Optical fiber mode separator

A mode splitter and optical fiber technology, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problems of narrow working bandwidth and difficult to achieve broadband matching, and achieve the effects of suppressing interference, effectively separating, and increasing the difference in coupling length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

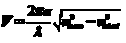

[0027] Preferred embodiments of the present invention are described below in conjunction with the accompanying drawings. Such as figure 1 As shown, this embodiment realizes LP 02 Die and LP 01 Die, LP 11 Separation between modules. The fiber matrix material 1 is pure silica, the radius of the three cores is 6.15 μm, and the refractive index difference between the core and the cladding is 0.012. The distance between the centers of adjacent cores is 22 μm. Light is input from the first core 2, LP 02 One mode is output from the third core 4 and the other modes are output from the first core 2 . Its coupling length curve is as image 3 shown. Visible, LP 02 The mode coupling length is much smaller than that of the other two modes. Take the fiber length as 33.5 mm. The energy of different modes output by the third core 4 is as follows: Figure 4 shown. Visible, in the wavelength range of 1.48-1.515μm, LP 02 The output power of the mode is greater than -1 dB, while th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com