Manufacturing method of copper nano wire network wrapped by graphene carbon film

A copper nanowire, graphene carbon technology, applied in carbon silicon compound conductors, cable/conductor manufacturing, metal/alloy conductors and other directions, can solve the problem of high resistance of Cu nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

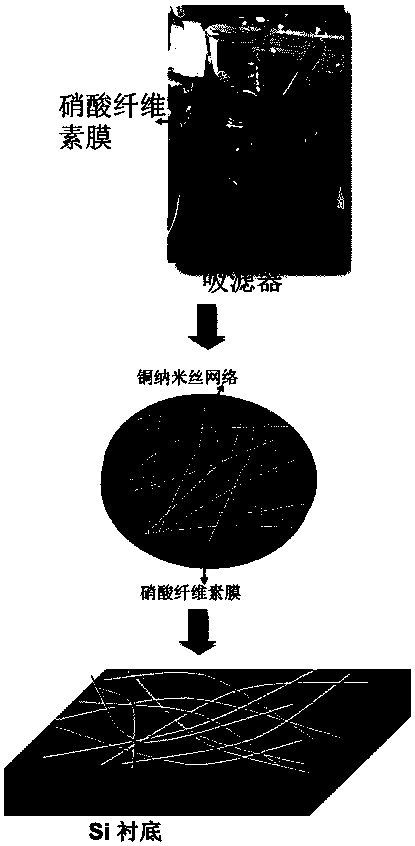

[0025] Firstly, Cu nanowire thin film electrodes were fabricated by suction filtration imprinting technique.

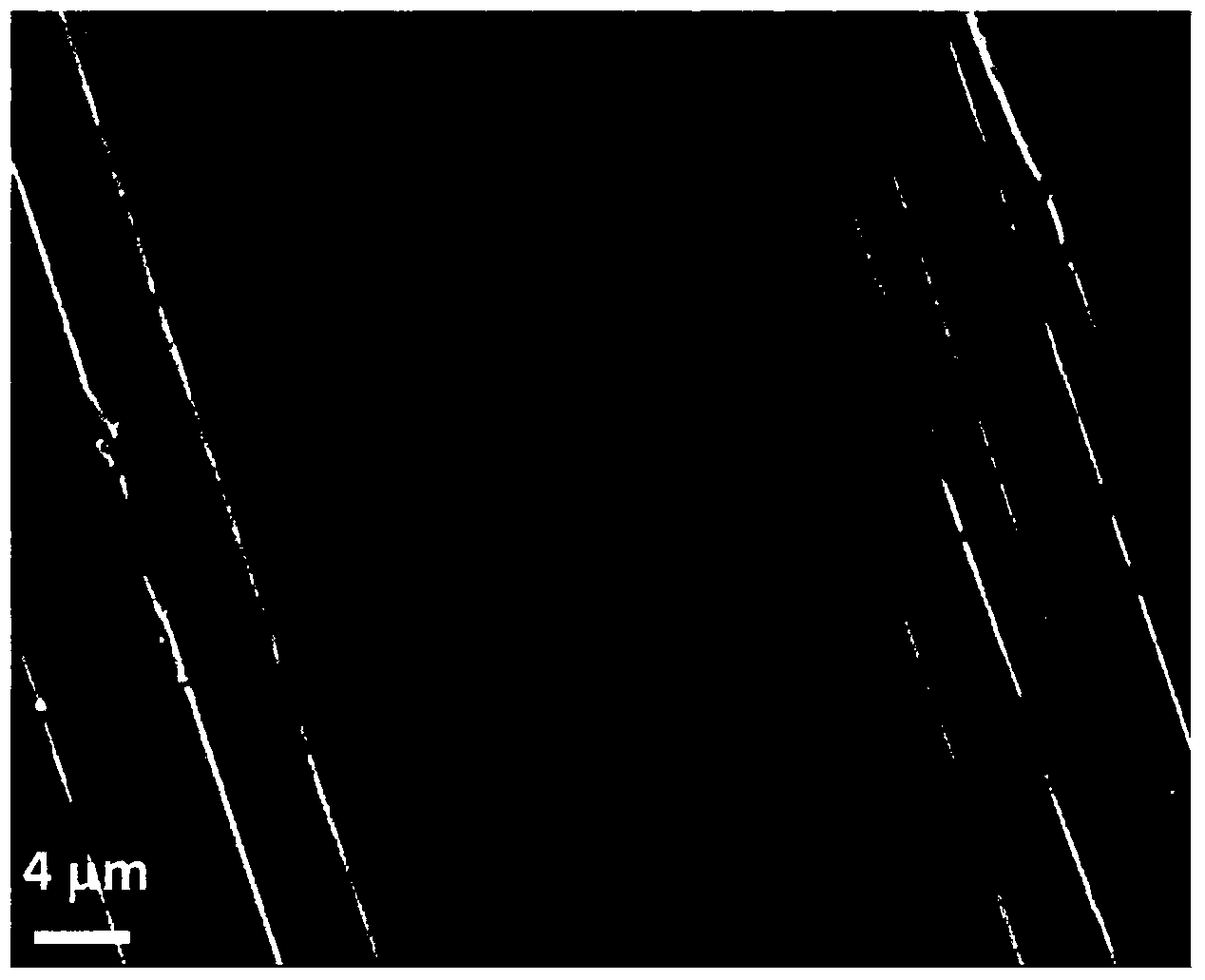

[0026] 1) Take 50mg of Cu nanowires, disperse them in 10ml of n-hexane after ultrasonic oscillation for 20min, take 0.5ml from it, dilute to 30ml with n-hexane, and ultrasonically vibrate for 20min. Then measure 10ml of the solution and add it dropwise to the container on the nitrocellulose membrane. Using a vacuum filter (such as figure 1 As shown in the first step), turn on the vacuum mechanical pump for 3s, and filter the n-hexane solvent through the nitrocellulose membrane to form a uniform Cu nanowire film with a certain humidity. The main point of this technology is that the concentration and volume of the solution must be precisely controlled, and the vacuum filtration time (this time is proportional to the volume of the solution) must be accurately controlled. After the filtration, the Cu nanowire film still maintains a certain humidity, so that the subsequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com