Photomultiplier tube homogeneity testing system and testing method based on galvanometer

A photomultiplier tube and testing system technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of difficult batch detection of PMT uniformity, difficulty in ensuring accurate illumination, low light source displacement accuracy, etc. The effect of correcting position, simple construction and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

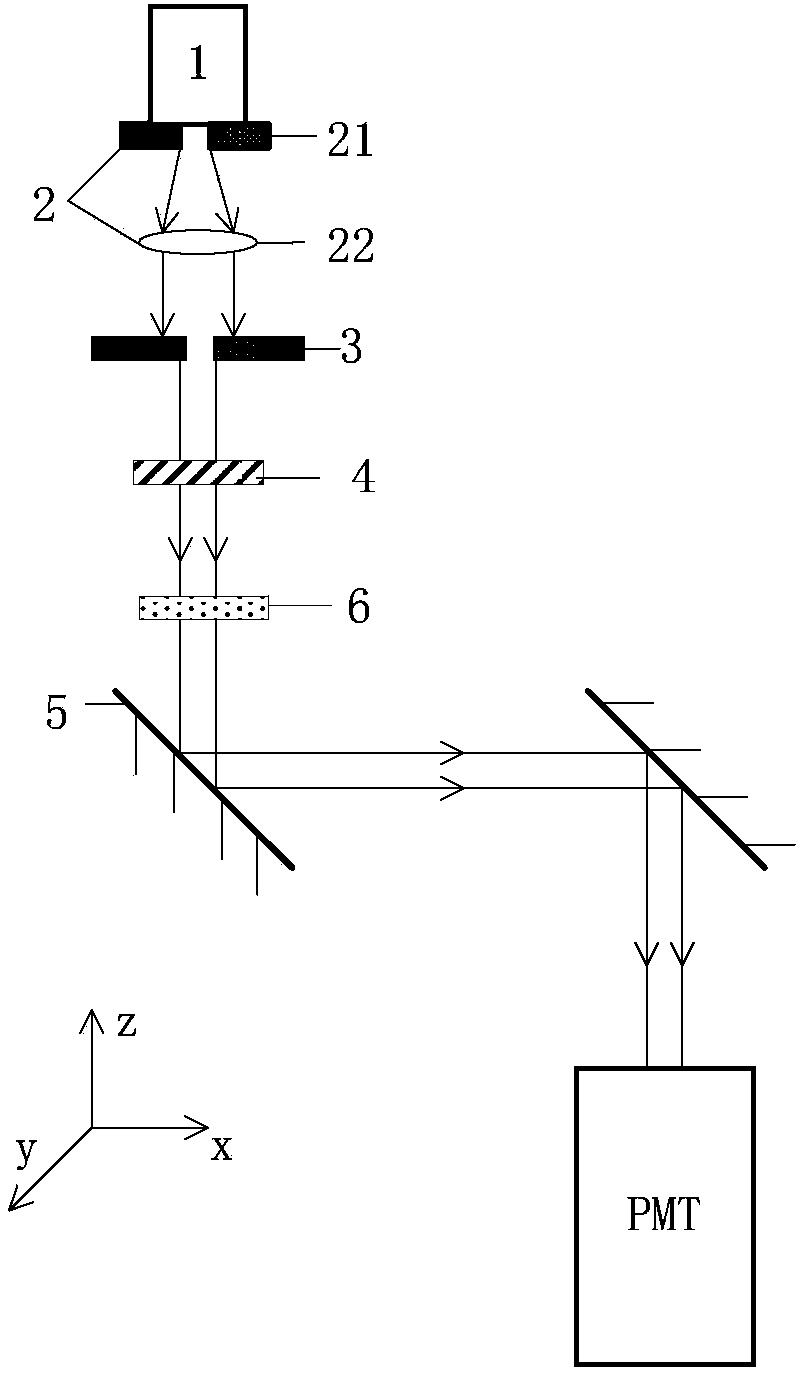

[0034] like figure 1 As shown, in this embodiment, the test system for the uniformity of the photomultiplier tube based on the galvanometer includes: a light source 1, a collimator 2, an aperture 3, an optical filter 4, a galvanometer 5, and a neutral density filter 6 And computer; Wherein, collimator 2 comprises collimating hole 21 and convex lens 22; Light source 1 sends the continuous light of divergence; After collimating hole 21, becomes parallel continuous light by convex lens 22, adjusts the diameter of light beam through diaphragm 3 , so that the diameter of the beam is slightly smaller than the diameter of the effective detection unit of the photomultiplier tube; the continuous light is converted into monochromatic light consistent with the fluorescence received by the photomultiplier tube through the filter; the beam is reflected by the galvanometer and incident on the photoelectric On the multiplier tube; the vibrating mirror includes two opposite mirrors, which are...

Embodiment 2

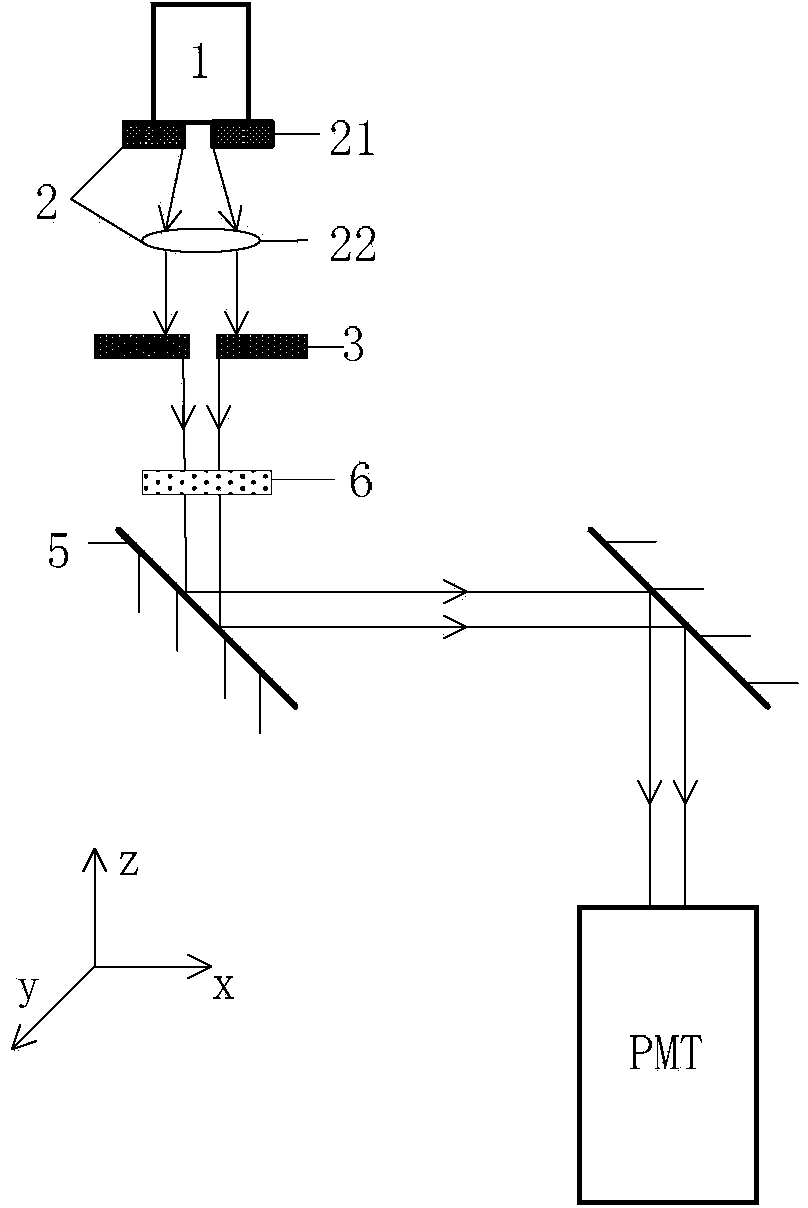

[0043] like figure 2 As shown, in this embodiment, the light source 1 adopts a monochromatic laser, and the wavelength is within the response range of the PMT, so there is no need to add an optical filter, and other structures are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com