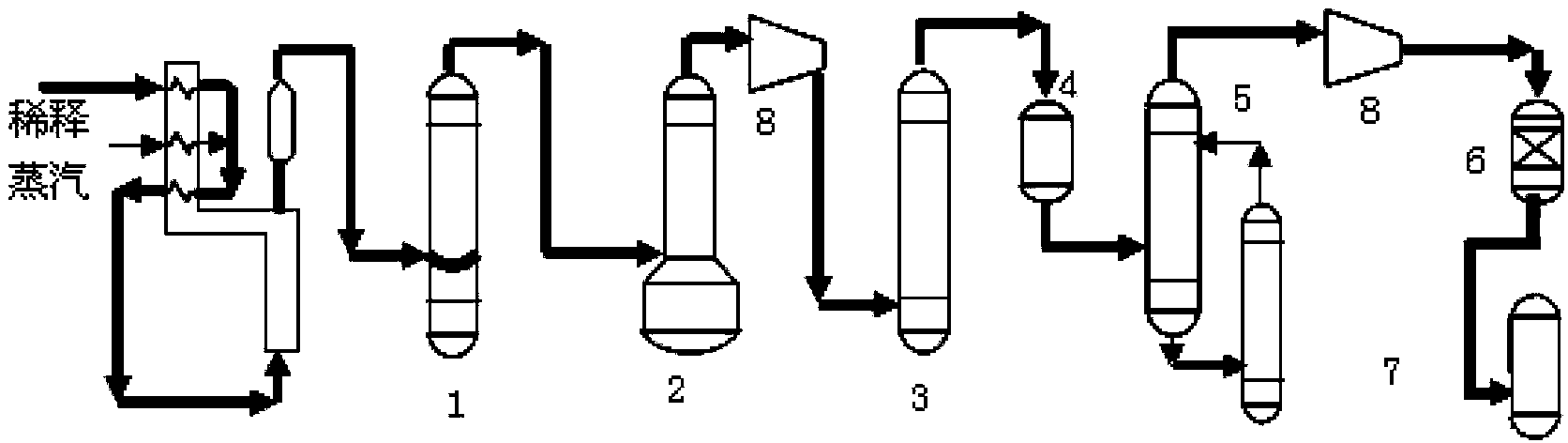

C2 fraction selective-hydrogenation method

A selective hydrogenation and fractionation technology, applied in hydrocarbons, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve problems such as low selectivity, runaway temperature, and prone to runaway temperature in the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0063] Embodiment 1~3 catalyst preparation

Embodiment 1

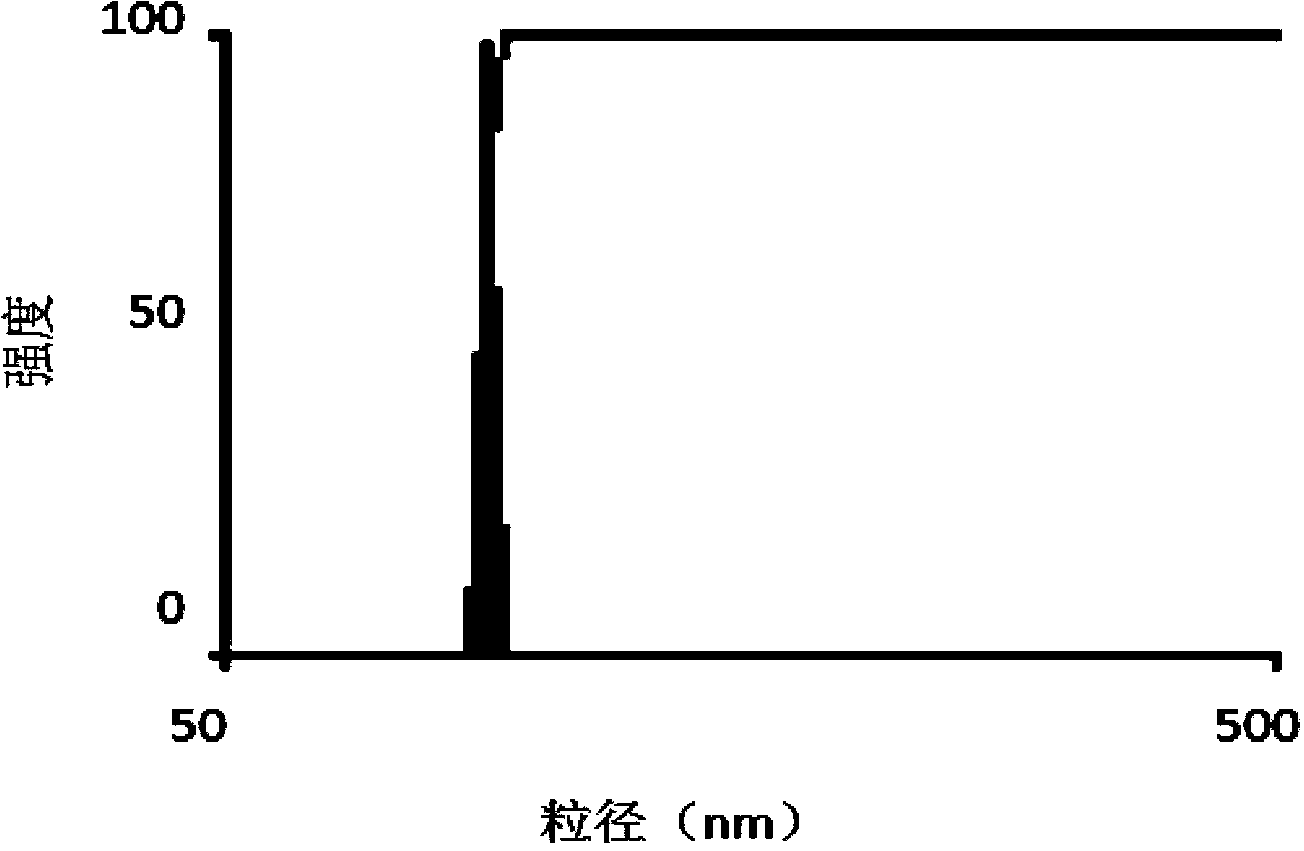

[0064] Example 1 carrier

[0065] A commercially available bimodal pore distribution cylindrical alumina carrier with a diameter of 5 mm and a length of 5 mm was used. After calcination at 1300°C for 4 hours, the bimodal peaks of pore diameters are at 45nm and 200nm respectively, the pore volume is 0.15ml / g, and the specific surface area is 10m 2 / g.

Embodiment 2

[0066] Example 2 Carrier

[0067] A commercially available bimodal pore distribution spherical alumina carrier with a diameter of 5 mm was used. After calcination at 1200°C for 4 hours, the bimodal peaks of pore diameters are at 30nm and 150nm respectively, the pore volume is 0.2ml / g, and the specific surface area is 15m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com