Electrodialysis oxidation method diaphragm sheet frame sludge dewatering machine

A sludge dewatering machine and sludge technology are applied in the oxidation treatment of sludge, dewatering/drying/concentrating sludge treatment and other directions, which can solve the problems of adding large lime, expensive sludge transportation and treatment costs, and unfavorable treatment. The effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

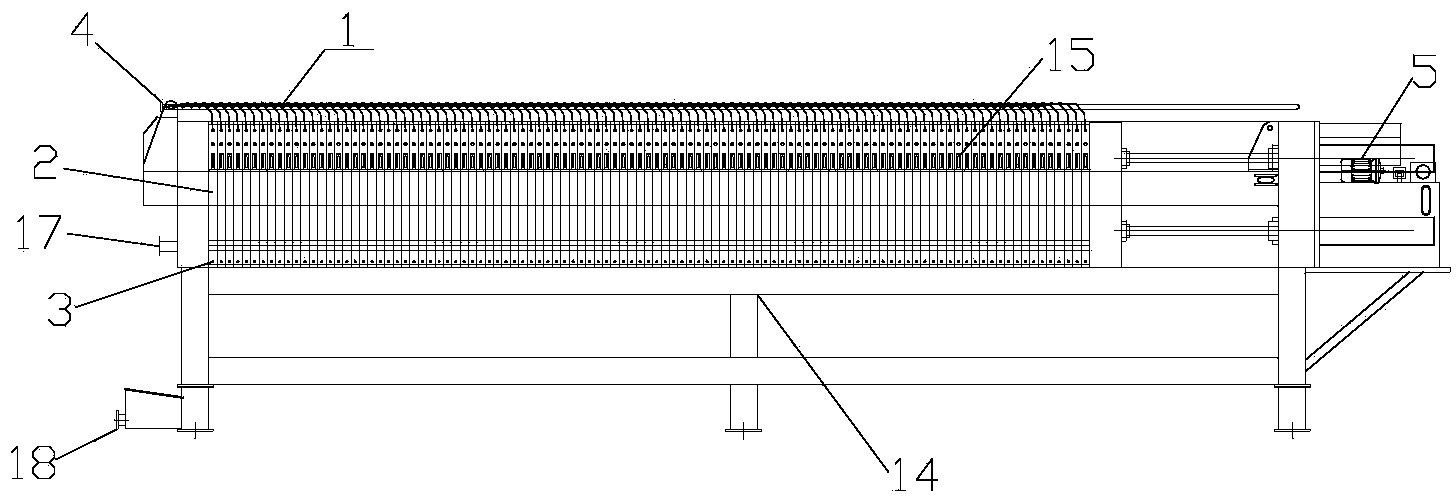

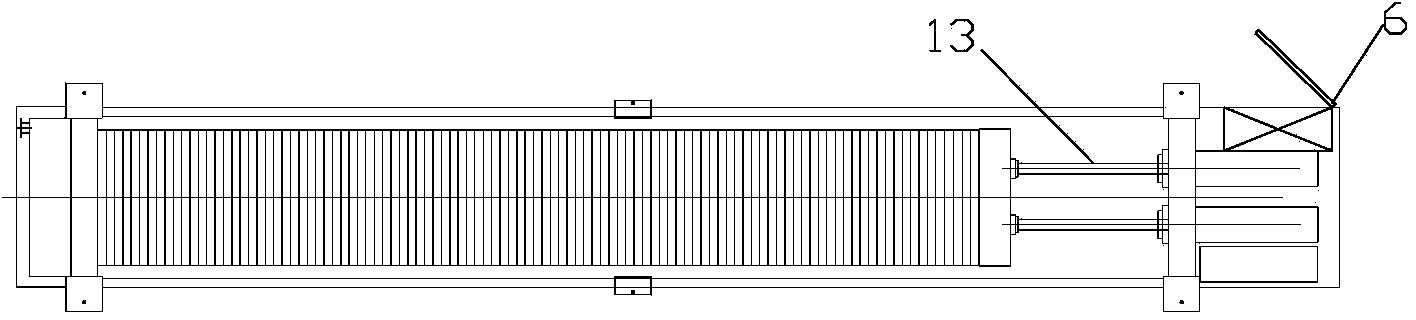

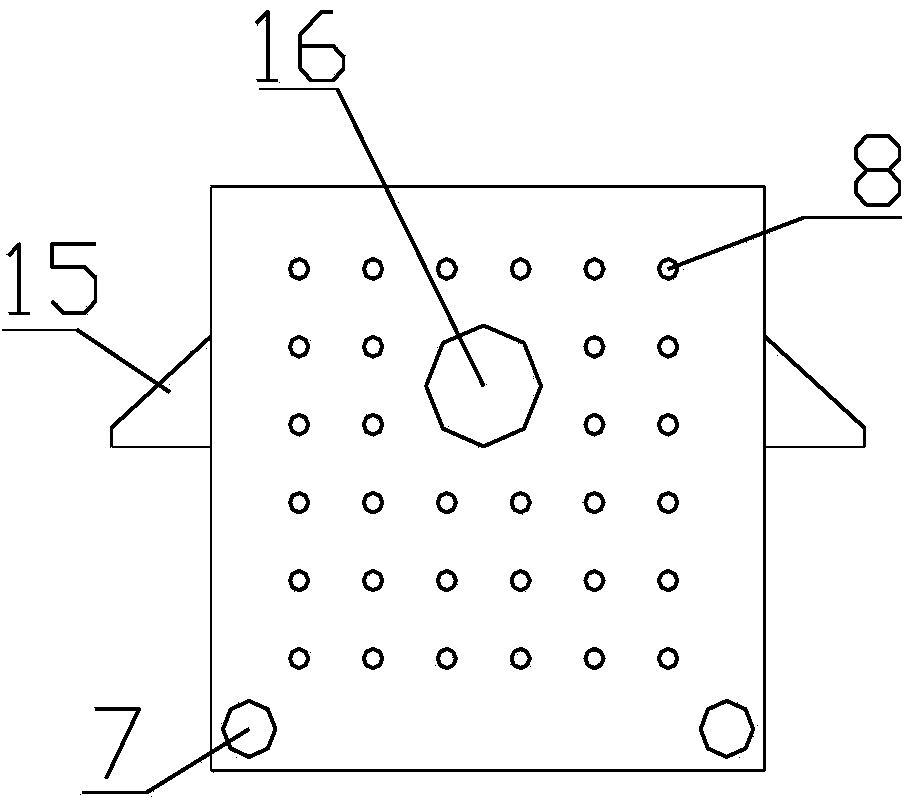

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The electrodialysis oxidation diaphragm plate frame sludge dewatering machine of the present invention includes a main frame 14, a filter plate 2, an electric control box 6, a squeeze water main pipe 1 and a squeeze water pipe branch 4, a hydraulic device 5 and a hydraulic rod 13. The filter plate includes drainage holes 7, rare earth metal sheets 8, DC wires 9, filter plate side membranes 10, metal electrodes 11, press water return holes 3, sludge inlet 17 and water outlet 18.

[0024] A plurality of filter plates 2 are suspended on the main frame 14 in parallel through hanging ears 15 . The electric control box 6 controls the hydraulic device 5 to push the hydraulic rod 13 of the hydraulic device 5 to squeeze the filter plate 2 arranged on the main frame 14 . The filter plate 2 is made of rubber casting, with good flexibili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com