Tissue-engineered bone based on entochondrostosis system and construction method thereof

A technology of endochondral osteogenesis and tissue engineering bone, applied in prosthesis, medical science and other directions, can solve the problems of repair failure, ischemic necrosis of core parts, etc., and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

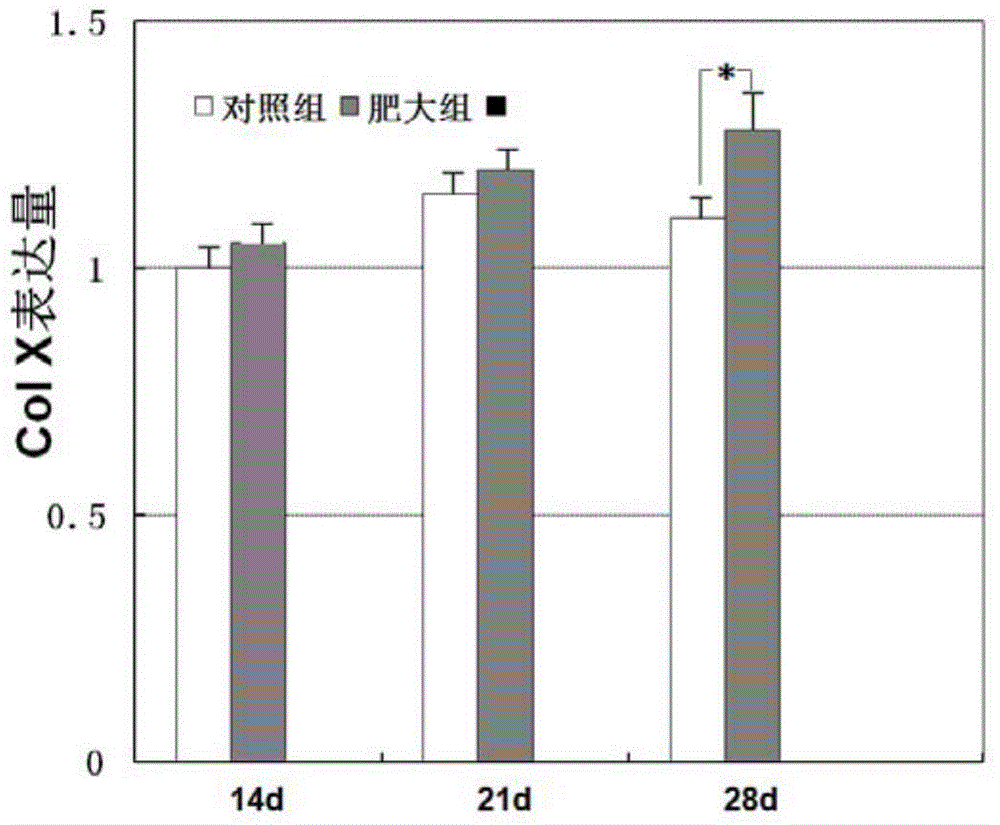

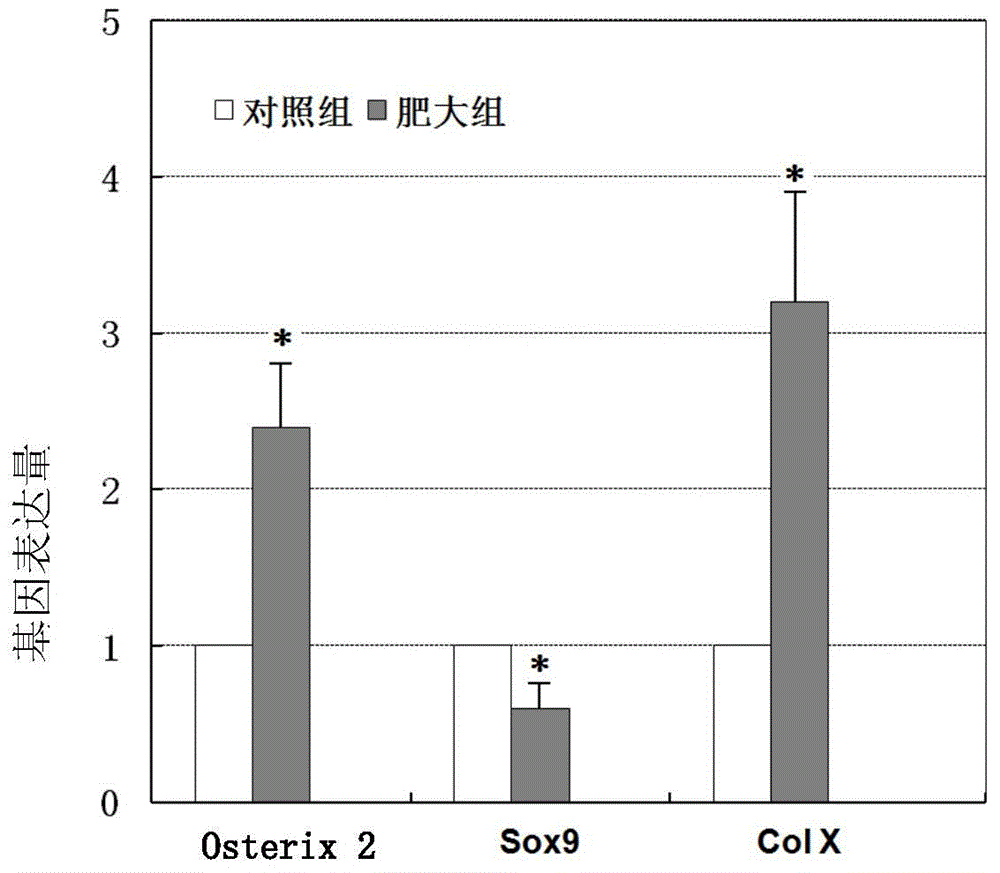

[0022] Example 1. Construction of tissue engineered bone based on endochondral osteogenesis system

[0023] 1. Culture of bone marrow MSCs

[0024] Use a heparin-treated syringe to extract 2-3 mL of human bone marrow under sterile conditions, immediately add it to a centrifuge tube filled with an equal amount of DMEM low-sugar medium, and quickly and gently blow it to make a cell suspension. Gently add to the centrifuge tube with an equal volume of lymphocyte separation medium, centrifuge at 2000r / min for 20min, collect the mononuclear cells in the buffy coat layer in another centrifuge tube, wash with DMEM (centrifuge at 1000r / min for 5min) twice, The supernatant was discarded, and the cells were resuspended in DMEM-L complete medium containing 15% fetal bovine serum, and diluted with 1×10 6 / mL cell density inoculated in a culture flask, recorded as the primary generation, placed at 37°C, 5% CO 2 Culture in a constant temperature incubator, change the medium every 3 days, ...

Embodiment 2

[0034] Example 2. In vivo ectopic osteogenesis of tissue engineered bone based on endochondral osteogenesis system

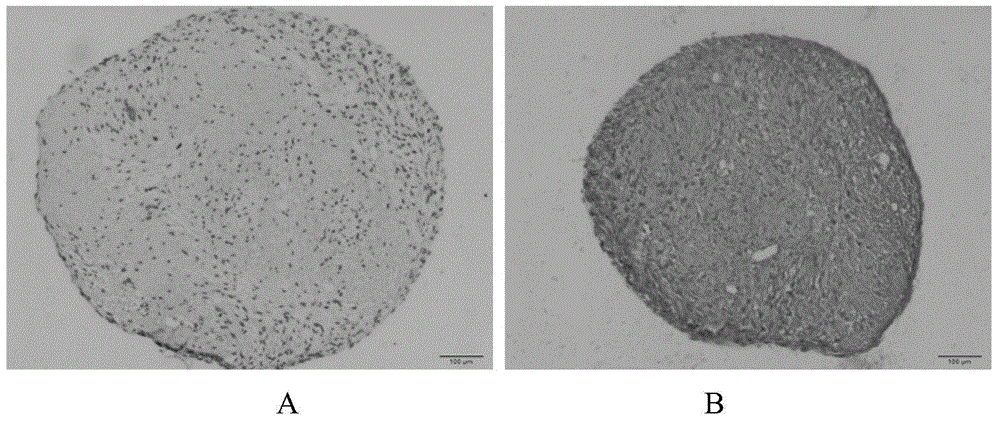

[0035] The tissue engineered bone based on the endochondral osteogenesis system constructed in Example 1 (hypertrophy group and control group) was implanted subcutaneously in nude mice, and after feeding for 8 weeks, the subcutaneous bone pieces were taken out and stained with Safranin O to observe subcutaneous heterotopia in nude mice bone formation, results such as Figure 4 shown.

[0036] The results showed that after 8 weeks of in vivo culture in the hypertrophy group, bone tissue specimens were ectopically formed under the skin of the nude mice. Gross observation: wrapped in a film, translucent white, with a certain degree of toughness when touched. Histological observation: there are a small amount of fibrous cells and fibrous tissue wrapped around, lymphocytes can be seen but not immersed into the deep layer, there is a small amount of cartilage-like t...

Embodiment 3

[0037] Example 3. Repair of bone defect with tissue engineered bone based on endochondral osteogenesis system

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com