Fabrication method of microneedle array based on high voltage electric field

A technology of microneedle array and manufacturing method, which is applied in the direction of pharmaceutical devices and other medical devices, can solve the problems of unclear biocompatibility, complicated processing process, high cost, etc., and achieve simple and easy-to-operate manufacturing methods, and realize direct The effect of transmission and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

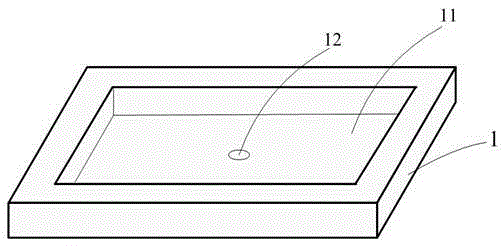

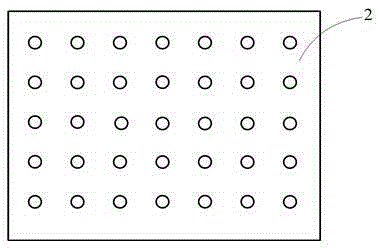

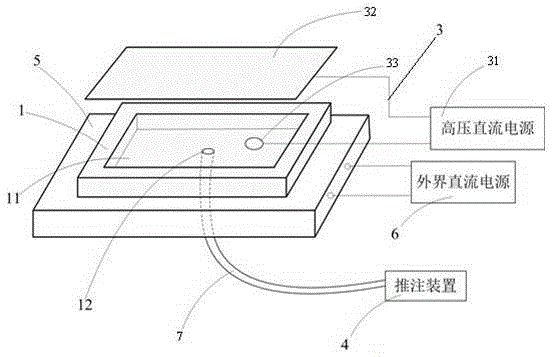

[0032] like Figure 1 to Figure 4 Shown is the first embodiment of the manufacturing method of the microneedle array based on the high-voltage electric field of the present invention, as Figure 4 As shown, the fabrication equipment based on the microneedle array includes a base mold 1, a hole mold 2 with several small holes, an electric field generating device 3 for generating a high-voltage electric field, and a bolus injector for injecting the base mixture solution into the base mold 1. Device 4, the injection device 4 is connected with the base mold 1, and the method for making the microneedle array includes the following steps:

[0033] a. making base mixture solution, said base mixture solution is mixed by epoxy resin, epoxy resin curing agent, the medicine that needs to be injected, and the base mixture solution that has been mixed uniformly is contained in the injection device 4;

[0034] b. The hole mold 2 is placed on the upper surface of the base mold 1, and the in...

Embodiment 2

[0052] like Figure 5 Shown is the second embodiment of the manufacturing method of the microneedle array based on the high-voltage electric field of the present invention. This embodiment is similar to Embodiment 1, the difference is that in this embodiment, a small hole with an aperture of 0.5 mm is selected, and the hole The distance is 30mm, and 35 small holes are evenly distributed on the hole die 2, 7 on the long side and 5 on the short side. In this embodiment, no heating source is added to the base mold 1, and the microneedle array structure is directly air-dried and solidified, which can save costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com