Preparation and detection method of humidity sensor

A humidity sensor and carbon nanotube technology, applied in the direction of material resistance, can solve the problems of increasing the difficulty of material structure design and manufacturing, increasing the cost of manufacturing and maintenance, and the incompatibility of sensing elements and materials, so as to achieve good recovery Good compatibility, good compatibility, good effect on humidity sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The anionic surfactant used in the following examples is sodium dodecylbenzenesulfonate (SDBS); carbon nanotubes are carbon nanotubes with carboxyl groups (-COOH) after surface treatment, purchased from the Chinese Academy of Sciences Chengdu Organic Chemical Co., Ltd., model TNMC3, its basic physical properties are shown in the table below:

[0019] Basic Physical Properties of MWNTs

[0020]

[0021]

[0022] The present invention will be further described below in conjunction with the example shown in accompanying drawing:

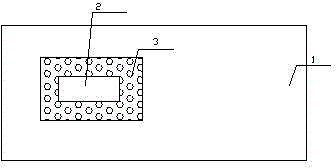

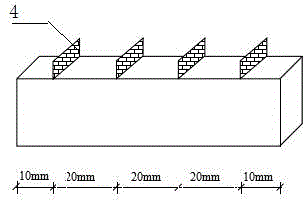

[0023] see figure 1 , 2 As shown, a new nanometer humidity sensor includes: a concrete shell 1, a built-in humidity sensor element 2, and a waterproof layer 3 arranged between the concrete shell 1 and the humidity sensor element 2.

[0024] The production process of the humidity sensor original 2 is as follows:

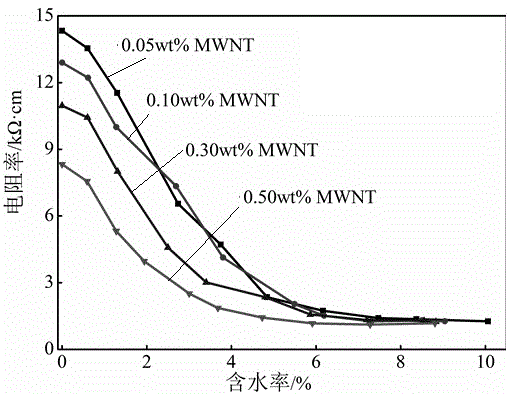

[0025] (1) Add anionic surfactant (SDBS) into water, ultrasonically disperse for 1-2min, ultrasonic power 100w, add carbon na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com