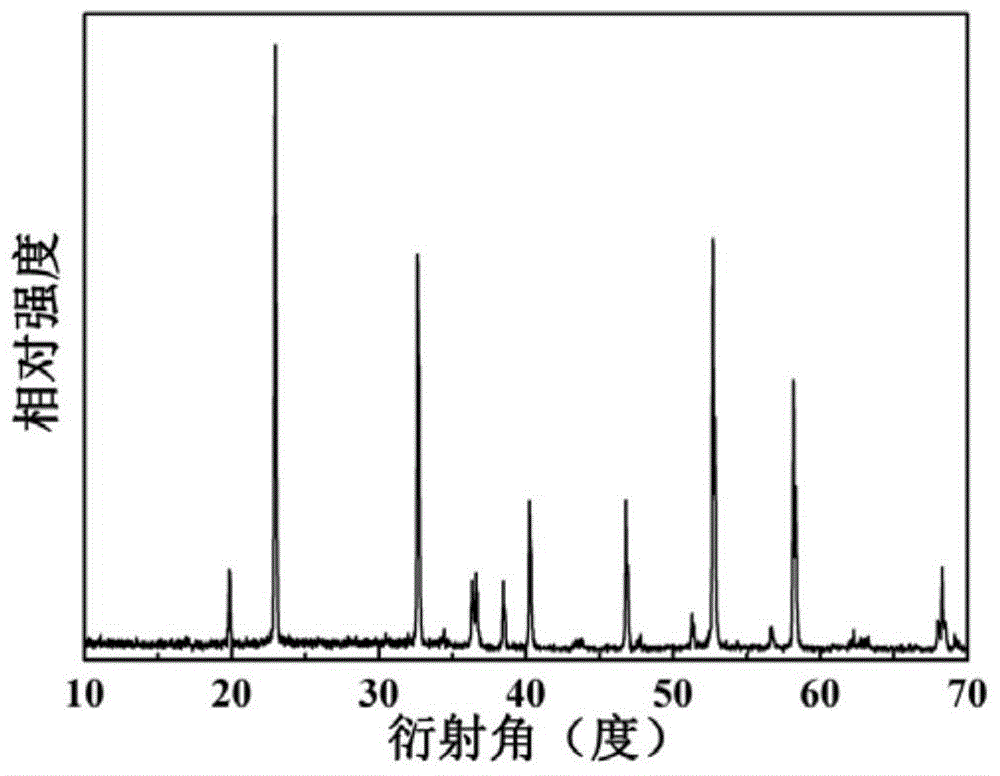

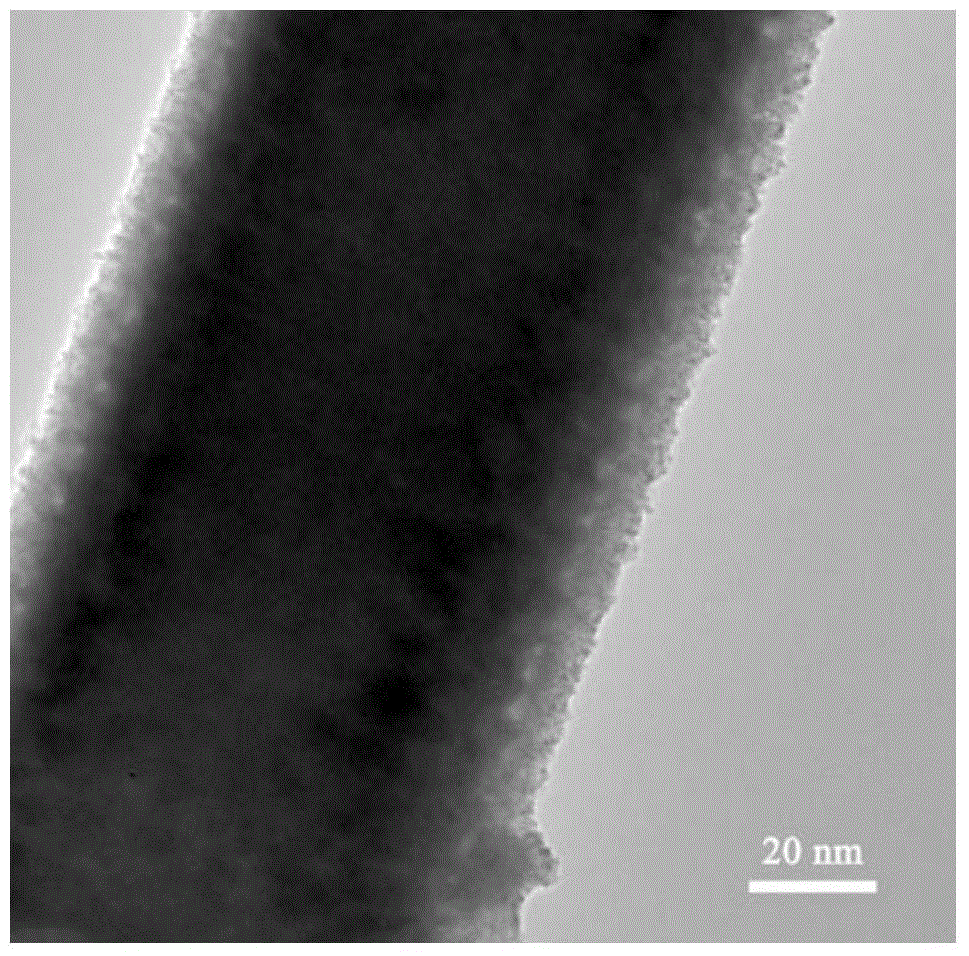

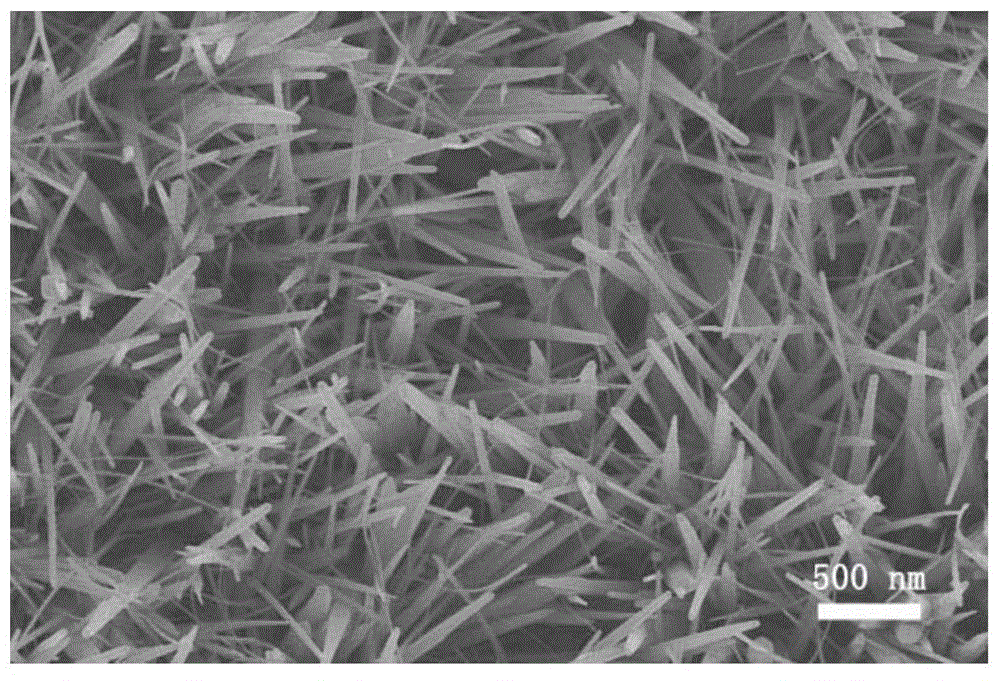

Preparation method of size-controllable zinc hydroxystannate nanorod arrays

A technology of zinc hydroxystannate and nanorod array, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of not meeting the expected requirements, and achieve uniform size, regular shape, Increased and active effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of zinc oxide. Coat the surface of the cleaned zinc sheet with a layer of butyl titanate, put it into a polytetrafluoroethylene autoclave with a concentration of 0.5 mol / liter sodium hydroxide solution, and heat it at a constant temperature of 180 degrees Celsius for 12 hours. The final zinc sheet is taken out, rinsed with absolute ethanol and deionized water in turn, and dried at 60-100 degrees Celsius for 6-12 hours;

[0028] (2) the zinc flakes obtained in the first step are put into the reaction solution mixed with raw material urea, potassium stannate and hydroalcoholic solution, the concentration of urea in the middle period is 0.1-0.5 mol / liter, and the concentration of potassium stannate The concentration is 0.01-0.05 mol / liter, and the volume of absolute ethanol in the hydroalcoholic solution is 30%;

[0029] (3) heating the above-mentioned solution at 60-70 degrees Celsius for 1-6 hours;

[0030] (4) Collect the zinc flakes obtained from the ...

Embodiment 2

[0032] (1) Preparation of zinc oxide. Coat the surface of the cleaned zinc sheet with a layer of butyl titanate, put it into a polytetrafluoroethylene autoclave with a concentration of 0.5 mol / liter sodium hydroxide solution, and heat it at a constant temperature of 180 degrees Celsius for 12 hours. The final zinc sheet is taken out, rinsed with absolute ethanol and deionized water in turn, and dried at 60-100 degrees Celsius for 6-12 hours;

[0033] (2) put the zinc sheet obtained in the first step into the reaction solution mixed with raw material urea, potassium stannate and hydroalcoholic solution, the concentration of urea in the middle period is 0.5-1.0 mol / liter, and the concentration of potassium stannate The concentration is 0.01-0.05 mol / liter, and the volume of absolute ethanol in the hydroalcoholic solution is 30%;

[0034] (3) heating the above-mentioned solution at 60-70 degrees Celsius for 1-6 hours;

[0035] (4) Collect the zinc flakes obtained from the react...

Embodiment 3

[0037] (1) Preparation of zinc oxide. Coat the surface of the cleaned zinc sheet with a layer of butyl titanate, put it into a polytetrafluoroethylene autoclave with a concentration of 0.5 mol / liter sodium hydroxide solution, and heat it at a constant temperature of 180 degrees Celsius for 12 hours. The final zinc sheet is taken out, rinsed with absolute ethanol and deionized water in turn, and dried at 60-100 degrees Celsius for 6-12 hours;

[0038] (2) the zinc flakes obtained in the first step are put into the reaction solution mixed with raw material urea, potassium stannate and hydroalcoholic solution, the concentration of urea in the middle period is 0.1-0.5 mol / liter, and the concentration of potassium stannate The concentration is 0.01-0.05 mol / liter, and the volume of absolute ethanol in the hydroalcoholic solution is 30%;

[0039] (3) heating the above-mentioned solution at 60-70 degrees Celsius for 9-12 hours;

[0040] (4) Collect the zinc flakes obtained from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com