Thermoplastic honeycomb board and preparation method thereof

A thermoplastic, honeycomb technology, used in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve problems such as uneven placement, low connection strength, and broken honeycomb substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

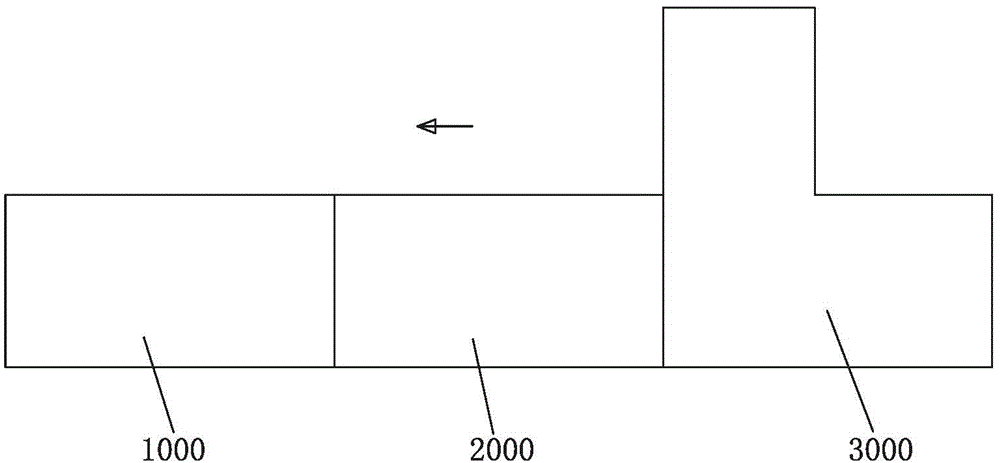

[0063] A preparation method for a thermoplastic honeycomb plate, comprising the steps of:

[0064] 1) manufacturing a double-layer composite pipe, the inner layer of the double-layer composite pipe is a high melting point material layer, the outer layer of the double layer composite pipe is a low melting point material layer, and the melting point of the low melting point material layer is lower than the melting point of the high melting point material layer;

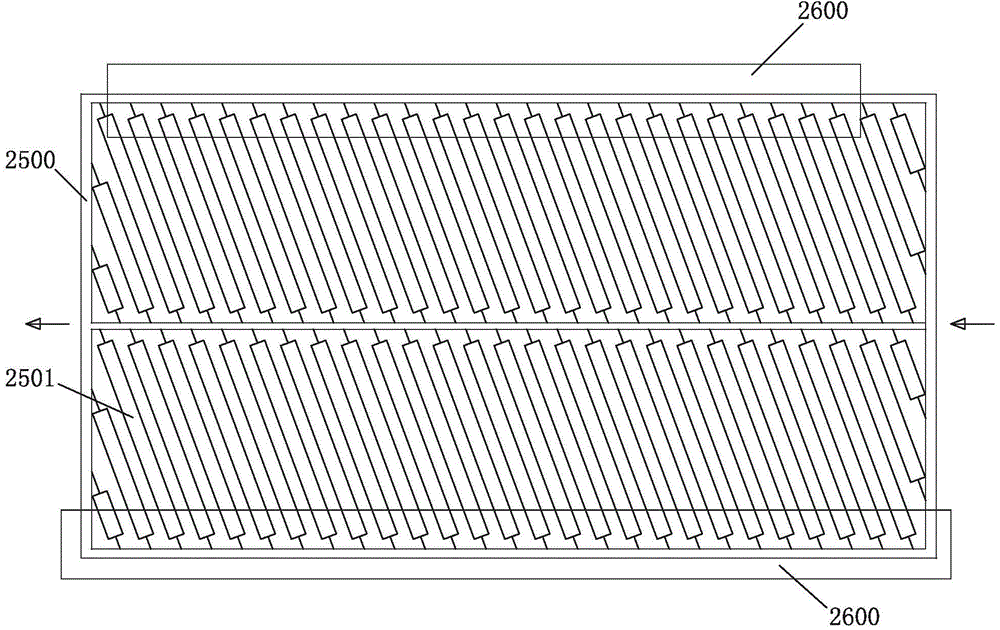

[0065] 2) A plurality of double-layer composite pipes are arranged in an orderly bundle, and the outer layer of the double-layer composite pipe is melted by heating while the inner layer is not melted. After cooling, the outer layers of the adjacent double-layer composite pipes are bonded together to form Honeycomb body;

[0066] 3) cutting the honeycomb body along the cross-section of the double-layer composite pipe to obtain a plate-shaped honeycomb substrate;

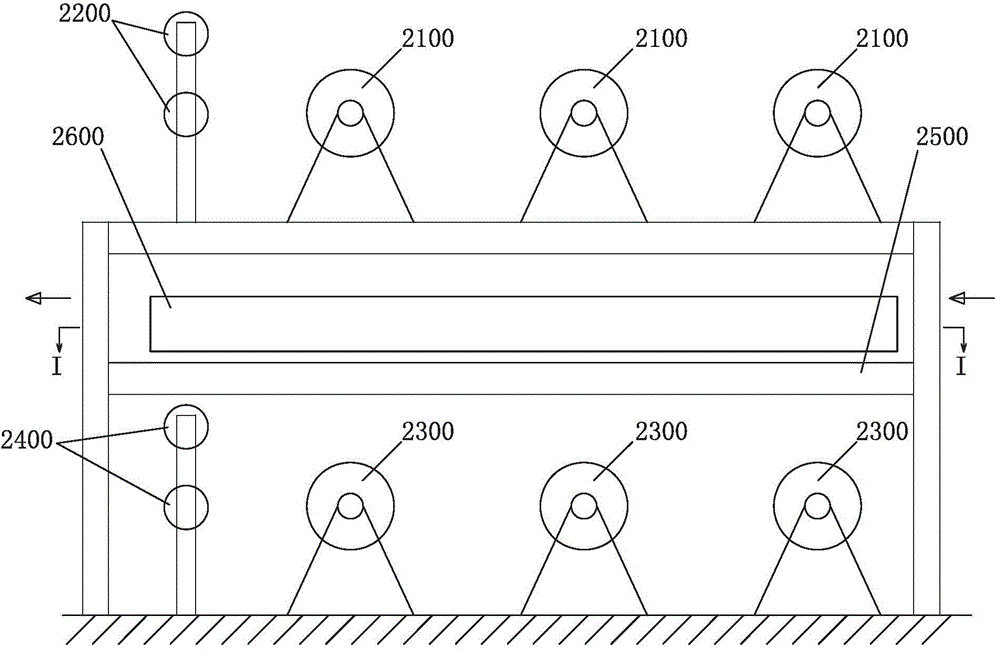

[0067] 4) The honeycomb base material is sent into a do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com