Method for eddy current sensing welding seam automatic following control of front dual probes

An automatic tracking, eddy current sensing technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of low manufacturing cost, difficult to guarantee accuracy, poor real-time performance, etc., to simplify the calculation process and circuit structure, reduce the system Cost, control the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

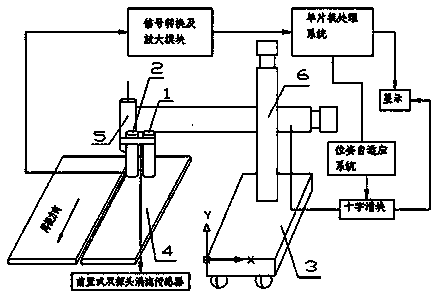

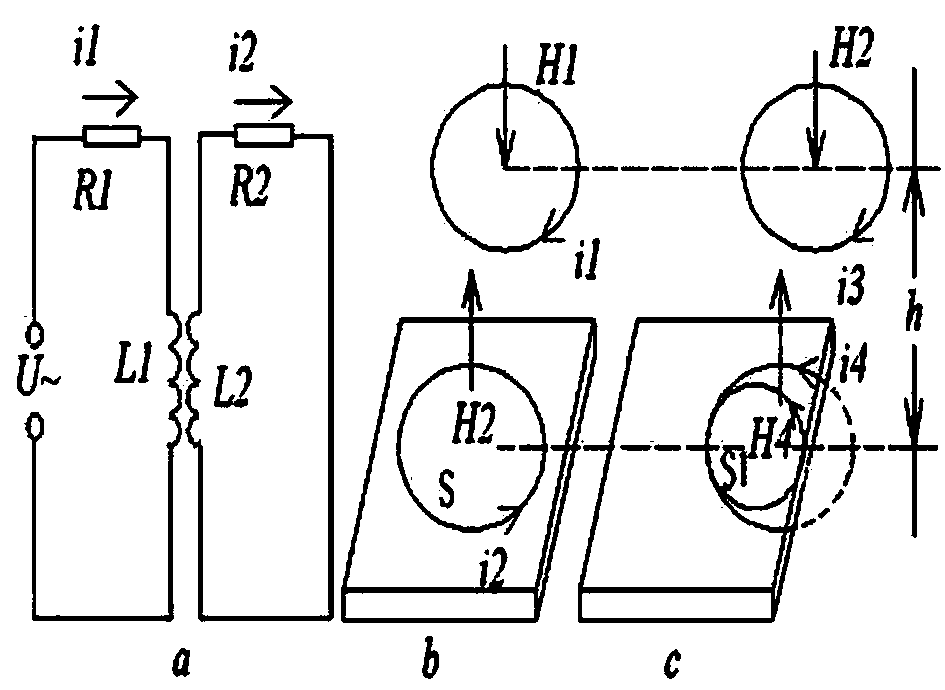

[0014] Embodiment 1. The present invention adopts a control system including a dual-probe eddy current sensor installed on a welding torch, a welding execution device and a welding control device, and combines the application of the non-contact linearized measurement characteristics of the dual-probe eddy current sensor to realize a dual-probe eddy current sensor. In the sensor-type welding seam automatic tracking control method, the welding execution device in the control system includes a welding power supply and a welding torch 5 connected to the welding control device. The welding torch 5 is aimed at the butt weld, that is, the butt metal plate 4. The welding control device mainly includes Double-probe eddy current sensor, pre-processor, welding trolley 3 and cross slider 6, the double-probe eddy current sensor is placed in front of the welding torch 5 and placed on the groove side, the double-probe eddy current sensor has two probes, and the probe Ⅰ1 passes through the heig...

Embodiment 2

[0015] Embodiment 2, the pre-processor is provided with a signal processing circuit, an A / H conversion circuit, a single-chip microcomputer processing circuit, and a drive control circuit to perform pre-processing on the input current. The signal collected by the double-probe eddy current sensor is converted into a voltage signal output. During the processing process, it is first processed by the signal processing circuit and the A / H conversion circuit, and then sent to the single-chip processing circuit for software processing and calculation. The single-chip processing circuit The adjustment signal is given and the welding actuator is controlled by the drive control circuit to achieve position control and real-time adjustment between the welding torch 5 and the workpiece-conductor surface, thereby realizing automatic welding seam tracking. refer to Figure 1 to Figure 2 , all the other are with embodiment 1.

Embodiment 3

[0016] Example 3, the two probes of the eddy current sensor can compensate each other, the voltage changes of the probe I1 and the probe II2 of the dual-probe eddy current sensor are used for surface fitting through lstopt, an appropriate surface equation is selected, and then the variables are separated, and the probe I1 is The height is compensated to the probe Ⅱ2, eliminating the influence of the distance H on the probe Ⅱ2, capturing the height and position information of the welding torch 5 and the weld seam, first converting the sampling signal into a digital signal and inputting it into the single-chip processing circuit, and then using Fuzzy according to the deviation of the weld seam —PID control adjusts the welding torch 5 to realize automatic tracking of the welding seam by the welding torch 5. refer to Figures 1 to 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com