Superlattice Sm-Mg-Ni multiphase alloy, preparation method and application of superlattice Sm-Mg-Ni multiphase alloy as well as nickel-metal hydride battery

A nickel-metal hydride battery and superlattice technology, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve the problems of comprehensive hydrogen storage performance, low hydrogen storage capacity of base alloy, and long time consumption, etc., to achieve good activation Effects of performance and cycle life, low activity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

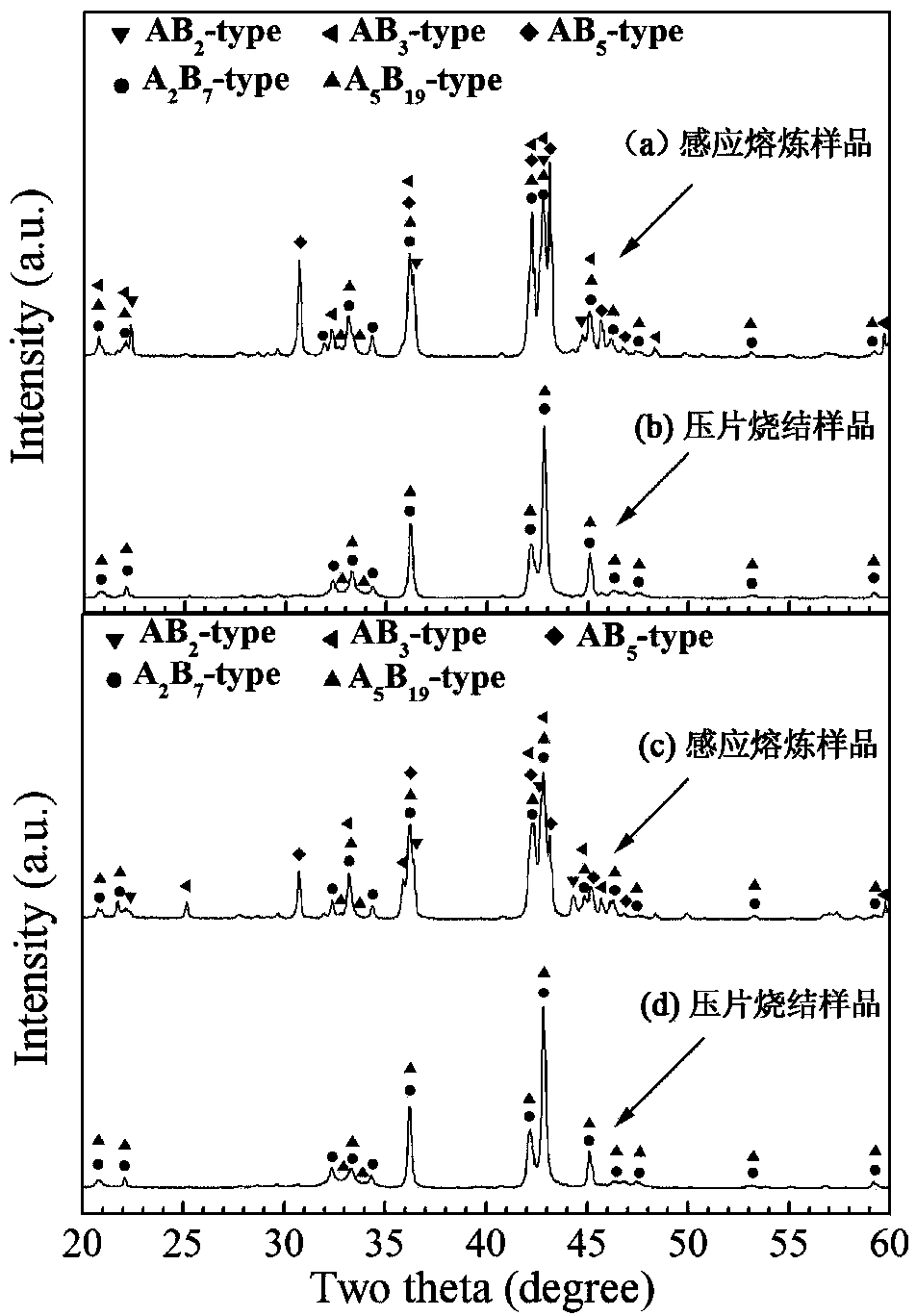

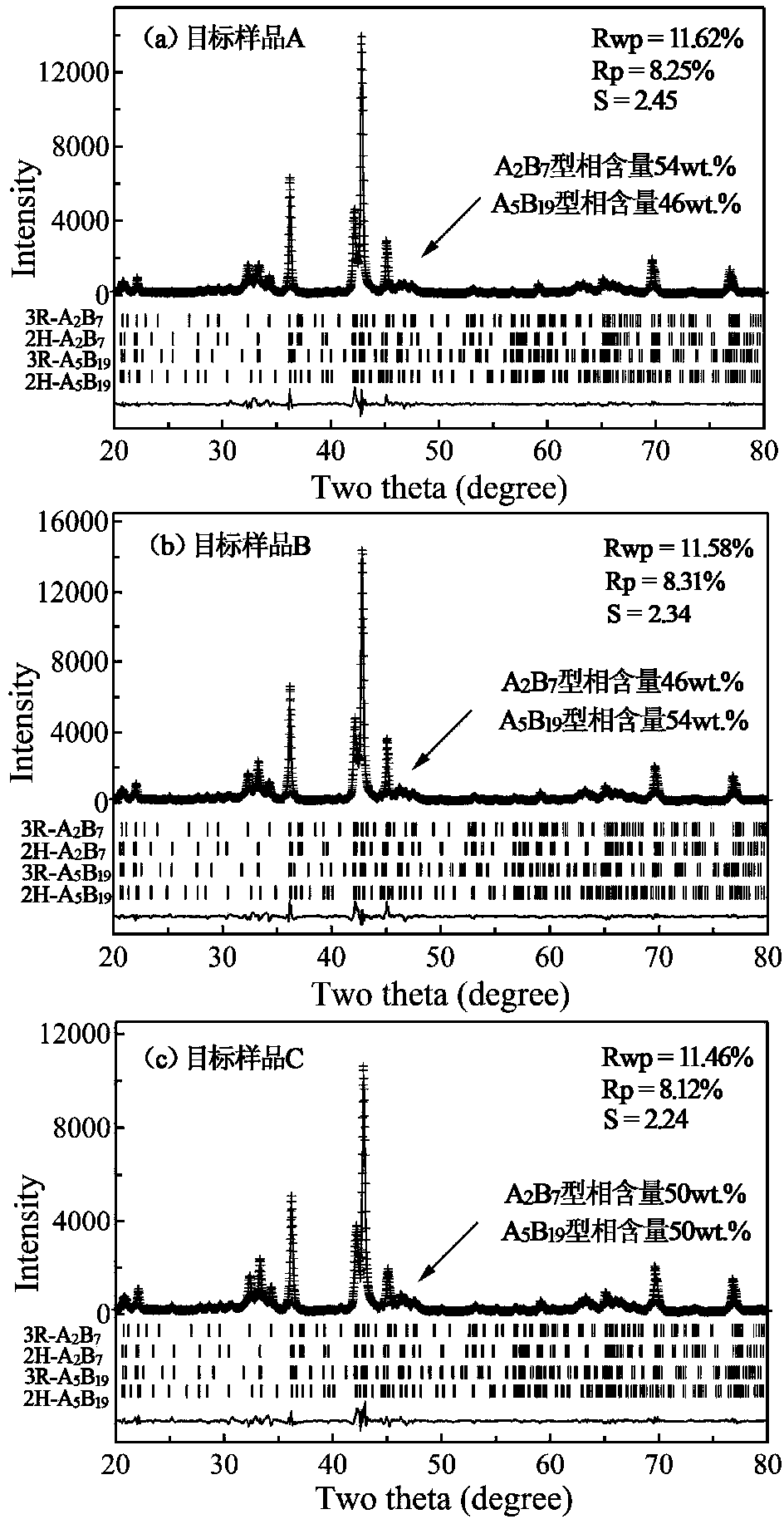

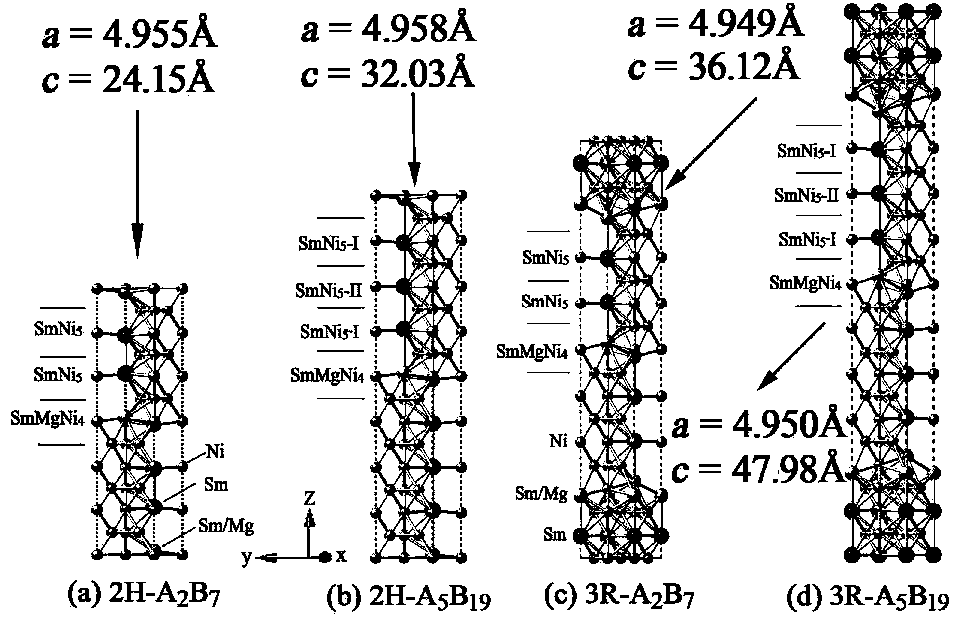

[0046] The total weight of the smelted alloy is 30 grams, according to 54wt% Sm 3 MgNi 14 +46wt%Sm 4 MgNi 19 The target composition ratios were weighed Sm flakes (purity 99%, 3 wt% more burn loss for Sm), Mg flakes (99.5% purity, 10 wt% more burn loss for Mg) and Ni flakes (99% purity ). Put the weighed Sm, Mg and Ni sheets into a copper crucible and induction melting at 18KW power to obtain a Sm–Mg–Ni ternary alloy. The alloy phase composition is as follows: figure 1 As shown in (a) in the alloy, it is clear that AB is present in the alloy 2 , AB 3 , A 2 B 7 , A 5 B 19 and AB 5 types, etc. Use a grinder to remove the oxide scale on the surface of the smelted alloy, and then grind it into a 300-mesh alloy powder in a glove box filled with inert gas protection. Tablets were pressed under an argon atmosphere. Then, the green sample was sealed in a stainless steel container filled with inert gas and annealed in a common vacuum annealing furnace for 2 hours at a tempe...

Embodiment 2

[0048] The total weight of the smelted alloy is 30 grams, according to 46wt% Sm 3 MgNi 14 +54wt%Sm 4 MgNi 19 The target composition ratios were weighed Sm flakes (purity 99%, 3 wt% more burn loss for Sm), Mg flakes (99.5% purity, 10 wt% more burn loss for Mg) and Ni flakes (99% purity ). Put the weighed Sm, Mg and Ni sheets into a copper crucible and induction melting at 18KW power to obtain a Sm–Mg–Ni ternary alloy. The alloy phase composition is as follows: figure 1 As shown in (c) in the alloy, it is clear that AB is present in the alloy 2 , AB 3 , A 2 B 7 , A 5 B 19 and AB 5 types, etc. The oxide scale on the surface of the smelted alloy was removed with a grinder, and then ground into a 260-mesh alloy powder in a glove box filled with inert gas protection. Then, the green sample was sealed in a stainless steel container filled with inert gas and annealed in a common vacuum annealing furnace for 4 hours at a temperature of 850°C. The phase composition of the an...

Embodiment 3

[0050] Same as Example 1, the difference is that according to 50wt% Sm 3 MgNi 14 +50wt%Sm 4 MgNi 19 The target composition ratio was weighed respectively for Sm flakes (purity 99.6%, with 5 wt% more burn loss added to Sm), Mg flakes (purity of 99%, 16 wt% more burn loss added to Mg, the specific burn loss is and adopts The crucible, the induction furnace are related to the preparation parameters, and this burning loss can be calculated by the equipment used by those skilled in the art, which will not be repeated here) and Ni sheets; the as-cast alloy is ground into 200 mesh alloy powder; green annealing 3 hours, the annealing temperature is 810℃, such as figure 2 (c), after annealing, only 50 wt% Sm was obtained. 3 MgNi 14 and 50wt% Sm 4 MgNi 19 Phase superlattice hydrogen storage alloy (it should be noted that in this application document, since the unavoidable impurity has little influence on the experimental results, it is not considered as an object); Image 6 (a)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com