Agent for imparting fluorescence to ceramic

A technology of imparting agents and fluorescence, applied in the direction of luminescent materials, dental preparations, chemical instruments and methods, etc., can solve problems such as productivity deterioration and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

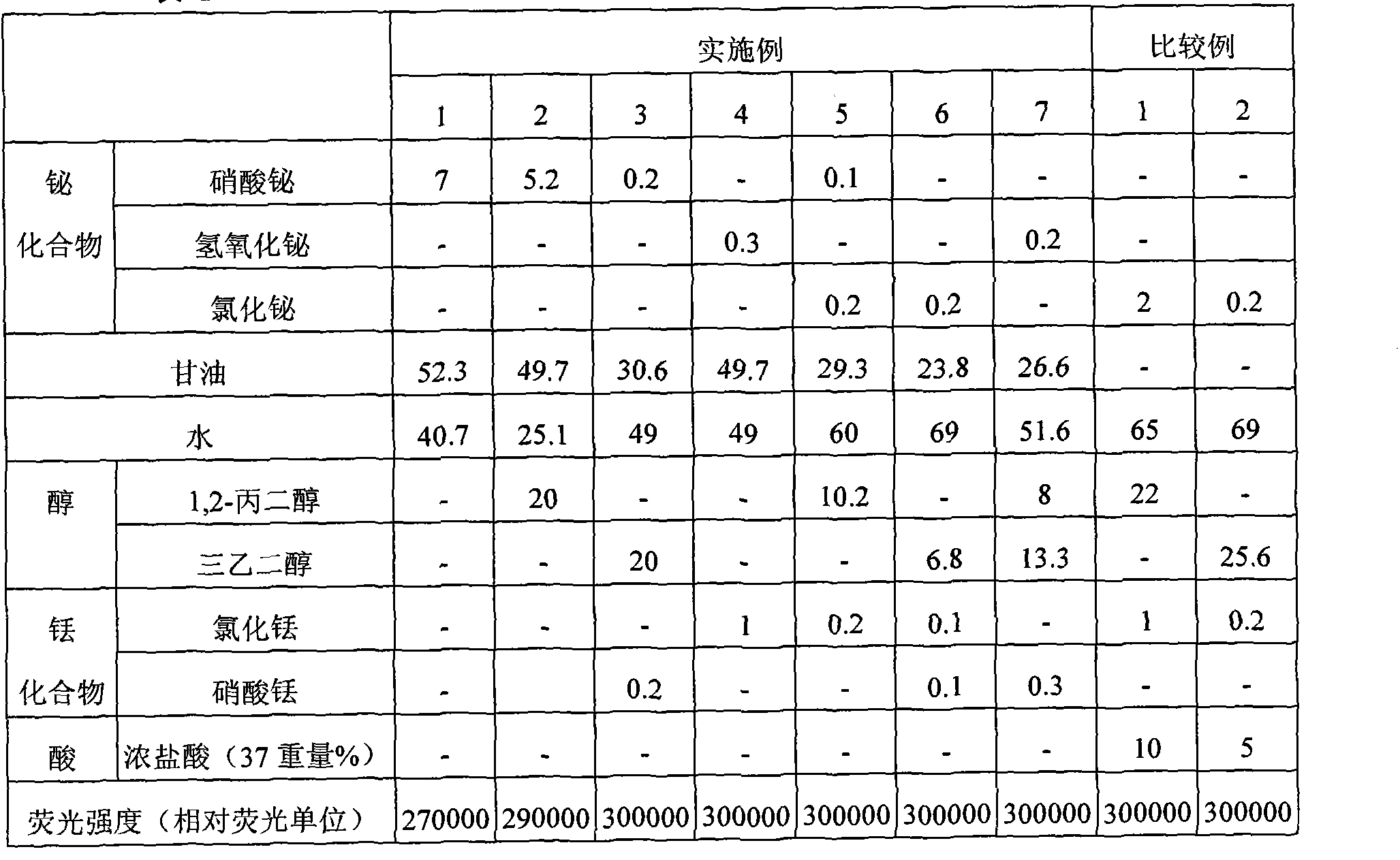

[0022] 52.3 g of glycerin (manufactured by Wako Pure Chemical Industries, Ltd.) was added to 40.7 g of water, mixed and stirred for 30 minutes. This aqueous glycerin solution was mixed with 7 g of bismuth nitrate (manufactured by Wako Pure Chemical Industries, Ltd.) and further stirred for 120 minutes to obtain a fluorescence imparting agent for ceramics (Example 1). Based on the compositions in Table 1, the fluorescence imparting agents for ceramics according to the present invention (Examples 2 to 7) and the fluorescence imparting agents for ceramics (Comparative Examples 1 and 2) produced by a conventional production method using an acid solution were prepared according to the same method As a comparative example. In the present example and the comparative example, the fluorescence imparting agent for ceramics was prepared in the g unit of the numerical value in Table 1, however, in the actual production according to the prior art, for example, in order to manufacture 100 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com