Method for preparing Fen-flavor mouth-holding cigarette

A fragrant, snus technology, applied in the field of tobacco, can solve the problems of short shelf life, physical health threat, high moisture content, and achieve the effects of satisfying aroma preference, rich taste, and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a light-flavored snus, comprising the following steps:

[0027] Step 1. Select the fresh-flavor flue-cured tobacco leaves and place them in an oven at a temperature of 30-60°C for 2-12 hours, then crush and sieve the dried tobacco leaves to obtain 30-80 mesh tobacco powder; weigh Add 48-52 parts of tobacco powder in grams to 590-610 parts in milliliters of deionized water, soak for 0.5-3 hours, ultrasonically extract for 20-90 minutes, then filter to obtain the water extract, pass the water extract through water Obtain a water-oil azeotropic tobacco extract containing aroma components and nicotine by steam distillation, and then vacuum freeze-dry the tobacco extract at a temperature of -28 to -32°C for 18 to 108 hours to obtain a concentrated tobacco extract;

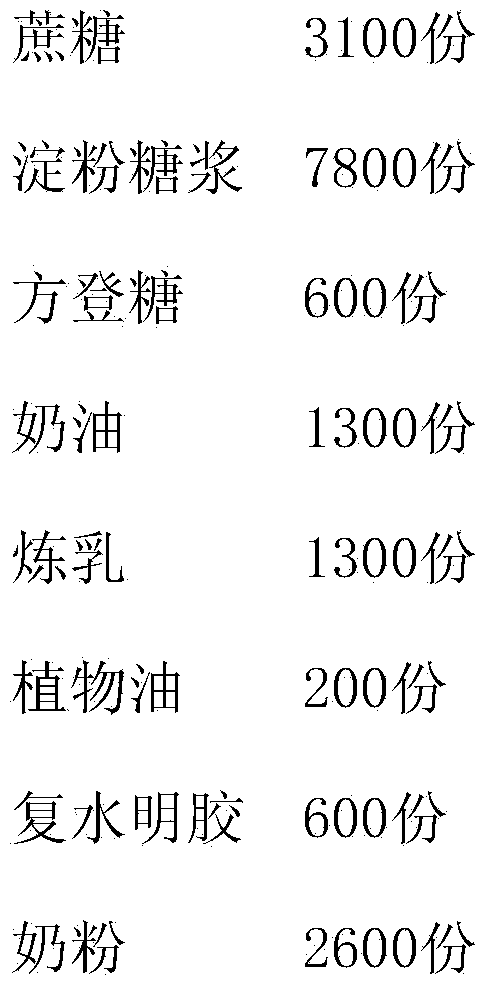

[0028] Step 2. Stir and dissolve sucrose and starch syrup with 500 parts of concentrated tobacco extract in milliliters at a temperature of 105°C, then boil, add butter, vegetable oil, and ...

Embodiment 2

[0031] A method for preparing a light-flavored snus, comprising the following steps:

[0032] Step 1. Select the fresh-flavor flue-cured tobacco leaves and place them in an oven at a temperature of 30-60°C for 2-12 hours, then crush and sieve the dried tobacco leaves to obtain 30-80 mesh tobacco powder; weigh Add 48-52 parts of tobacco powder in grams to 590-610 parts in milliliters of deionized water, soak for 0.5-3 hours, ultrasonically extract for 20-90 minutes, then filter to obtain the water extract, pass the water extract through The water-oil azeotropic tobacco extract containing aroma components and nicotine is obtained by steam distillation, and then the tobacco extract is vacuum freeze-dried at a temperature of -28 to -32°C for 18 to 108 hours to obtain a concentrated tobacco extract;

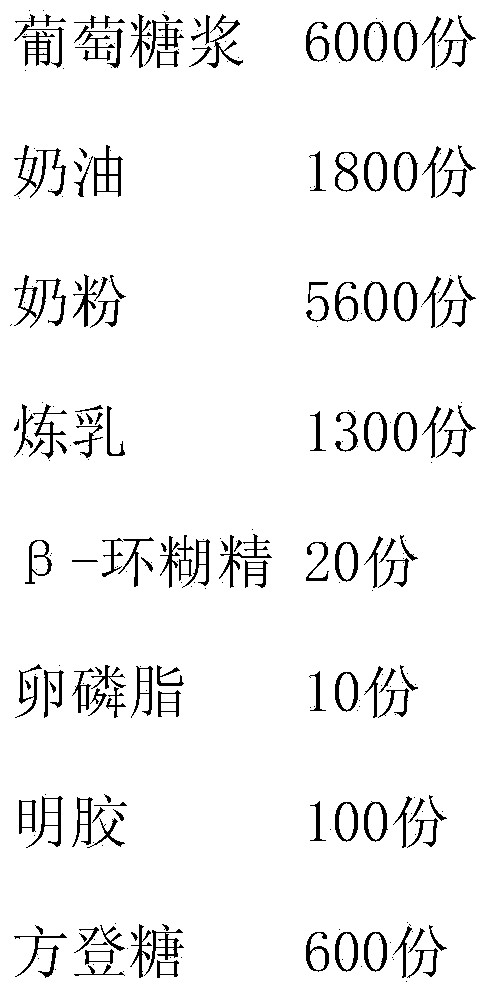

[0033] Step 2: (1) Sugar solution boiling: fully mix and dissolve 3600 parts of white granulated sugar in grams, 6000 parts of glucose syrup and 250 parts of concentrated tobacco extr...

Embodiment 3

[0039] A method for preparing a light-flavored snus, comprising the following steps:

[0040]Step 1. Select the fresh-flavor flue-cured tobacco leaves and place them in an oven at a temperature of 30-60°C for 2-12 hours, then crush and sieve the dried tobacco leaves to obtain 30-80 mesh tobacco powder; weigh Add 48-52 parts of tobacco powder in grams to 590-610 parts in milliliters of deionized water, soak for 0.5-3 hours, ultrasonically extract for 20-90 minutes, then filter to obtain the water extract, pass the water extract through The water-oil azeotropic tobacco extract containing aroma components and nicotine is obtained by steam distillation, and then the tobacco extract is vacuum freeze-dried at a temperature of -28 to -32°C for 18 to 108 hours to obtain a concentrated tobacco extract; The steam distillation method adopts heating and reflux for 70 to 300 minutes.

[0041] Step 2: (1) Sugar solution boiling: fully mix and dissolve 3900-4100 parts of sucrose in grams, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com