Method for treating titanium dioxide wastewater through sulfuric acid process

A technology of titanium dioxide wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as high water content, large land occupation, and difficulty in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

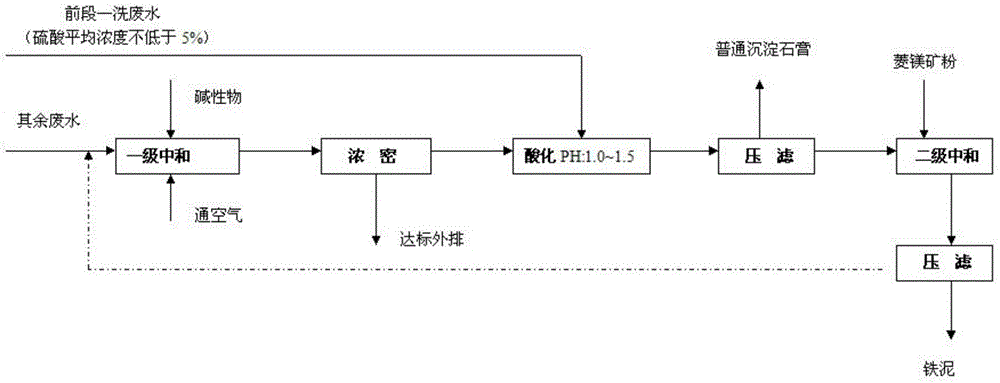

[0034] Embodiment 1: (1) The first-stage first-wash wastewater whose sulfuric acid concentration in the metatitanic acid first-wash section is not less than 5%, that is, the first-wash wastewater corresponding to the first 2h part of the first wash, is separated separately and sent to the acidification tank, This part of the H in the wastewater 2 SO 4 The average concentration is 10.50%, and the content of Fe is 1.77%; (2) Collect the acid wastewater produced in the second stage of the metatitanic acid washing section and other sections to the wastewater homogenization tank for homogenization, and measure the homogenization H in the waste water 2 SO 4 The concentration is 1.8%, the content of Fe is 0.15%, neutralized with calcium carbide slag or lime to pH: 7, and oxidized by air for 1 hour to obtain neutralized slurry a; (3) send neutralized slurry a into The dense pool settles for 1 hour, and the supernatant is discharged after reaching the standard, and the dense slurry ...

Embodiment 2

[0035] Embodiment 2: (1) Separate the wastewater from the first washing in the metatitanic acid first washing section with a sulfuric acid concentration of not less than 7%, that is, the first washing wastewater corresponding to the part 1.5h before the first washing, and send it to the acidification tank , this part of a washing wastewater H 2 SO 4 The average concentration is 12.50%, and the content of Fe is 1.9%; (2) Collect the acid waste water produced in the second stage of the metatitanic acid washing process and other processes in the waste water homogenization tank for homogenization, and measure the homogenization H in the waste water 2 SO 4 The concentration is 1.85%, the content of Fe is 0.16%, neutralize with calcium carbide slag or lime to pH: 8, and pass through the air to oxidize for 2 hours to obtain the neutralized slurry a; (3) send the neutralized slurry a into The dense pool settles for 1 hour, and the supernatant is discharged after reaching the standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com