A device and method for liquid-liquid extraction and separation of aromatics in diesel oil

A technology for diesel and aromatic hydrocarbons, which is applied in the petroleum industry, refined hydrocarbon oil, and multi-stage series-connected refining process treatment. The effect of diesel quality, improved separation efficiency, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

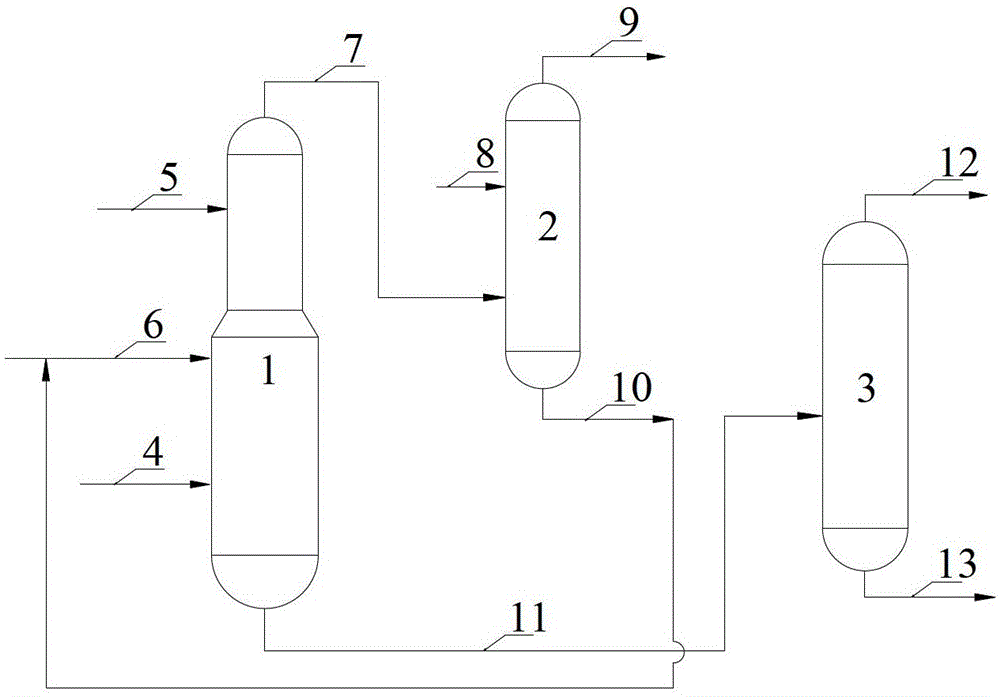

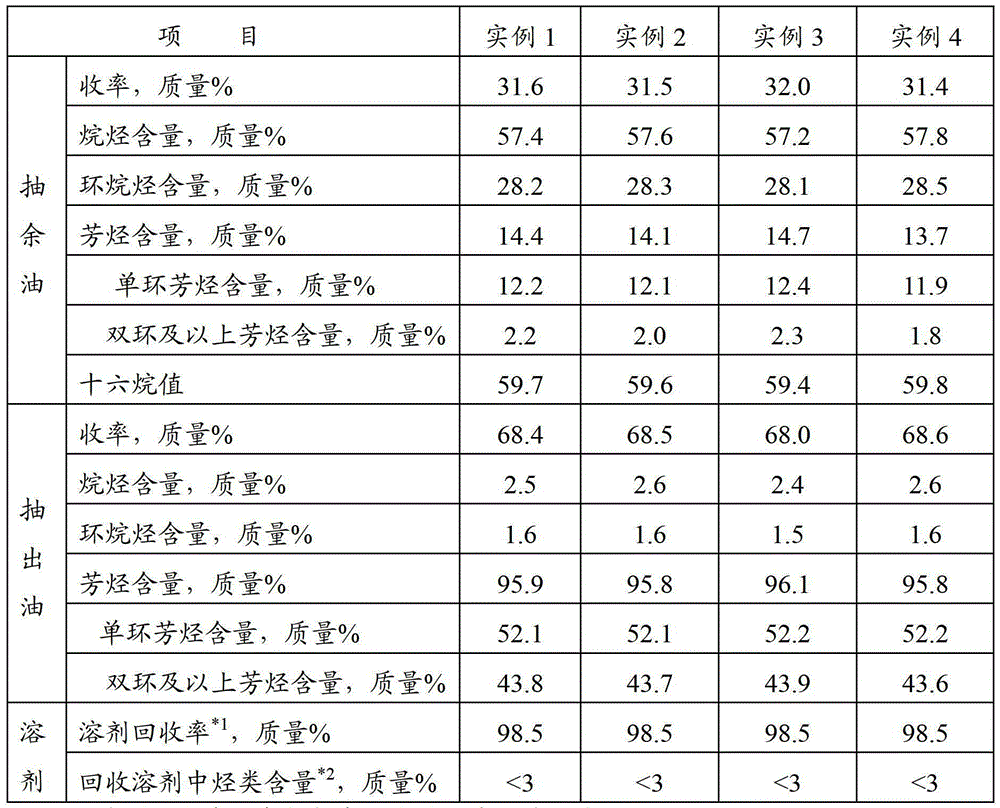

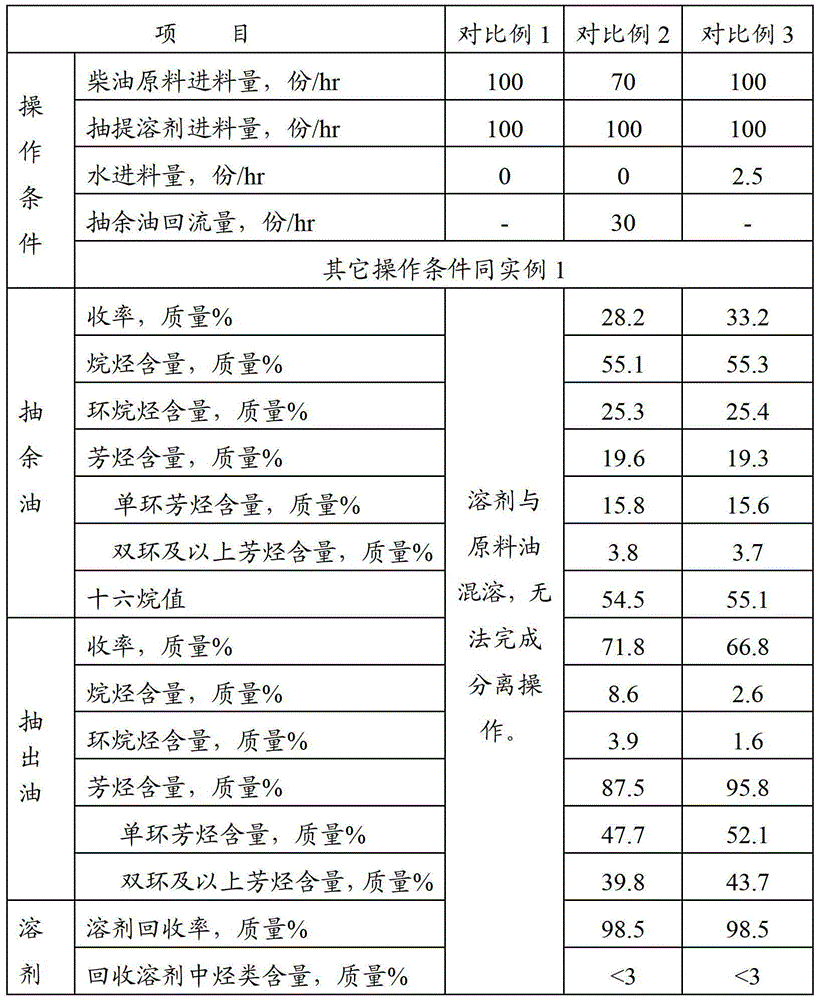

[0034] according to figure 1The process shown in Table 1 performs liquid-liquid extraction to separate the aromatics in the diesel feedstock with the properties listed in Table 1. The height of the liquid-liquid extraction tower is H, and the height of the part with a small diameter on the upper part is H. 1 . The extraction solvent is DMF (N, N-dimethylformamide), which is injected into the upper part of the liquid-liquid extraction tower. The co-solvent is water, which is injected at the top of the lower part of the tower. The distance between the co-solvent injection point and the bottom of the liquid-liquid extraction tower is The distance is H 2 . The shape and size of the liquid-liquid extraction tower, operating conditions, and the location and amount of co-solvent injection are shown in Table 2. The operating temperature of the solvent recovery tower is 110°C and the pressure is 30kPa. After the aromatics are extracted, the non-aromatics are discharged from the top ...

example 2

[0036] Carry out liquid-liquid extraction and separation of aromatics therein to the diesel oil feedstock listed in Table 1 by the method of Example 1, the difference is to change the consumption of extraction solvent, co-solvent feeding position and consumption. See Table 2 for the shape and size of the liquid-liquid extraction tower, operating conditions, injection location and dosage of co-solvent. The composition of raffinate oil and extracted oil is shown in Table 3.

example 3

[0038] Carry out liquid-liquid extraction and separation of aromatics therein to the diesel oil feedstock listed in table 1 by the method of example 1, difference is to change the diameter ratio of the upper and lower parts of the liquid-liquid extraction tower, change the extraction solvent into ethylene glycol methyl ether, and Change its dosage. See Table 2 for the shape and size of the liquid-liquid extraction tower, operating conditions, injection location and dosage of co-solvent. The composition of raffinate oil and extracted oil is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com