Process for recycling waste heat of slag flushing water vapor and dispersing fog and equipment adopted in same

A technology of waste heat recovery and water vapor, applied in lighting and heating equipment, steam/steam condenser, etc., to achieve obvious effects, outstanding effects, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

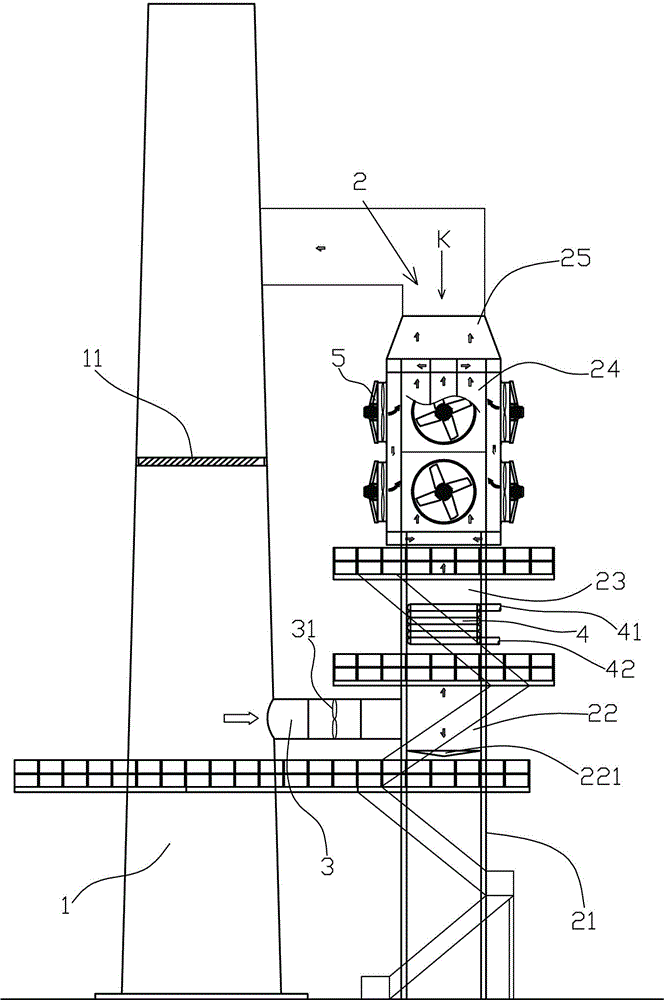

[0032] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

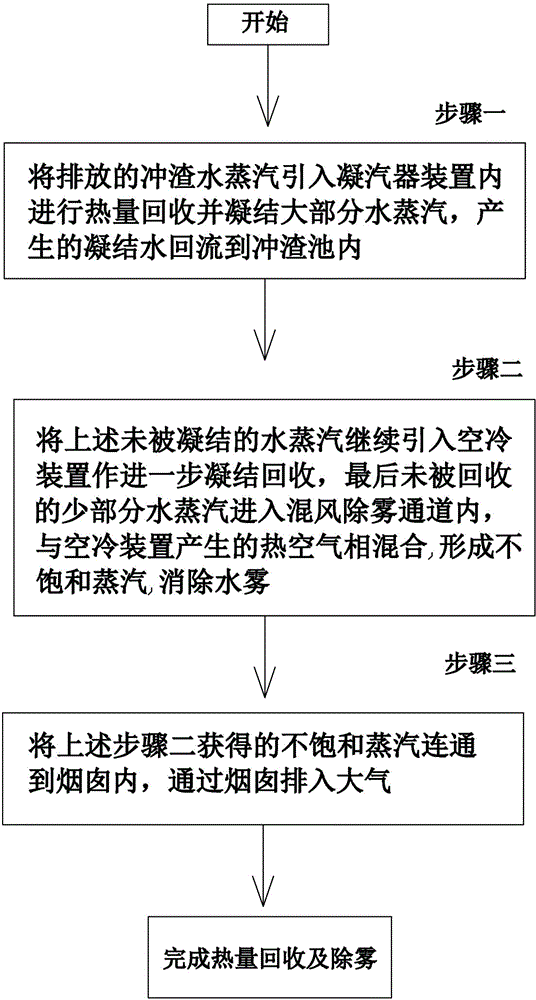

[0033] like figure 1 As shown in the figure, a process for recovering the residual heat of slag flushing water vapor and eliminating fog includes the following specific steps:

[0034] 1) Use the induced draft equipment to introduce the discharged slag-washing water vapor into a waste heat recovery and mist removal tower for waste heat recovery and elimination of water mist, first use the condenser device in the equipment to condense part of the water vapor and recover the water vapor At the same time, the generated condensed water is returned to the slag washing tank (step 1).

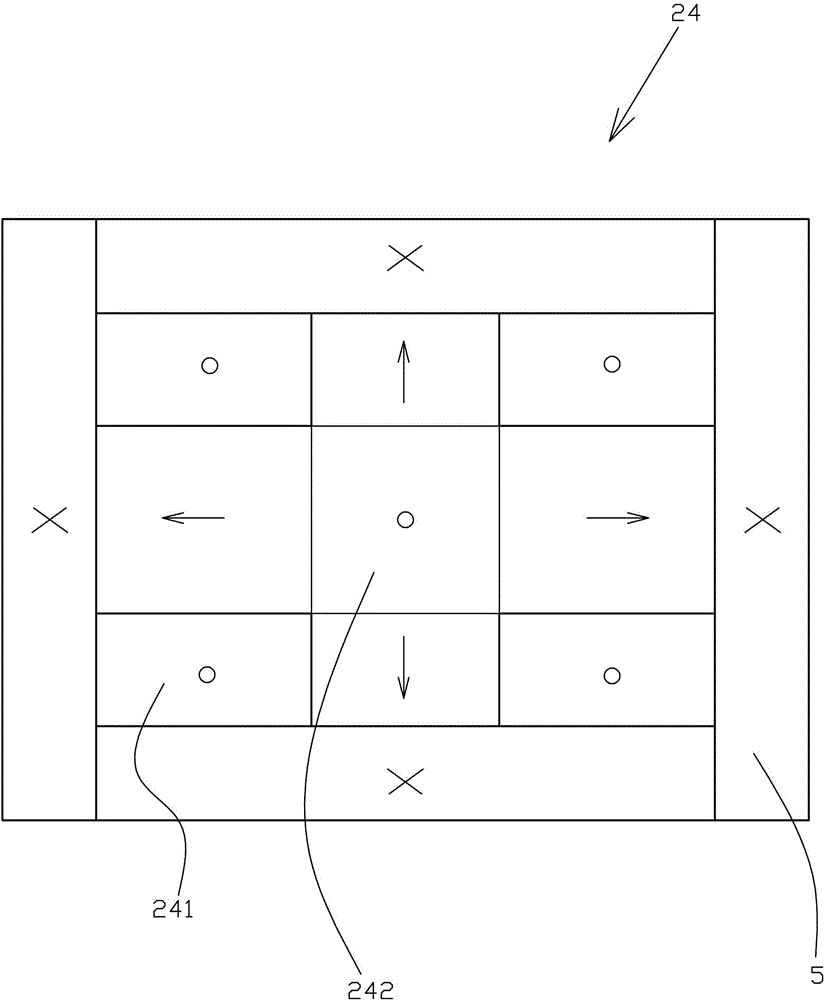

[0035] 2) The above-mentioned uncondensed water vapor ascends from the channel in the middle of the waste heat recovery and mist removal tower, and enters the air cooling device for further condensing the water vapor. The air cooling device will generate hot air duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com