Preparation method for electron back scattered diffraction test sample of zirconium oxide thermal barrier coating

A technology of electron backscattering and thermal barrier coating, applied in the preparation of test samples, etc., can solve problems such as unfavorable electron microscopy, sample crack growth, coating peeling, etc., to achieve reliable experimental results, small sample damage, No effect of abrasive contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

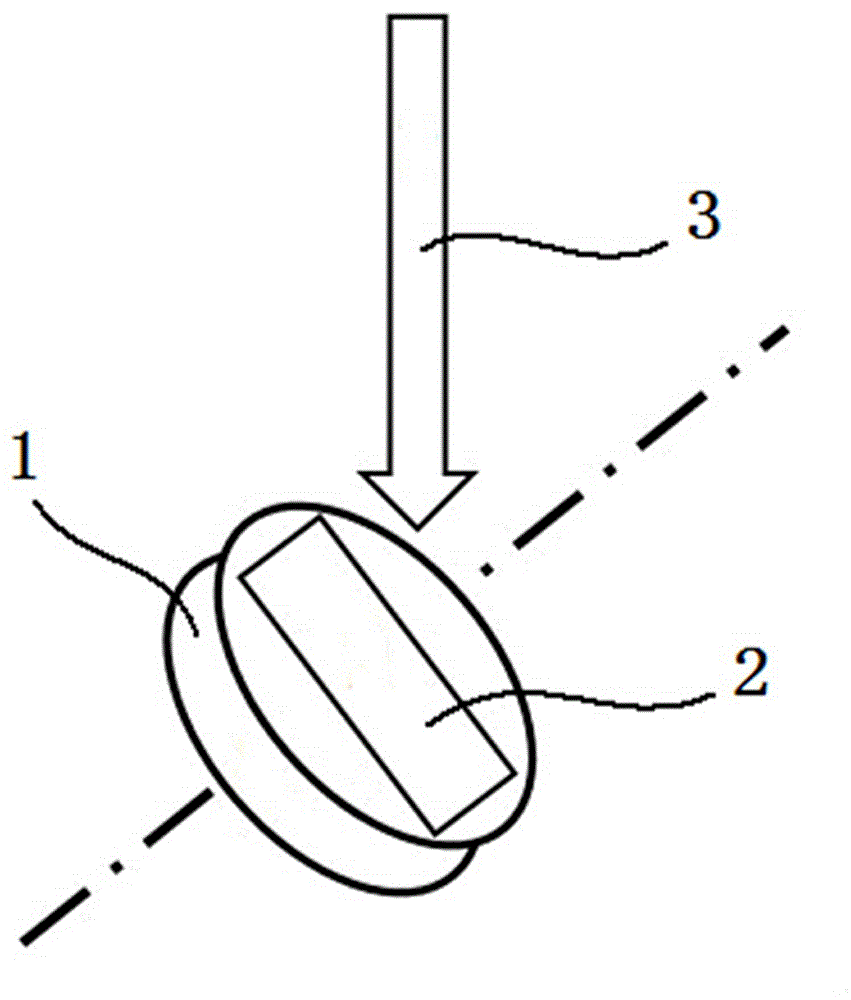

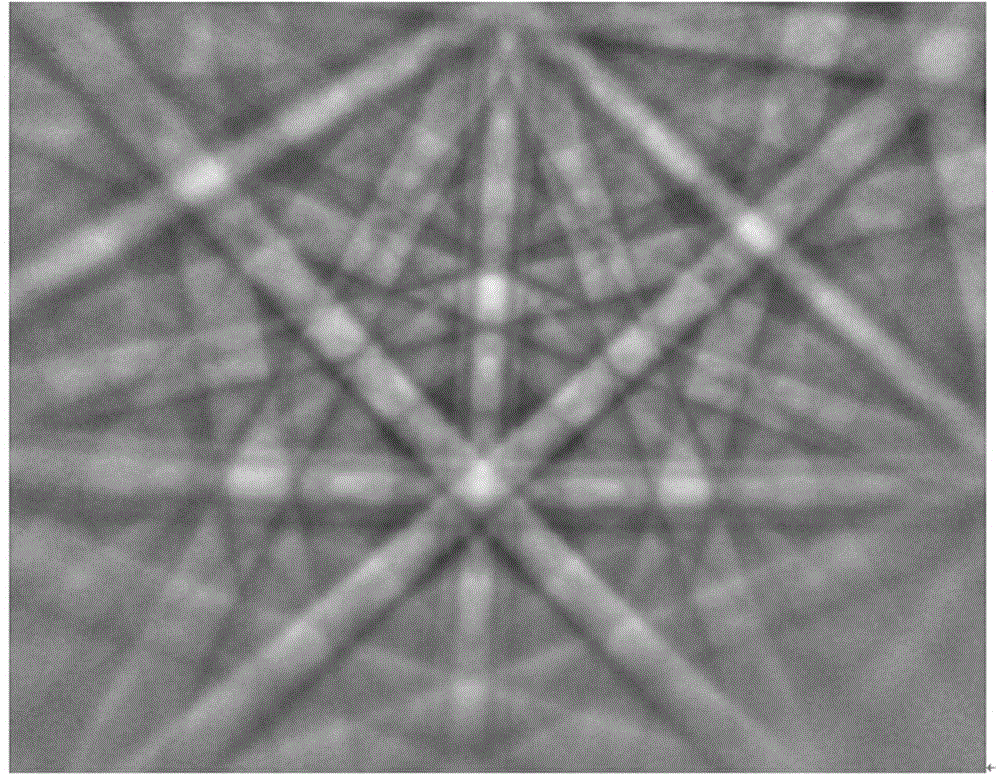

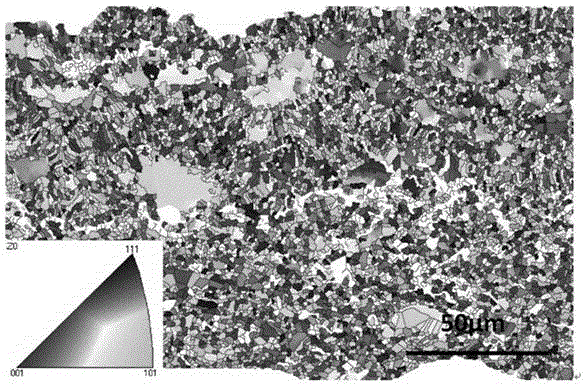

[0019] Embodiment 1: see figure 1 , figure 2 , image 3 , An electron backscatter diffraction (EBSD) sample 2 is placed on the sample stage 1 of the present invention, and an argon ion beam 3 bombards the electron backscatter diffraction (EBSD) sample 2 .

[0020] First, the electron backscatter diffraction (EBSD) sample of the zirconia thermal barrier coating was roughly ground, mechanically polished, rinsed with water, cleaned ultrasonically in anhydrous ethanol, and air-dried with a hair dryer; then, the zirconia was heated The electron backscatter diffraction (EBSD) sample of the barrier coating is fixed on the sample stage of the argon ion beam mill, and the horizontal position and vertical height of the electron backscatter diffraction (EBSD) sample of the zirconia thermal barrier coating are adjusted to ensure that When the electron backscatter diffraction (EBSD) sample of the zirconia thermal barrier coating is subjected to argon ion beam grinding, the argon ion bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com