Separable microneedle system and manufacturing method thereof

A separate, micro-needle technology, which is applied in the direction of micro-needles, needles, and other medical devices, can solve the problems of uncontrollable drug release rate and drug loading, user discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

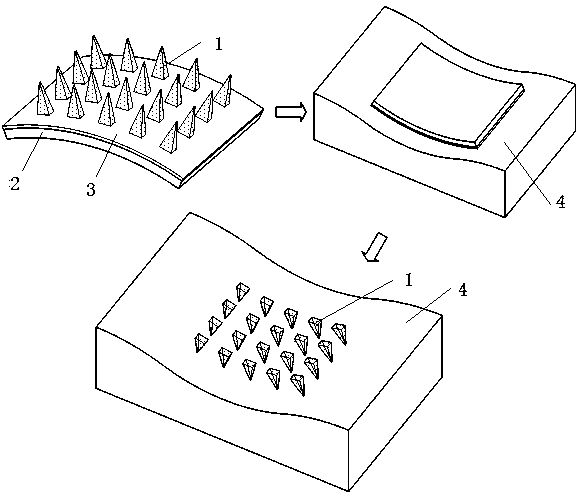

[0053] A method for manufacturing an adhesive detachable microneedle has the following steps:

[0054] (1) Making a microneedle array master mold 10 made of SU-8 material by photolithography;

[0055] a) Use AUTOCAD to draw the microneedle array base pattern, and make a mask. The microneedle base pattern of the microneedle array base pattern is 300 μm long, 200 μm wide, and the gap between the microneedles is 500 μm.

[0056] b) Prepare a K9 glass wafer as a glass substrate, and sputter a layer of 300 nm thick metal chromium (Cr) on the glass substrate;

[0057] c) Then spin-coat a layer of BP212-37s positive photoresist with a thickness of 2 microns, expose it with the mask made in step 1), develop it with 0.5% sodium hydroxide developer, and bake it at 100 °C for 5 minutes to obtain patterned photoresist mask;

[0058] d) Then use CR-14 etching solution to etch metal chromium (Cr), and then use acetone to remove the photoresist mask to obtain a Cr mask, so as to transfer t...

Embodiment 2

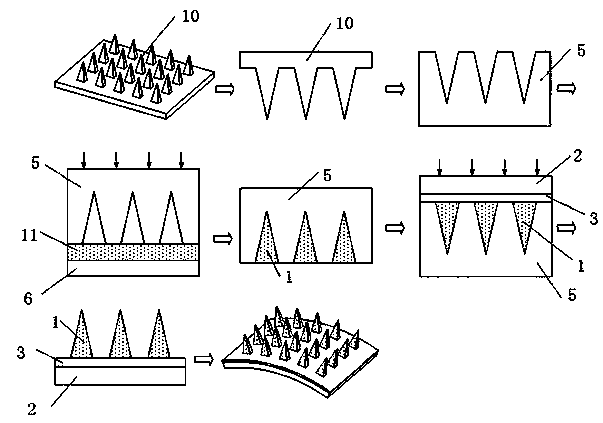

[0071] The manufacturing method of the needle groove type separable microneedle system has the following steps:

[0072] (1) Making a microneedle array master mold 10;

[0073] (2) Making a microneedle female mold 5;

[0074] (3) Filling the microneedle prepolymer solution in the microneedle groove of the microneedle female mold 5 and curing it;

[0075] (4) Press the microneedle female mold 5 on the viscous transfer plate 7 to transfer the microneedle 1 to the viscous transfer plate 7;

[0076] (5) Using the viscous transfer plate 7 to transfer the microneedle 1 to the transfer mold 8, the depth of the microneedle groove of the transfer mold 8 is smaller than the depth of the microneedle groove of the microneedle female mold 5;

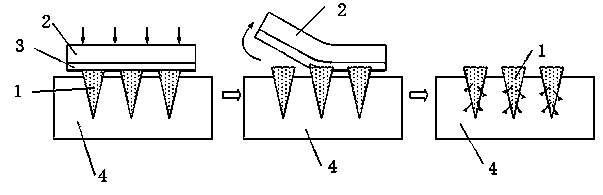

[0077] (6) Transfer the microneedles 1 in the transfer mold 8 to the substrate 2 engraved with needle grooves, insert the microneedles 1 into the needle grooves, and separate from the microneedle female mold 5 together with the substrate 2, and obt...

Embodiment 3

[0083] The manufacturing method of the multi-row assembled adhesive detachable microneedle system: (1) Use dissolvable materials such as silk fibroin and maltose materials to prepare coplanar microneedle arrays 9, and the thickness of the coplanar microneedle arrays 9 is less than Its width; (2) Multiple coplanar microneedle arrays 9 are vertically or obliquely embedded in the needle grooves of the substrate 2, the needle grooves correspond to the shape of the microneedle bases of the coplanar microneedle arrays 9, and are fixed with an adhesive to obtain different Planar microneedle arrays.

[0084]Such as Figure 7 As shown, the method of using the adhesive multi-row assembled separable microneedle system: (1) Squeeze the substrate 2 to make the coplanar microneedle array 9 penetrate the skin 4; (2) Translate the substrate 2 to make the coplanar microneedle array 9 Break at the bonding place; (3) The coplanar microneedle array 9 stays in the skin 4 after breaking and slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com