Method of producing silicon-on-insulator article

A technology of silicon-on-insulator and products, applied in the field of manufacturing of silicon-on-insulator products or products, SOI products or products, can solve problems such as poor thermal conductivity and shorten the service life of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

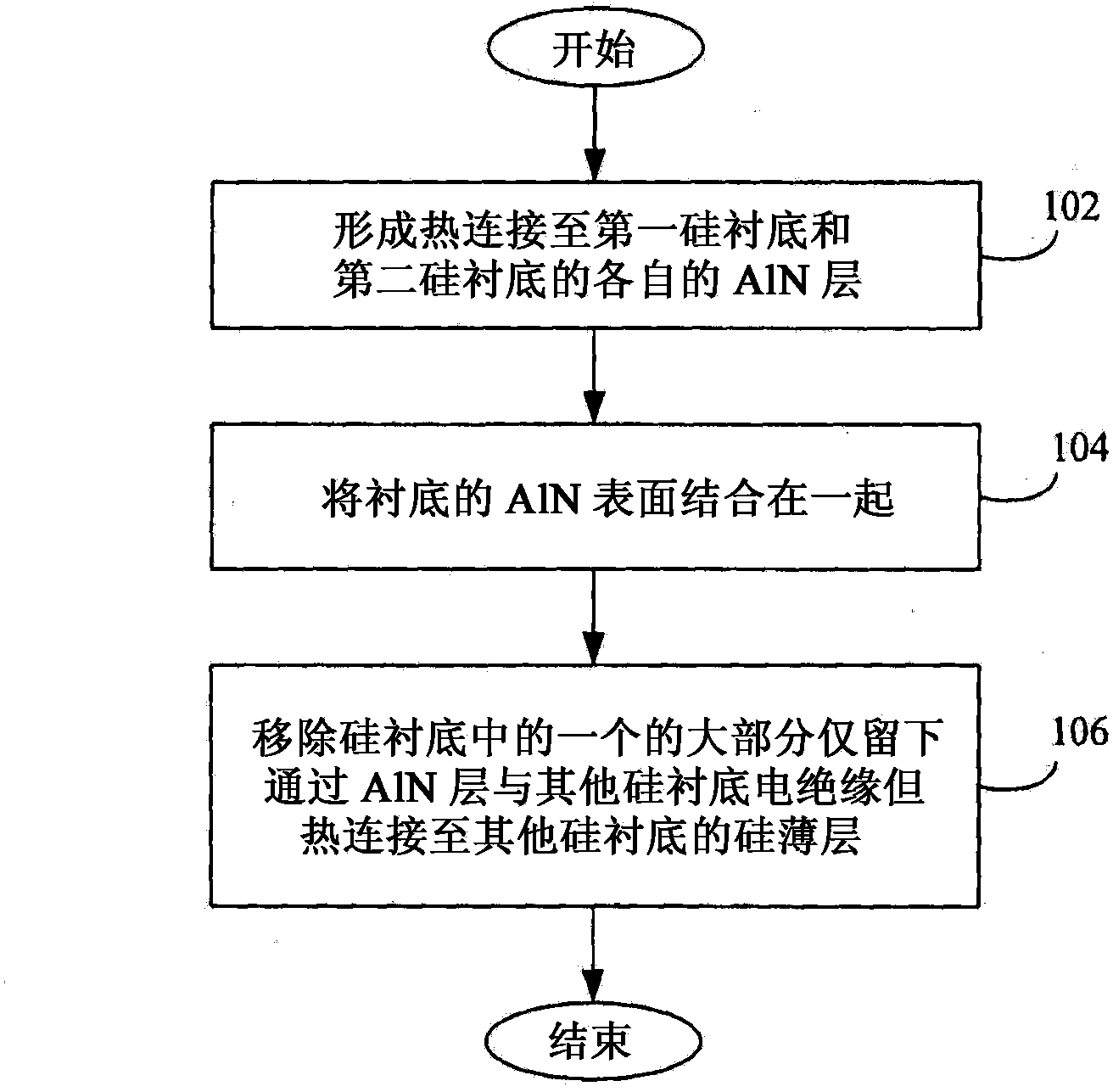

Method used

Image

Examples

Embodiment

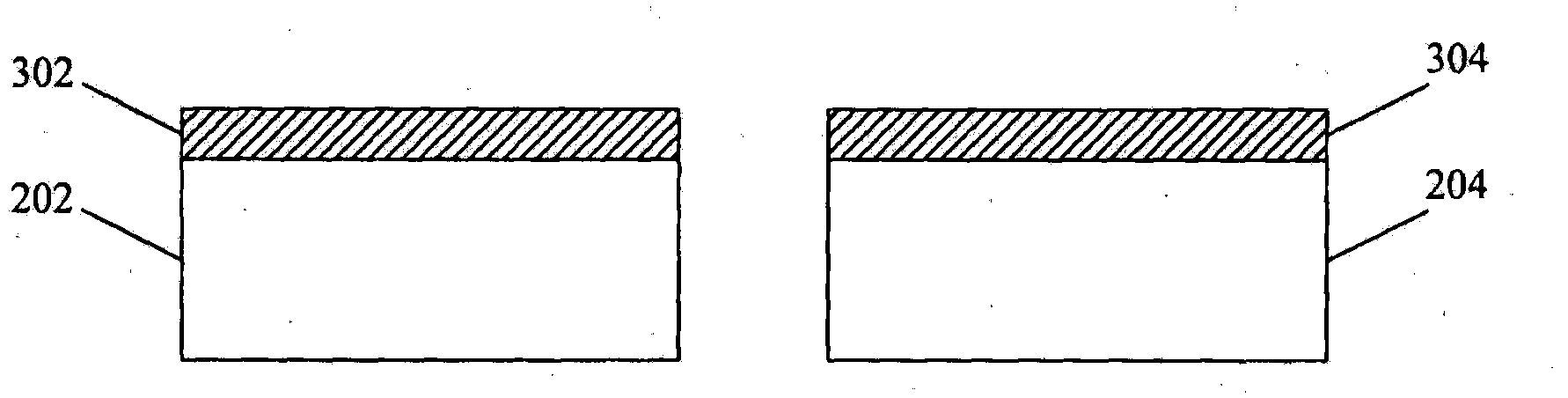

[0067] A 200 nm thick AlN layer 702, 704 was deposited simultaneously on the clean silicon surfaces of the two silicon wafers 706, 708 by reactive sputtering (RS) at a temperature of about 300°C. Wafers 706, 708 are 600 [mu]m thick, bulk single crystal wafers with 100 Ohm-cm. Both wafers 706, 708 have a (100) crystallographic orientation. Both AlN layers 702, 704 are grown with nitrogen-rich surfaces to reduce oxidation, thereby increasing the bonding strength between the two AlN layers 702, 704.

[0068] Such as Figure 7 As shown, (only) a silicon wafer 708 is then ion implanted using hydrogen ions 710 through the AlN layer 704 to 6×10 at 150 keV 16 cm -2 energy density or magnetic recording density. This forms a buried hydrogen layer 712 at a depth 714 of about 1.21±0.01 μm below the wafer surface, ie, about 1.0 μm below the AlN:Si interface.

[0069] Such as Figure 8 As shown, AlN layers 702, 704 were then face-to-face bonded using a Karl Suss SB6VAC wafer bonder at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com