Diffusion agricultural film

An agricultural film and diffusion technology, which is applied in the field of agricultural film formulations, can solve problems such as damage to concave and convex parts, and achieve the effects of reducing damage, increasing yield, and reducing shadow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Diffuse masterbatch is prepared according to the following formula in weight ratio:

[0024] LDPE: 7.5 parts; LLDPE: 2.5 parts; Zinc oxide: 1 part; Talc powder: 1 part; Magnesium stearate: 0.5 parts; Polyethylene wax: 0.3 parts.

[0025] Preparation method of agricultural film: Stir the well-proportioned masterbatch evenly, so that all the additives evenly adhere to the surface of the plastic, put it on the extruder, extrude and granulate. Using LDPE as the matrix resin, blow molding is carried out according to the ratio of masterbatch: matrix resin = 1:20, and the thickness of the prepared film is 0.03mm. Before blow molding, phthalocyanine blue dye, dripping agent and anti-ultraviolet agent are added, so that the prepared agricultural film has high-performance agricultural film with blue color, anti-dripping and anti-aging properties while scattering and penetrating sunlight.

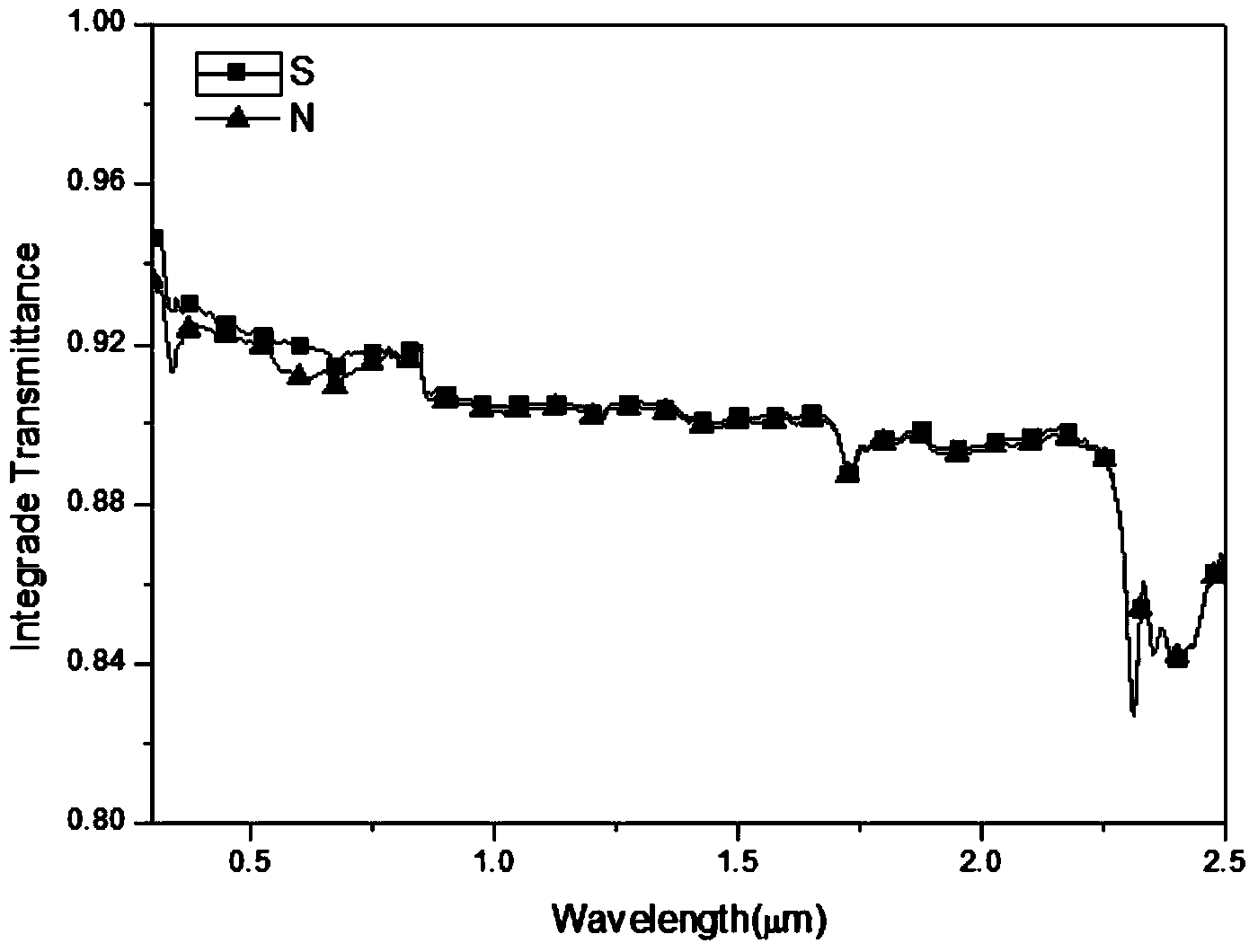

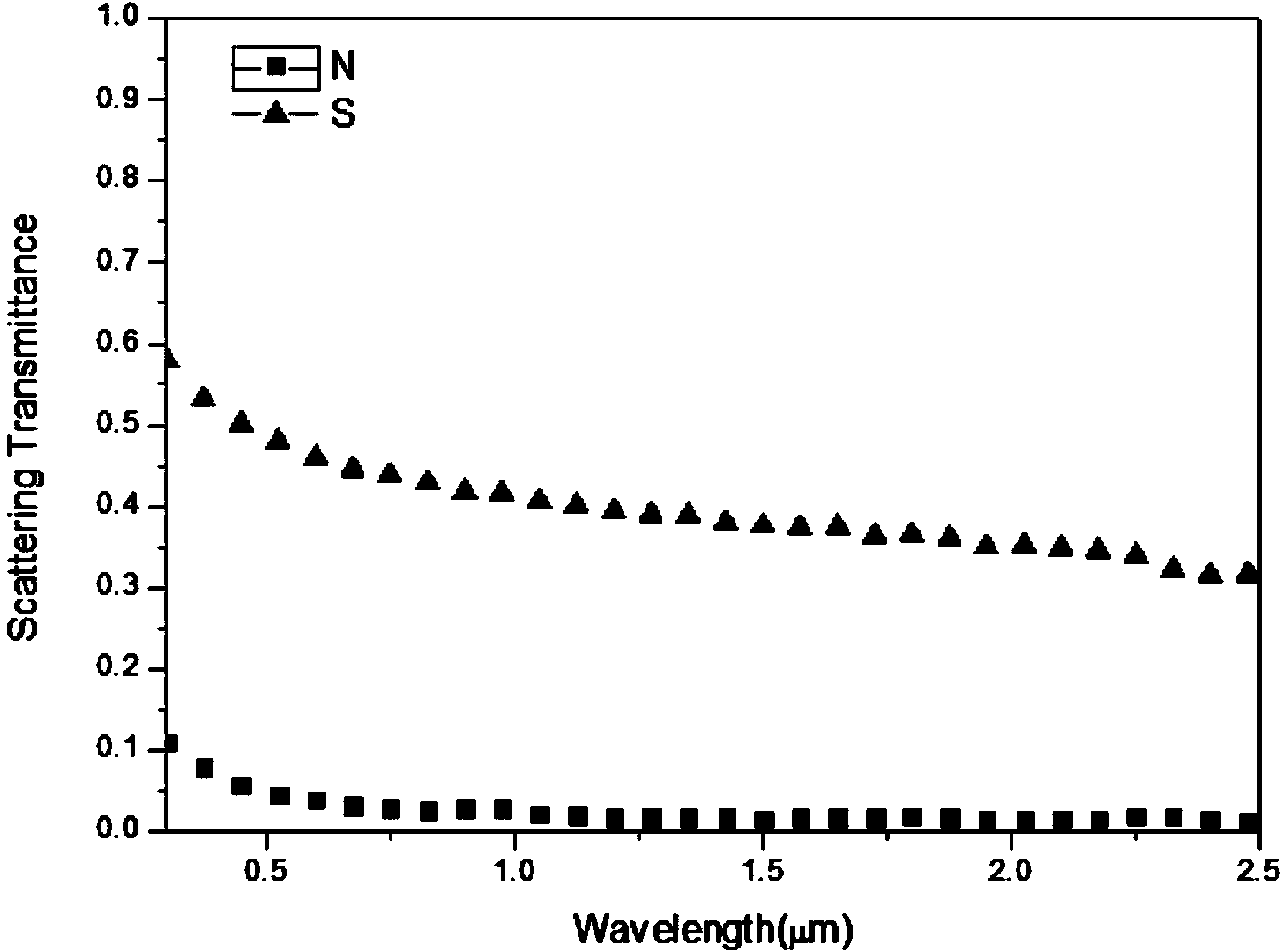

[0026] As shown in the accompanying drawings, wherein N represents the traditional agricul...

Embodiment 2

[0028] Diffuse masterbatch is prepared according to the following formula in weight ratio:

[0029] LDPE: 10 parts; LLDPE: 1 part; Magnesium oxide: 1.5 parts; Talc powder: 1 part; Magnesium stearate: 0.8 parts; Polyethylene wax: 0.2 parts.

[0030] Preparation method of agricultural film: Stir the well-proportioned masterbatch evenly, so that all the additives evenly adhere to the surface of the plastic, put it on the extruder, extrude and granulate. Using LDPE as the matrix resin, blow molding is performed according to the ratio of masterbatch: matrix resin = 1:10, and the thickness of the prepared film is 0.1mm. Before blow molding, dripping agent and anti-ultraviolet agent are added, so that the prepared agricultural film has milky white high-performance, long-life scattering agricultural film with anti-dripping and anti-aging properties while scattering sunlight.

Embodiment 3

[0032] Diffuse masterbatch is prepared according to the following formula in weight ratio:

[0033] LDPE: 9 parts; LLDPE: 2 parts; Zinc oxide: 0.6 parts; Magnesium oxide: 0.7 parts; Talc powder: 0.8 parts; Magnesium stearate: 1 part; Polyethylene wax: 0.4 parts.

[0034] Preparation method of agricultural film: Stir the well-proportioned masterbatch evenly, so that all the additives evenly adhere to the surface of the plastic, put it on the extruder, extrude and granulate. Using LDPE as the matrix resin, blow molding is carried out according to the ratio of masterbatch: matrix resin = 1:40, and the thickness of the prepared film is 0.02mm. Before blow molding, the dripping agent and anti-ultraviolet agent purchased from the market are added, so that the prepared agricultural film has milky white high-performance, long-life scattering agricultural film with anti-dripping and anti-aging properties while scattering sunlight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com