A micro-negative pressure biomass gasifier with adjustable feed

A technology of gasifier and biomass, which is applied in the direction of manufacturing combustible gas, chemical industry, climate sustainability, etc. It can solve the problems of limited feed amount of biomass and uncontrollable combustion degree, so as to avoid gas leakage, Effect of improving flammability and improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

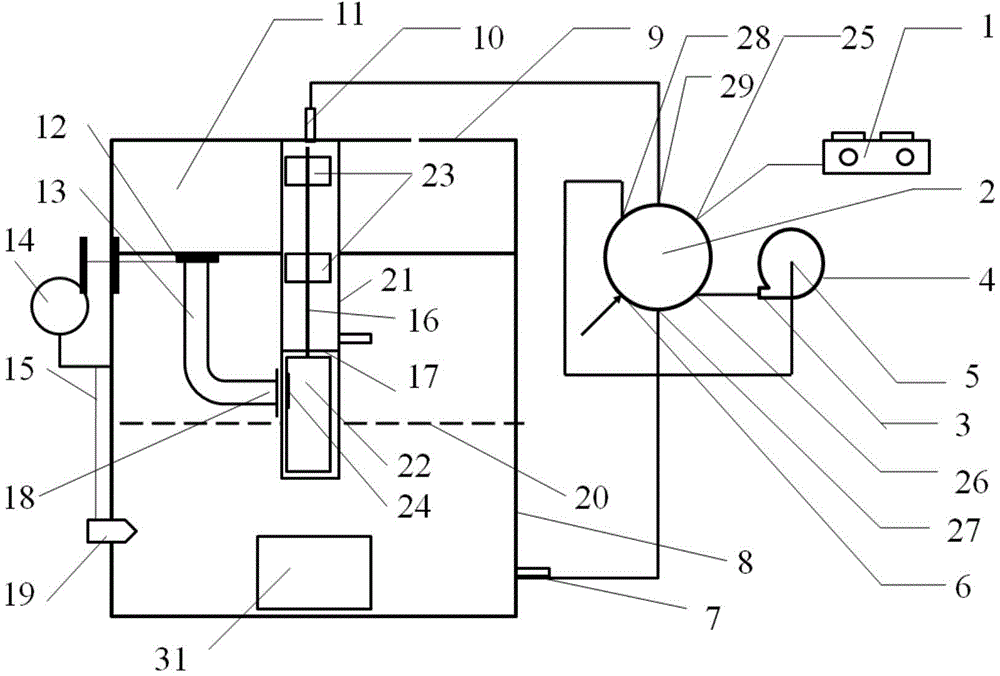

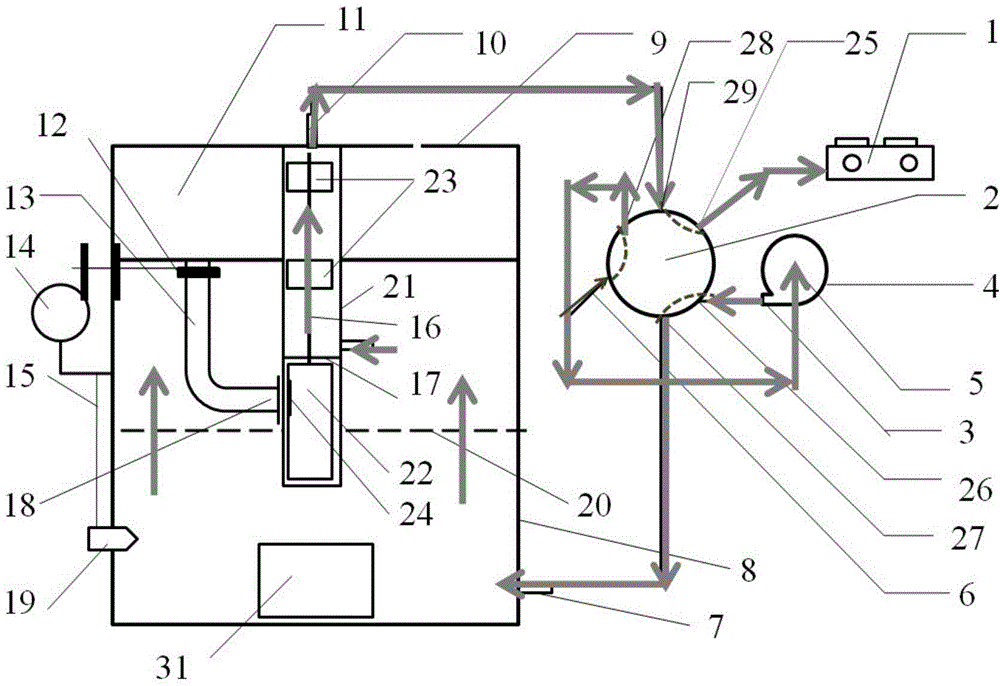

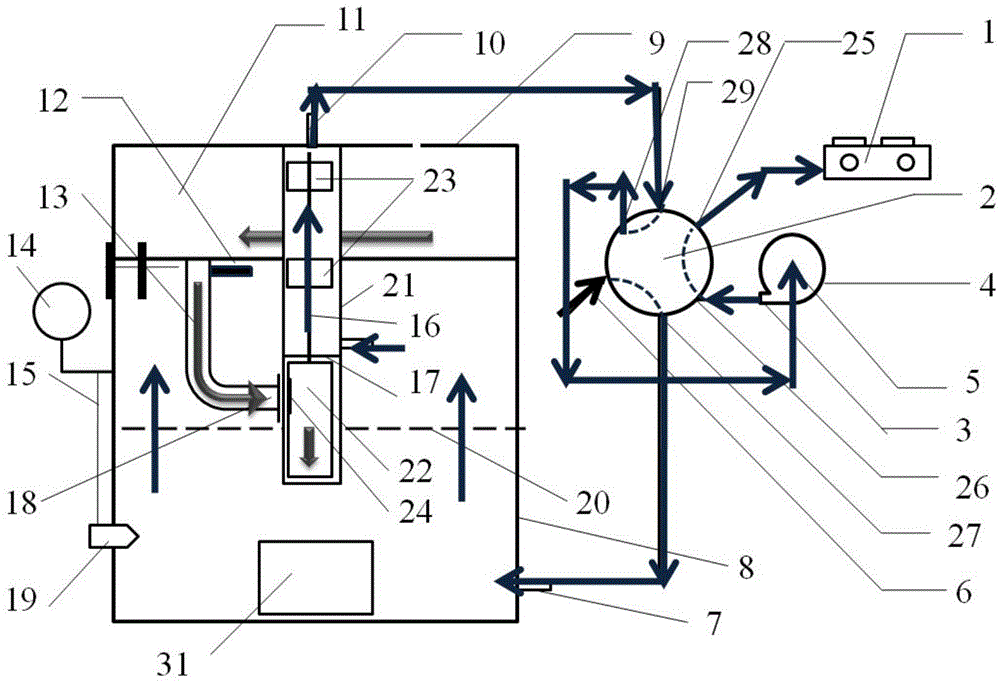

[0023] The present invention will be further described below with reference to the accompanying drawings.

[0024] Such as figure 1 , figure 2 As shown, a micro-negative pressure biomass gasifier with adjustable feed consists of a stove 1, a centrifugal fan 4, a gasifier body 8, a feed trough 11, a positive pressure cut-off valve 12, and a biomass feed Tube 13, contact vacuum gauge 14, combustion chamber 31, gas-solid feeding linkage device 21, partition 20, negative pressure regulating valve 19 and six-way valve 2,

[0025] When the gasification furnace provided by the present invention is ignited, the interface 25 of the six-way valve 2 is connected to the suction port 5 of the centrifugal fan 4, and the exhaust port 3 of the centrifugal fan 4 is connected to the gasification port 2 through the six-way valve 2, the interface 26 and the interface 27. The lower end of the furnace body 8 is connected to the intake pipe 7, and the combustion-supporting gas is introduced into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com