Cyclone separator of circulating fluidized bed boiler with double eccentric central cylinders

A technology of cyclone separator and circulating fluidized bed, which is applied in the direction of fluidized bed combustion equipment, fuel burned in a molten state, lighting and heating equipment, etc., and can solve the problem of insufficient circulating ash, high carbon content in fly ash, and affecting boilers Operation and other issues, to achieve the effect of improving separation efficiency, high separation efficiency, and optimizing boiler operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

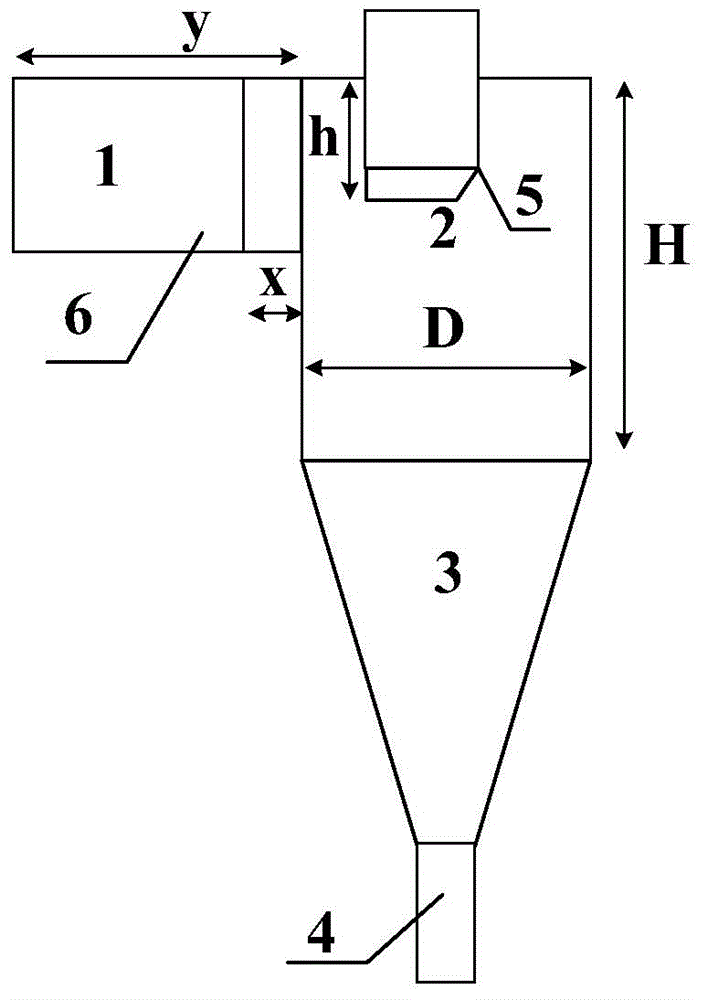

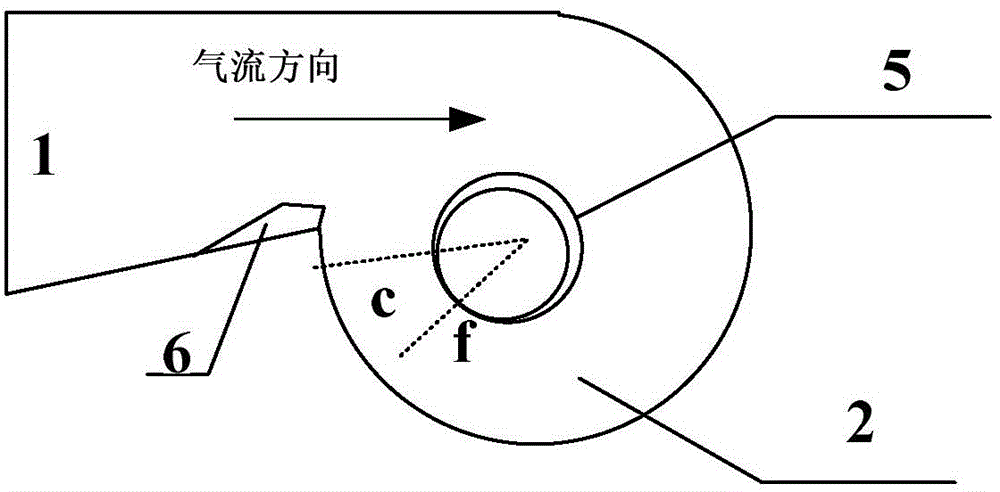

[0049] A new 130t / h circulating fluidized bed boiler, see Figure 1 to Figure 6 , the two cyclone separators of the boiler are equipped with double eccentric central tubes. The separator cylinder 2 is respectively connected with the inlet flue 1 and the separator cone 3, the separator riser 4 is arranged at the lower part of the separator cone 3, and the double eccentric central cylinder 5 is inserted into the separator cylinder 2 from the upper part.

[0050] The speed of the flue gas at the flue gas end speed increasing port 6 of the inlet flue 1 can reach 25m / s, and the distance x between the entrance of the flue gas end speed increasing port 6 close to the separator cylinder 2 is 0.1 times the length y of the inlet flue 1 .

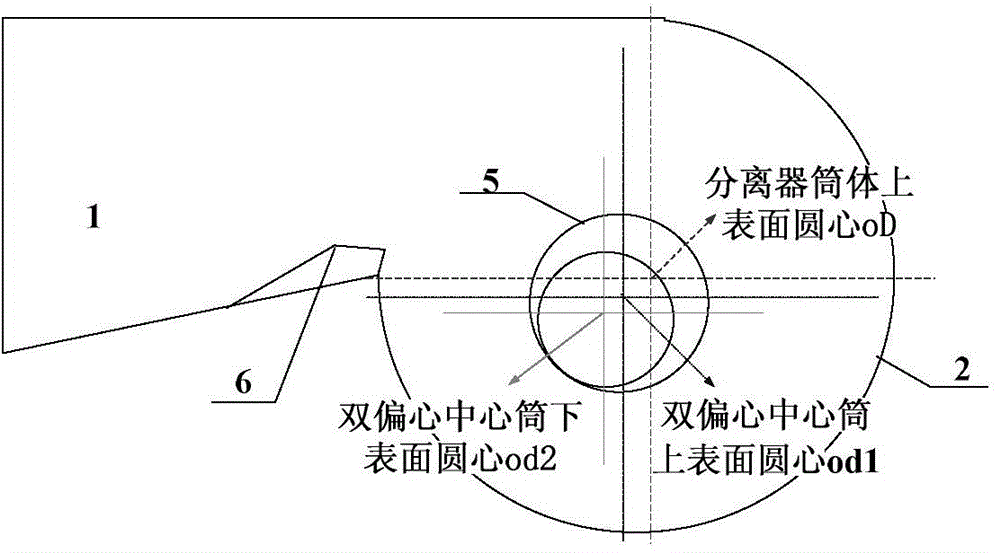

[0051] In order to improve the separation efficiency, there is a distance difference e1 between the upper surface circle center od1 of the double eccentric central cylinder 5 and the upper surface circle center oD of the separator cylinder body 2, wh...

Embodiment 2

[0054] A 240t / h circulating fluidized bed boiler in service, see Figure 1 to Figure 6 , The central tube of the two cyclone separators of the boiler adopts a conventional design. During operation, the load capacity is insufficient, the boiler output is generally only 75%, the ash concentration in the furnace is low, the pressure difference in the suspension section is only 800Pa, and the bed temperature cannot be effectively adjusted. The bed temperature in daily operation exceeds 980°C, SO 2 Emission concentration 600mg / m 3 , NO X Emission concentration 400mg / m 3 , the calcium-sulfur molar ratio of limestone is as high as 5-6, the efficiency of the separator is low, and the effective circulation of materials cannot be realized. The measured median particle size of boiler fly ash is 90 μm.

[0055] Replace the original central cylinder of the boiler with a double eccentric central cylinder. There is a distance difference e1 between the upper surface circle center od1 of th...

Embodiment 3

[0059] A new 1000t / h circulating fluidized bed boiler, see figure 1 ~ Figure 5 and Figure 7 , the three cyclone separators of the boiler are arranged on both sides of the furnace, and the central cylinder of the cyclone separator adopts a double eccentric central cylinder 5.

[0060] The inlet flue 1 is equipped with a flue gas end speed increasing port 6, and the speed of the flue gas at the flue gas end speed increasing port 6 can reach 30m / s.

[0061] There is a distance difference e1 between the upper surface circle center od1 of the double eccentric center cylinder 5 of the three separators and the upper surface circle center oD of the separator cylinder body 2. There is a distance difference e2 of 100mm between them.

[0062] The overall resistance of the cyclone separator is 1.4kPa, and the separation efficiency is 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com