How to Make Onion Wine

A wine and onion technology, which is applied in the field of wine making, can solve the problems of no scale sales, heavy onion smell, and difficulty in promotion, and achieve the effects of improving nutritional value and health care, reducing onion odor, and being easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

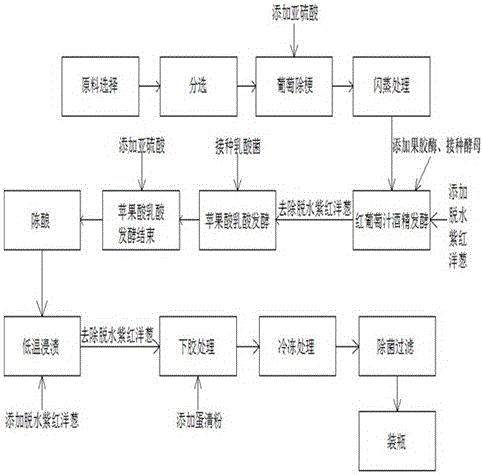

Method used

Image

Examples

Embodiment 1

[0048] In the third step of the above method, 0.4L / ton of sulfurous acid (sulfur dioxide content is 6%) is added in a balanced manner online to the destemmed grapes; in the fourth step, the grapes coming out of the buffer tank enter a sleeve heater, The grapes are quickly heated to 80°C, and the heated grapes enter the negative pressure tank; in the fifth step, 200g / m of high-quality Saccharomyces cerevisiae is inoculated 3 ; In the seventh step, after confirming the completion of malolactic fermentation, add sulfurous acid (sulfur dioxide content is 6%) 0.7L / m 3 ;In the tenth step, add 50g / m of egg white powder to the onion wine 3 .

Embodiment 2

[0050] In the third step of the above method, 0.2L / ton of sulfurous acid (sulfur dioxide content is 6%) is added in a balanced manner online to the destemmed grapes; in the fourth step, the grapes coming out of the buffer tank enter a sleeve heater, The grapes are quickly heated to 85°C, and the heated grapes enter the negative pressure tank; in the fifth step, 150g / m of high-quality Saccharomyces cerevisiae is inoculated 3 ; In the seventh step, after confirming the completion of malolactic fermentation, add sulfurous acid (sulfur dioxide content is 6%) 0.65L / m 3 ;In the tenth step, add egg white powder 60g / m to the onion wine 3 .

Embodiment 3

[0052] In the third step of the above method, 0.3L / ton of sulfurous acid (sulfur dioxide content is 6%) is added on-line to the destemmed grapes; in the fourth step, the grapes coming out of the buffer tank enter a sleeve heater, The grapes are quickly heated to 80°C, and the heated grapes enter the negative pressure tank; in the fifth step, 180g / m of high-quality Saccharomyces cerevisiae is inoculated 3 ; In the seventh step, after confirming the completion of malolactic fermentation, add sulfurous acid (sulfur dioxide content is 6%) 0.75L / m 3 ;In the tenth step, add egg white powder 30g / m to the onion wine 3 .

[0053] All of the above three embodiments can brew onion wine with little onion odor, good taste and high content of onion active ingredients.

[0054] The present invention adopts flash steaming treatment of raw materials, mixed alcoholic fermentation (alcoholic fermentation of red grape juice, malolactic fermentation) supplemented by low-temperature extraction pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com