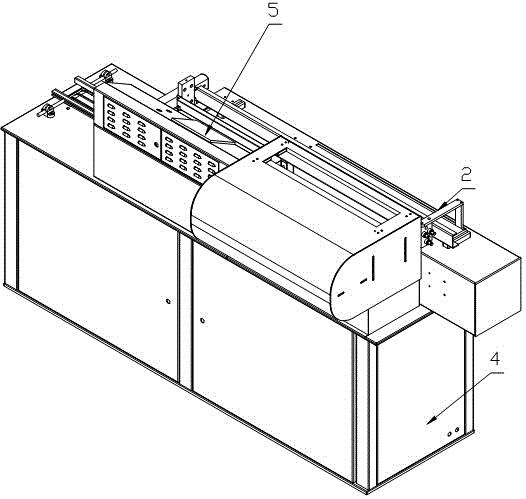

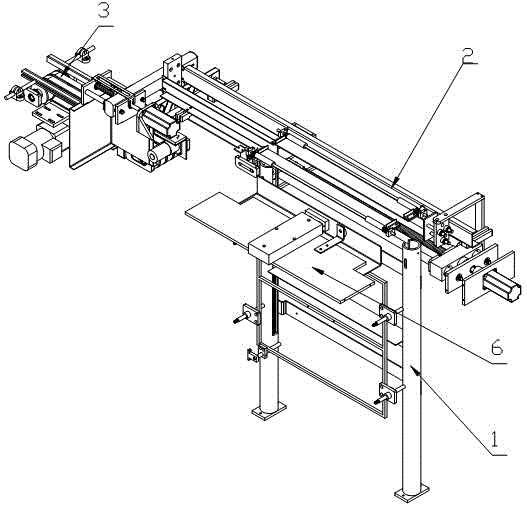

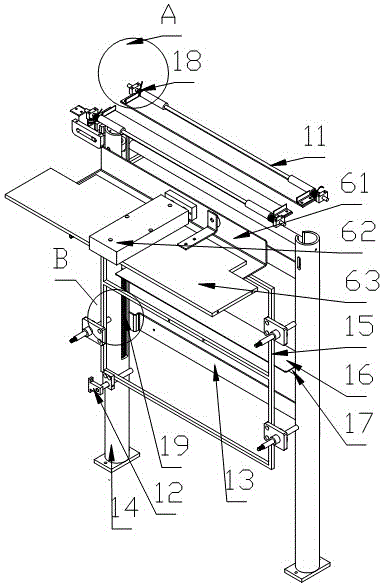

[0047] Embodiment 1: a kind of supporting machine, see Figure 1 to Figure 8 , the supporting machine includes a supporting module and a sub-supporting module successively, and also includes a supporting module 1 for preserving the box supporting and a pushing device 6 for releasing the inner box supporting of the supporting module 1 to the supporting module; 6 includes a cylinder 62, a cylinder frame 63 for fixing the cylinder 62, and a push plate 61 fixed to the piston end of the cylinder; the depository module 1 includes a depository bin 110 with an open top, and a lifting plate spanning the two ends of the depository bin 110 16 and the second power source that cooperates with lifting plate 16 to make its displacement.

[0048] In specific implementation, for the convenience of installation, the stainless steel square tube 17 is also provided under the lifting plate 16, and the outside of the spring 19 is covered with a spring placement tube 14. Since there are many boxes i...

Embodiment 2

[0064] Embodiment 2: The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that the second power source of the suction mechanism is replaced by a motor, and the suction head of the separation machine is hinged with the piston end of the cylinder. Connected and equipped with a reset device.

Embodiment 3

[0065] Embodiment 3: The principle of this embodiment is the same as that of Embodiment 1, and the specific difference is that: the lifting plate 16 across the two ends of the storage bin 110 and the second power source that cooperates with the lifting plate 16 to make its displacement be replaced by manual shaking or The motor drive makes it rise, that is to say, it is still put into the storage bin 110 in batches, but each lifting is manually shaken or driven by a motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com