Straw mixture artificial board and processing method

A processing method and technology of mixing materials, which are applied in the direction of manufacturing tools, wood processing appliances, and pretreatment of molding materials, etc., can solve the problems of low nail holding force, low mechanical strength of medium density boards, and low lignin content, etc., and achieve improvement Integrity, improved quality and strength, good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

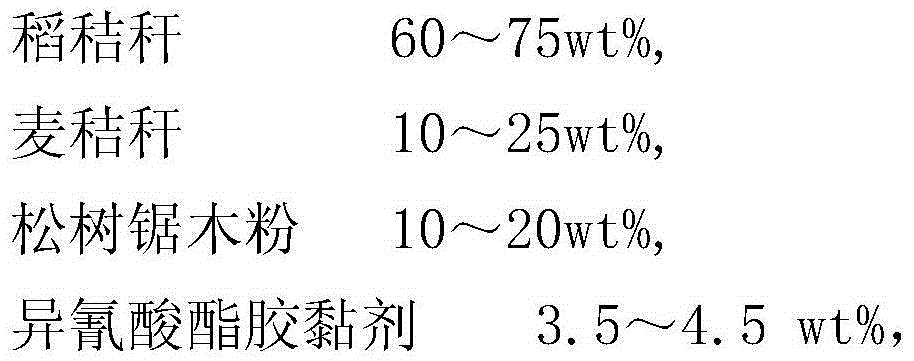

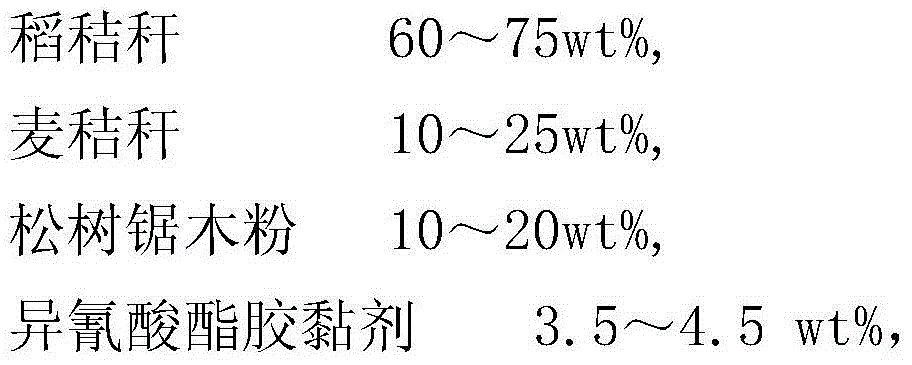

Embodiment 1

[0053] This embodiment provides a straw mixture wood-based panel, which is made of the following raw materials: rice straw 65-75wt%, wheat straw 15-25wt%, pine sawdust 10-20wt%, Calculate the weight percentage of each of the above components under the same water content. In the examples of the present invention, wt% means the weight percentage of the component. Among them, the respective proportions of rice straw, wheat straw and pine sawdust can be selected according to specific needs within the above-mentioned range, and the total can be equal to 100%. Since the fiber length and width of pine sawn powder are larger than those of rice straw and wheat straw, and its mechanical strength is also greater, it is possible to choose to add more or less pine sawn powder according to the purpose of the board. Preferably, the sawn powder of pine tree can be sawed powder of masson pine or sawed powder of larch or sawed powder of red pine or sawed powder of foreign pine.

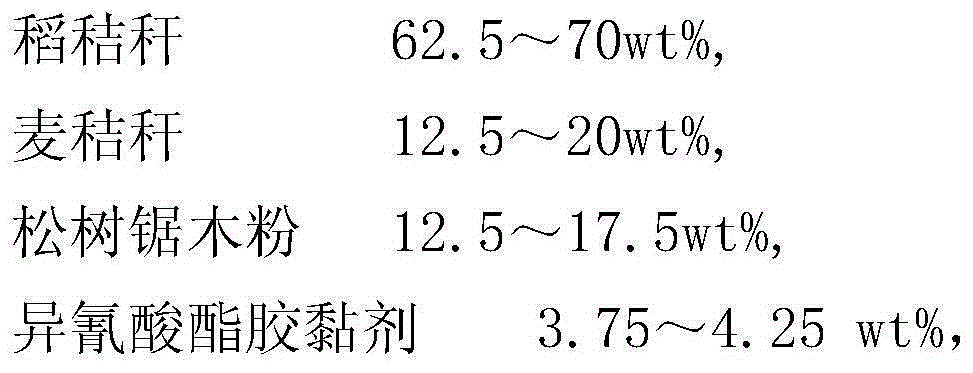

Embodiment 2

[0055]This embodiment provides a straw mixture wood-based panel, which is made of the following raw materials: rice straw 67.5-70wt%, wheat straw 17.5-20wt%, pine sawdust 12.5-17.5wt% , in the case of the same water content to calculate the weight percentage of the above components. Preferably, the sawn powder of pine tree can be sawed powder of masson pine or sawed powder of larch or sawed powder of red pine or sawed powder of foreign pine.

Embodiment 3

[0057] This embodiment provides a straw mixture wood-based panel, which is made of the raw materials of the following components: rice straw 68.5wt%, wheat straw 18.5wt%, pine sawdust 13wt%, at the same water content In the case of calculating the weight percentage of each of the above components. Wherein, the pine sawn powder is red pine sawn powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com