Device and method for continuous production of propionic acid peroxide

A technology of peroxypropionic acid and production device, applied in the field of peroxypropionic acid continuous production device, can solve the problems of difficulty in production control, poor material discharge, hydrogen peroxide inflow, etc., and achieves increased extraction speed and convenient control. , The effect of simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

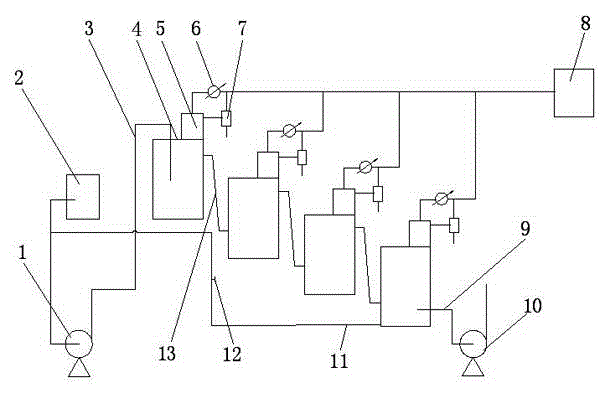

[0032] Below in conjunction with embodiment and accompanying drawing, the present invention will be described in further detail:

[0033] see figure 1 , the embodiment of a kind of continuous production device of peroxypropionic acid of the present invention, comprises raw material tank 1, feed pump 2, conveying pipeline 3, several reaction kettles 4 and vacuum system 8 connected in series, by feed pump 2, The reaction kettle 4 directly connected to the reaction tank 1 by the delivery pipeline 3 is called the first-stage reaction kettle 4 , and each reaction kettle 4 is provided with a feed inlet and a discharge outlet. The raw material tank 1 is placed at the same platform height as the first-stage reactor 4, and the feed ports of the remaining reactors 4 are respectively connected to the discharge ports of the upper-stage reactor 4 through respective overflow pipes 13 .

[0034] The concrete structure of embodiment is:

[0035] The above-mentioned reactors are generally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com