Liquid Crystal Alignment Agent, Liquid Crystal Alignment Film, And Liquid Crystal Display Element And Method Of Manufacturing The Same

A liquid crystal alignment agent and a technology for liquid crystal alignment, applied in the directions of liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of inability to obtain a uniform and good liquid crystal alignment film, uneven film spread of the alignment agent, and poor solubility, and achieve excellent Effect of display quality, improved coatability, good pretilt angle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1 and

[0078] Synthesis Example 1 and Synthesis Example 2

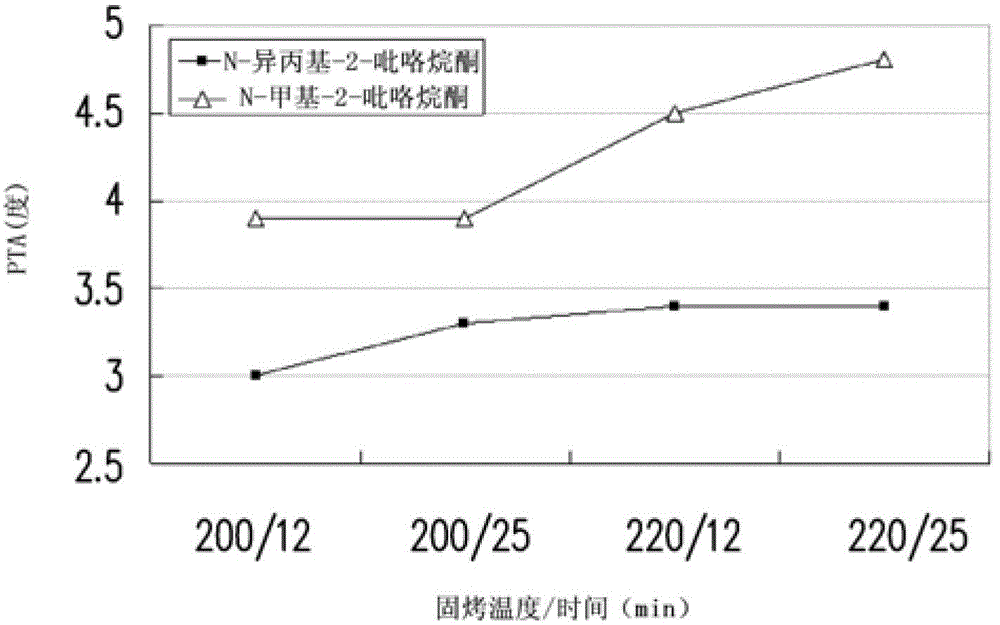

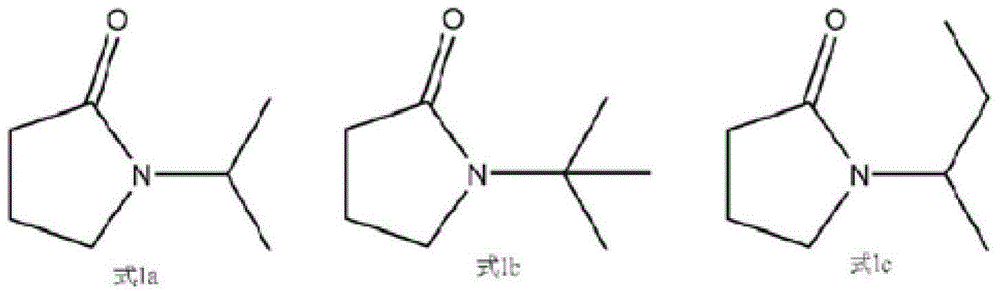

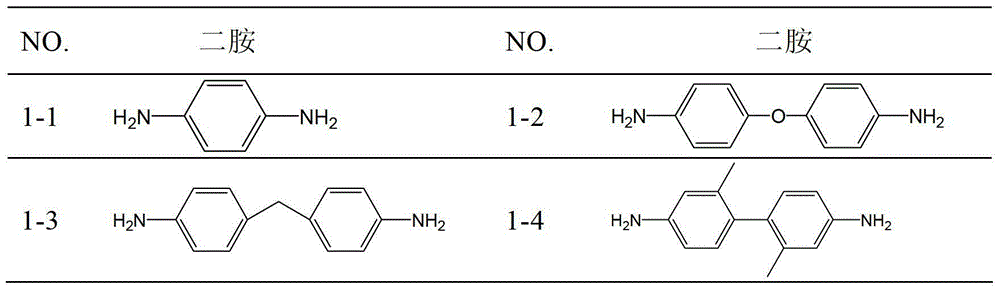

[0079] Add diamine and tetracarboxylic dianhydride to N-methyl-2-pyrrolidone in sequence (its chemical structure and weight are shown in Table 1 and Table 3) to prepare a solution with a solid content of 20% by weight, and in React at 40°C to 60°C for 4 hours to 6 hours to obtain a polyamic acid polymer, and then purify it with a solvent (such as methanol or water) with poor solubility for the polyamic acid polymer, and by reducing Drying under pressure gave Polymer A1 and Polymer A2.

Synthetic example 3 and

[0080] Synthesis Example 3 and Synthesis Example 4

[0081] Add diamine and tetracarboxylic dianhydride to N-isopropyl-2-pyrrolidone in sequence (its chemical structure and weight are shown in Table 1 and Table 3) to prepare a solution with a solid content of 20% by weight, and React at 40°C to 60°C for 4 hours to 6 hours to obtain a polyamic acid polymer, and then purify it with a solvent (such as methanol or water) that has poor solubility for the polyamic acid polymer, and by reducing Drying under pressure gave Polymer A3 and Polymer A4.

Synthetic example 5

[0083] Sequentially add diamine and tetracarboxylic dianhydride to N-methyl-2-pyrrolidone (as shown in Table 3) to prepare a solution with a solid content of 20% by weight, and store at 40°C to 60°C React for 4 hours to 6 hours to obtain a polyamic acid polymer, then add pyridine and acetic anhydride to the obtained polyamic acid polymer (the amount depends on the polyimidization ratio), at 100°C to 110°C The dehydration / ring-closing reaction was carried out at C for 3 hours to 4 hours, and the resulting solution was precipitated with methanol, purified with methanol, and finally collected and dried under reduced pressure to obtain polymer B1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com