Tower crane safety monitoring system and monitoring method

A safety monitoring system and tower crane technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problem of overlapping tower crane operation planes, restricting the monitoring safety of tower cranes, and restricting the monitoring safety factor of tower cranes, etc. problem, achieve the effect of shortening work time, convenient calculation, and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] For ease of description, the present invention will be described in further detail below in conjunction with the accompanying drawings.

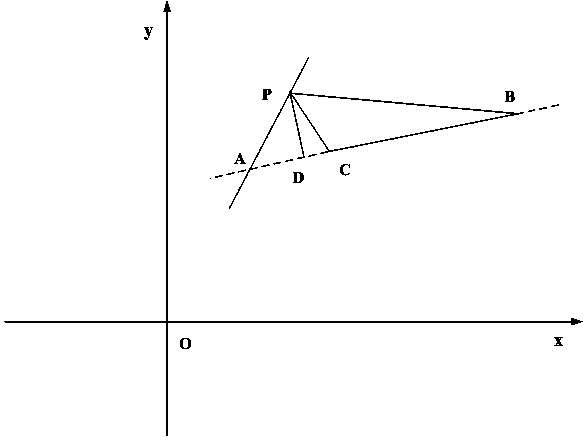

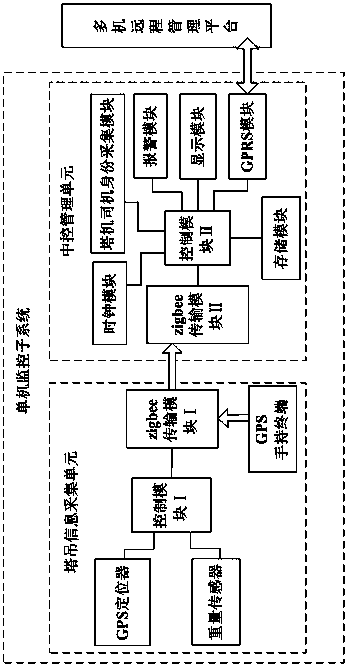

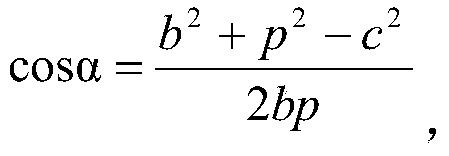

[0047] Such as figure 1 The shown tower crane safety monitoring system includes a stand-alone monitoring subsystem and a multi-machine remote management platform. The stand-alone monitoring subsystem includes a tower crane information collection unit and a central control management unit installed in the cab; the tower crane information collection unit includes: GPS Locator, installed on the hook of the tower crane, used to collect the position parameters of the tower crane hook, and send the collected results to the control module Ⅰ in real time, connected with the control module Ⅰ through wires; GPS handheld terminal, used to collect the current tower The GPS coordinates of the slewing center of the tower crane and the GPS coordinates of the boom end of the current tower crane, and the collected results are sent to the control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com