Concrete hydration heat inhibition material

A hydration heat suppression and concrete technology, which is applied in the field of building material concrete admixtures, can solve the problems of hydration heat suppression performance, economical and environmental protection to be improved, etc., so as to optimize the cement hydration process, improve durability, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 10wt% starch and 0.01wt% high temperature-resistant α-amylase with water, heat in a water bath to 90°C, react for 0.2 hours, cool, add hydrochloric acid to adjust pH = 1 to inactivate α-amylase, and then use alkali Neutralize until the pH is neutral, dry and pulverize to obtain dextrin powder, and the DE value of the prepared dextrin is 6.

[0030] Mix 10wt% dextrin and 1wt% sodium hydroxide with water, add 0.5wt% propylene oxide dropwise at a constant speed at 0°C, put it in a constant temperature water bath at 30°C, react for 12h, and neutralize with hydrochloric acid to neutral , after spray drying, 95% ethanol was dissolved and filtered to remove inorganic salts, and the filtrate was dried to obtain a modified heat of hydration inhibiting material.

[0031] Add the prepared hydration heat inhibiting material into the concrete mixing process (the amount is 0.5wt% of the cement amount), and the concrete mix ratio is as follows: 162kg of water, 360kg of cement ("Ji...

Embodiment 2-12

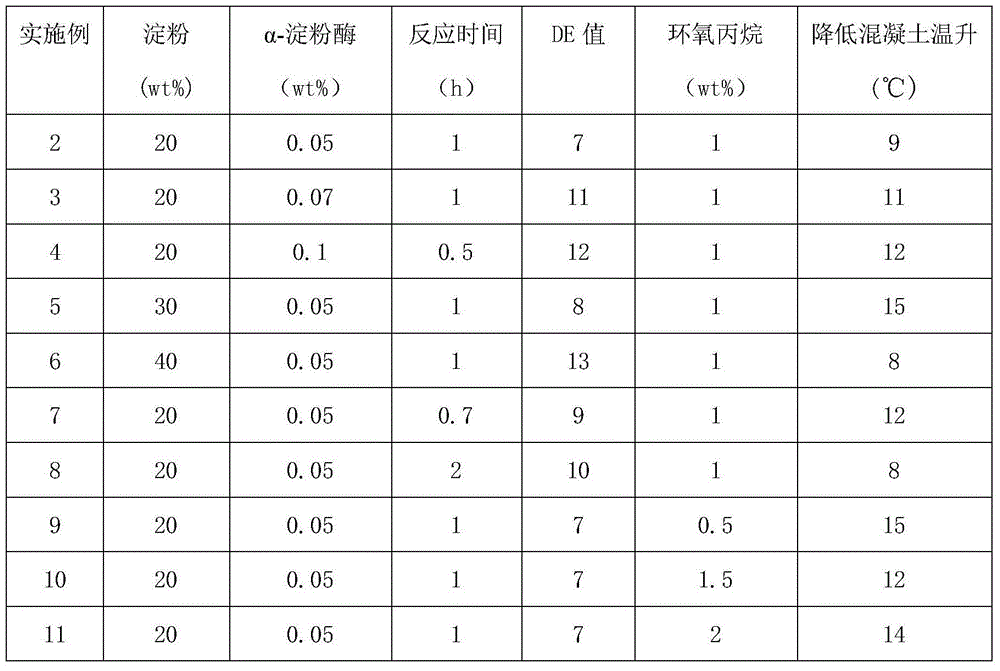

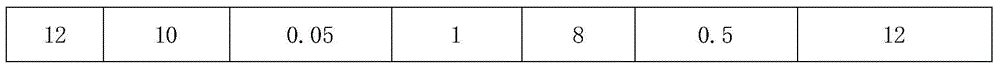

[0033] See Table 1.

[0034] Table 1 Example 2-12

[0035]

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com