Steel making final slag adjustment and preparation method and application method thereof

A technology of regulator and final slag, which is applied in the manufacture of converters, etc., can solve the problems of large temperature drop of molten steel and high production cost, and achieve the effects of small temperature drop of molten steel, lower TFe content, and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the spherical particles can be carried out by various methods known in the art. For example, the mixture obtained by mixing MgO source, C source, Si source and Fe source can be fully mixed with the binder (according to needs, water can also be added), and then pressed by a ball press to form an average diameter of 20 to 60 mm. (preferably 30-40 mm) spherical particles, and then dried. The drying can be a well-known method in the art, for example, the obtained spherical particles can be dried at 200-300° C. for 1-2 hours.

[0025] According to the present invention, the added amount of the binder can be determined according to the weight of the mixture obtained by mixing the MgO source, the C source, the Si source and the Fe source. Usually, the added amount of the binder is 3-5.5% by weight, preferably 4-5.5% by weight, of the total weight of the mixture (a mixture of MgO source, C source, Si source and Fe source).

[0026] The adhesive can b...

Embodiment 1~4

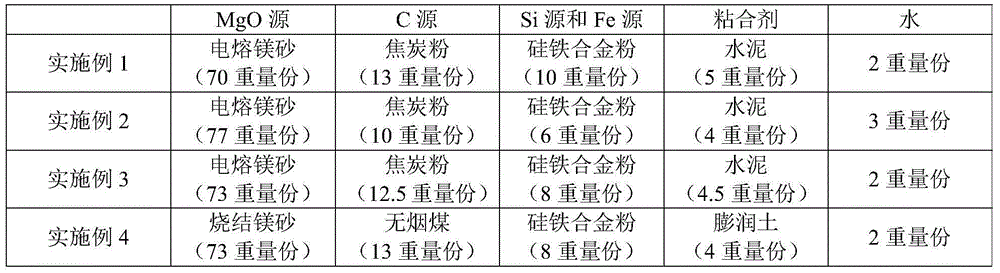

[0034] Mix the MgO source, C source, Si source and Fe source evenly to get the final slag modifier for steelmaking, and mix the final slag modifier for steelmaking with binder and water evenly, and make the average diameter 35mm spherical particles, and then dried at 250°C for 1.5 hours to obtain a granular final slag regulator for steelmaking. Wherein, the types and contents of the above-mentioned raw materials are shown in Table 1.

[0035] Table 1

[0036]

Embodiment 5

[0038] In a 120-ton converter, the molten steel intake and output is 130t. After the converter blowing is finished and before the steel is ready for tapping, the final slag regulator for steelmaking obtained in Example 1 is added, and the amount added is 2 kg per ton of molten steel. After sampling and analysis, the TFe content in the slag dropped from 24% by weight to 20% by weight. In addition, the temperature of molten steel dropped from 1680°C to 1678°C, almost unchanged. In addition, the oxidizability of the slag is effectively reduced, and the components in the molten steel meet the steel composition requirements after tapping is completed, and the final slag splashing effect of the converter is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com