Secondary lead smelting method

A secondary lead smelting and lead paste technology, which is applied in the field of secondary lead smelting, can solve the problems of high moisture content in desulfurized lead paste, long smelting cycle, high comprehensive energy consumption, etc., and achieve waste reuse, high direct recovery rate, comprehensive The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

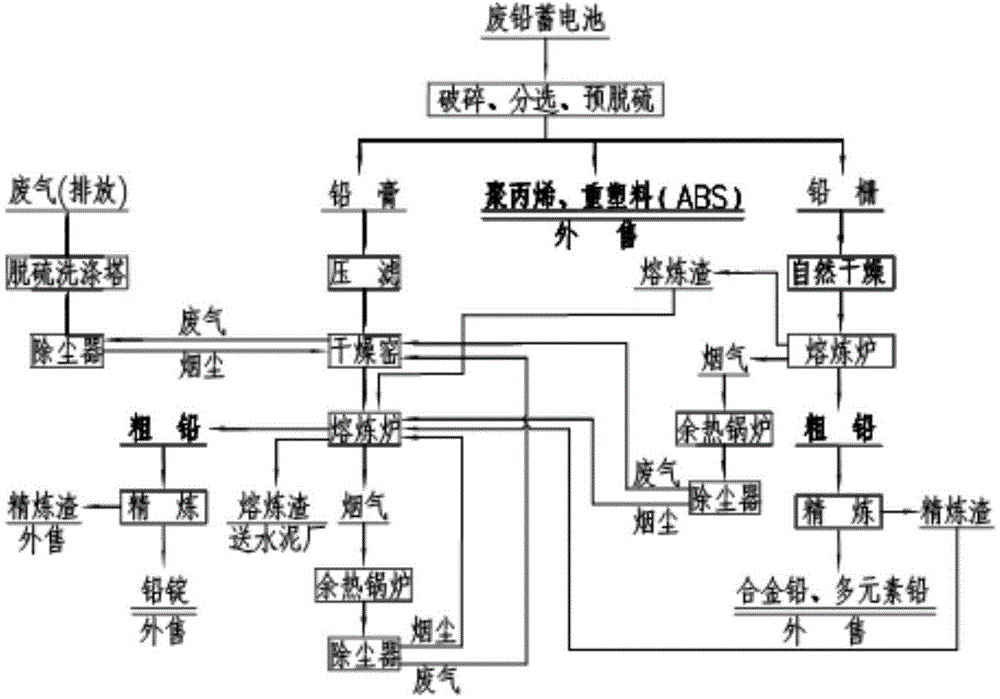

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the secondary lead smelting method of the present invention includes crushing waste lead storage batteries, pre-desulfurizing, and sorting to obtain lead paste, lead grids and plastics, wherein the plastics are mainly polypropylene, heavy plastics and ABS.

[0018] The lead paste is dried in a drying kiln and then melted in a lead paste smelting furnace, and the generated flue gas is processed to obtain waste gas, which is returned to the drying kiln at the same time.

[0019] Among them, the main component of lead paste is lead carbonate, which contains about 20% water. If it is directly smelted, it needs to consume part of the fuel to remove the water therein. In the present invention, the lead paste can be press-filtered first, and then enter the drying kiln for drying. The high-temperature flue gas of abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com