Short-bar-shaped nano-zinc oxide/graphene compound and preparation method thereof

A nano-zinc oxide and composite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as not applicable to practical applications, complicated operation, and reduced interaction, and achieve excellent gas Sensitivity, good application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

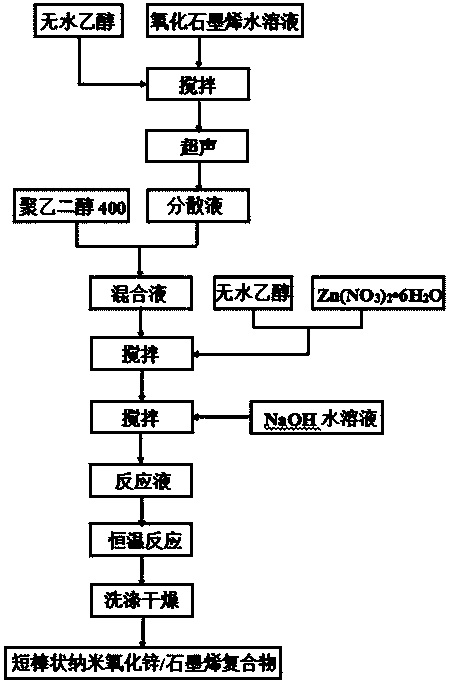

[0035] Combine figure 1 , The present invention is a method for preparing short rod-shaped nano-zinc oxide / graphene composite. The method uses the surfactant polyethylene glycol 400 to uniformly load nano-zinc oxide on the surface of the graphene sheet, and specifically includes the following steps :

[0036] Step 1: Disperse the graphene oxide aqueous solution in absolute ethanol, and then perform ultrasonic treatment to obtain a uniform dispersion; the concentration of the graphene oxide aqueous solution is 5-30mg / g, and the ultrasonic time is 10-120min;

[0037] Step 2: Add the surfactant polyethylene glycol 400 to the dispersion obtained in step 1 to obtain a mixed solution; the volume ratio of polyethylene glycol 400 to the absolute ethanol in the system is 1:70 to 1:10;

[0038] Step 3: Add Zn(NO 3 ) 2 ·6H 2 O is dissolved in absolute ethanol, and then added to the mixed solution of step two; the graphene oxide aqueous solution in step one and the Zn(NO 3 ) 2 ·6H 2 The mass rat...

Embodiment 1

[0043] Step 1: Disperse 0.7550 g of graphene oxide aqueous solution (20 mg / g) in 60 mL of absolute ethanol, stir for 20-60 minutes, and then perform ultrasonic treatment for 30 minutes to obtain a uniform dispersion;

[0044] Step 2: Add 2 mL of polyethylene glycol 400 to the dispersion obtained in step 1, and stir for 20-60 minutes to obtain a mixed solution;

[0045] Step 3: Add 1.7849gZn(NO 3 ) 2 ·6H 2 O was dissolved in 10 mL of absolute ethanol, stirred for 20-60 minutes, then added to the mixed solution of step 2, and stirred for 20-60 minutes;

[0046] Step 4: Add 2.5mol / L NaOH aqueous solution to step 3, adjust the pH to 9-10, and then react at a constant temperature in a closed reaction kettle, the reaction temperature is 180°C, and the reaction time is 12h; after the reaction, the product is washed, After drying, a short rod-shaped nano-zinc oxide / graphene composite is obtained.

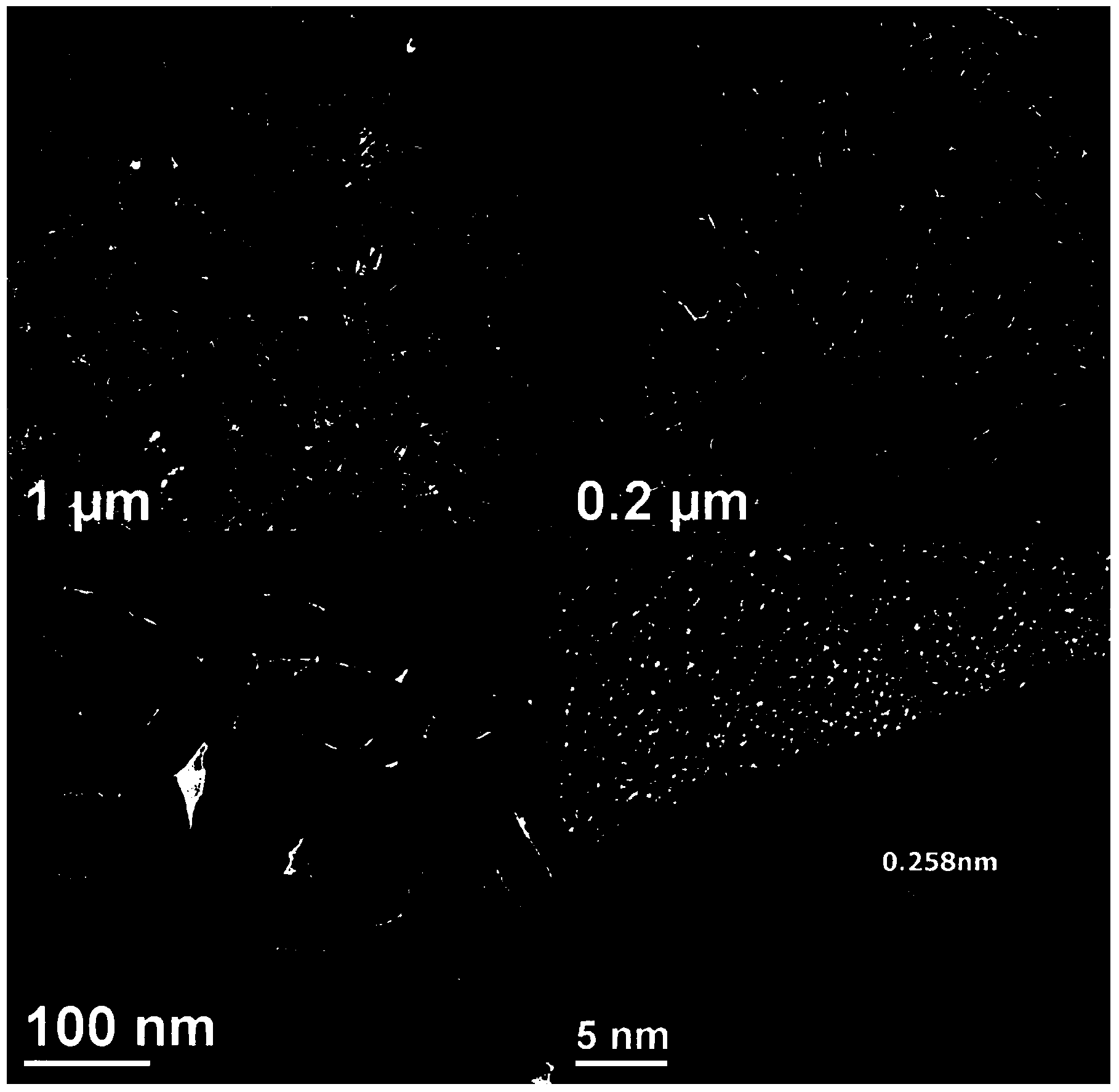

[0047] The photos of the resulting product are as figure 2 As shown, the short rod-shaped nano...

Embodiment 2

[0049] Step 1: Disperse 0.8221 g of graphene oxide aqueous solution (10 mg / g) in 60 mL of absolute ethanol, stir for 20-60 minutes, and then perform ultrasonic treatment for 30 minutes to obtain a uniform dispersion;

[0050] Step 2: Add 2 mL of polyethylene glycol 400 to the dispersion obtained in step 1, and stir for 20-60 minutes to obtain a mixed solution;

[0051] Step 3: Add 2.9749gZn(NO 3 ) 2 ·6H 2 O was dissolved in 10 mL of absolute ethanol, stirred for 20-60 minutes, then added to the mixed solution of step 2, and stirred for 20-60 minutes;

[0052] Step 4: Add 5mol / L NaOH aqueous solution to step 3, adjust the pH to 9-10, then react at a constant temperature in a closed reaction kettle, the reaction temperature is 180℃, and the reaction time is 24h; after the reaction, the product is washed and dried A short rod-shaped nano-zinc oxide / graphene composite is obtained.

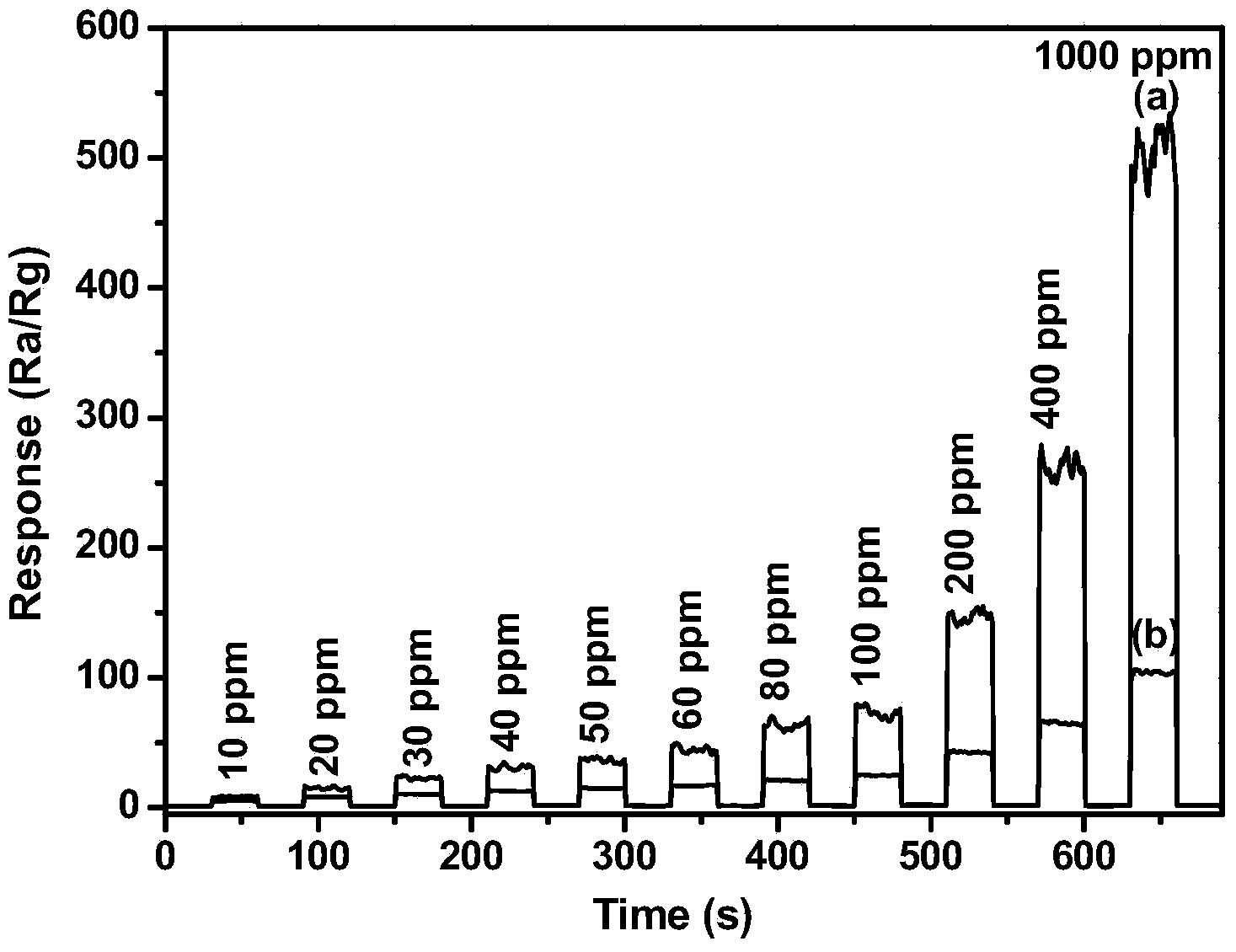

[0053] Calculated from the gas sensitivity test, the sensitivity of the short rod-shaped nano-zinc oxide / gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com