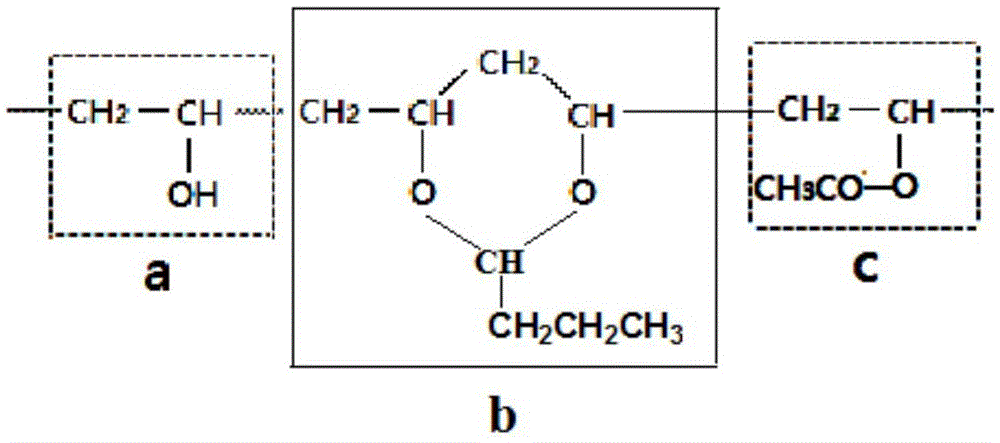

Continuous preparation method of polyvinyl butyral resin

A technology of polyvinyl butyral resin and polyvinyl alcohol, which is applied in the field of preparation of polymer compounds, can solve the problems of insufficient mixing of raw materials, unstable product batches, uneven particles, etc., and achieves batch stability and prevention. The effect of particle agglomeration and agglomeration, particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

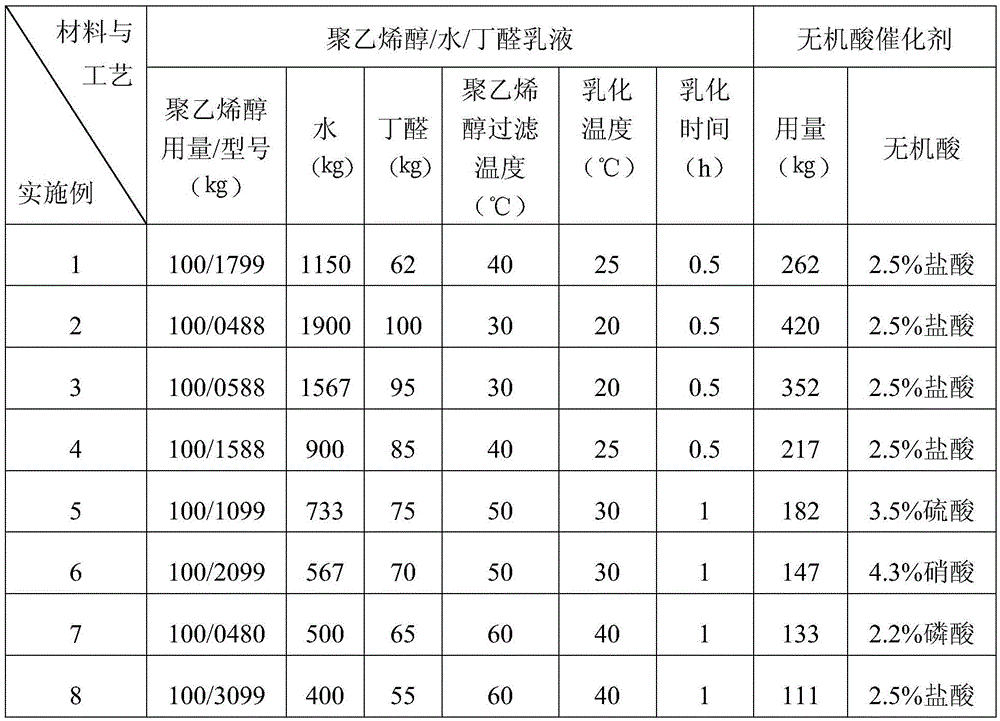

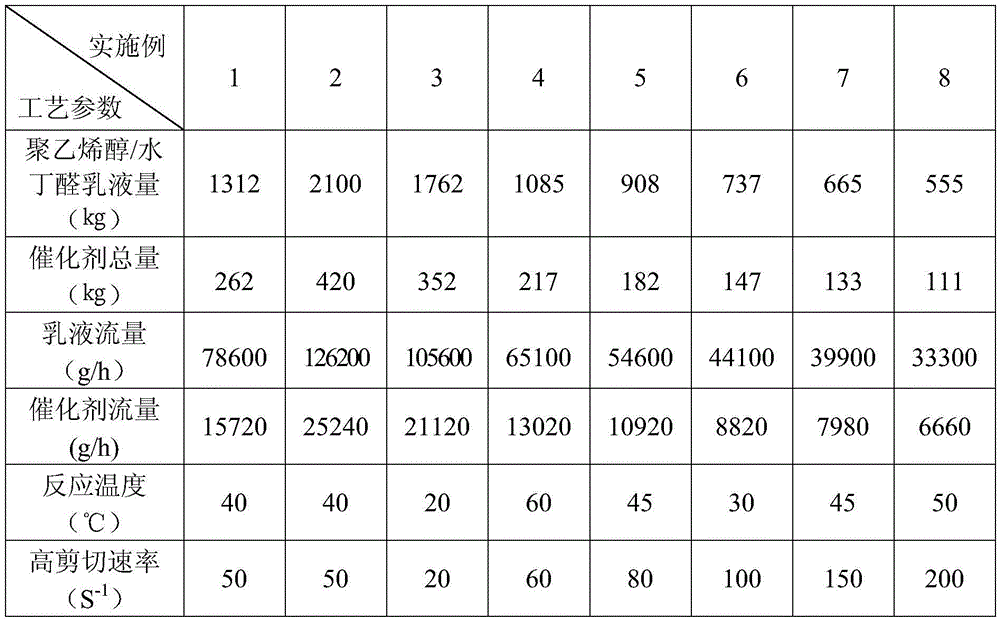

Embodiment 1~8

[0038] The basic reaction synthesis process of the continuous preparation method of a kind of polyvinyl butyral resin of embodiment 1~8:

[0039] 1. Preparation of polyvinyl alcohol / water / butyraldehyde emulsion:

[0040] Add 100 parts by mass of polyvinyl alcohol and 400-1900 parts by mass of water into the dissolution kettle, stir and heat to 95°C ± 2°C, keep warm for 2 hours to completely dissolve the polyvinyl alcohol, cool down to 30°C-60°C and filter to obtain 500 ~2000 parts by mass of polyvinyl alcohol / water solution, and then put the obtained polyvinyl alcohol / water solution and 55~100 parts by mass of butyraldehyde that has been filtered into the emulsifier, and stir at 20°C~60°C for 0.5h~1.5h 555-2100 parts by mass of polyvinyl alcohol / water / butyraldehyde emulsion are prepared.

[0041] 2. Preparation of polyvinyl butyral resin:

[0042] 555-2100 parts by mass of polyvinyl alcohol / water / butyraldehyde emulsion and 111-420 parts by mass of inorganic acid catalyst obt...

Embodiment 9

[0053] A kind of continuous preparation method of polyvinyl butyral resin, the steps are:

[0054] a. Preparation of polyvinyl alcohol / water / butyraldehyde emulsion:

[0055] Add 100 parts by mass of polyvinyl alcohol and 1150 parts by mass of water into the dissolution kettle, stir and heat to 95°C ± 2°C, keep warm for 2 hours to completely dissolve the polyvinyl alcohol, cool down to 45°C and filter to obtain 1250 parts by mass of polyethylene Alcohol / water solution, and then the obtained polyvinyl alcohol / water solution and (filtered) 77.5 parts by mass of butyraldehyde were mixed and stirred by an emulsifier at 20°C to 60°C for 0.75h to obtain 1327.5 parts by mass of polyvinyl alcohol / water / butyraldehyde emulsion;

[0056] The polyvinyl alcohol is polyvinyl alcohol with a degree of alcoholysis of 80% to 99% and a degree of polymerization of 400 to 3000;

[0057] Described water can be pure water, distilled water or deionized water;

[0058] The emulsifier is a high-spe...

Embodiment 10

[0064] A kind of continuous preparation method of polyvinyl butyral resin, the steps are:

[0065] a. Preparation of polyvinyl alcohol / water / butyraldehyde emulsion:

[0066] Add 100 parts by mass of polyvinyl alcohol and 400 parts by mass of water into the dissolution kettle, stir and heat to 95°C ± 2°C, keep warm for 2 hours to completely dissolve the polyvinyl alcohol, cool down to 30°C and filter to obtain 500 parts by mass of polyethylene Alcohol / water solution, and then the obtained polyvinyl alcohol / water solution and (filtered) 55 parts by mass of butyraldehyde were mixed and stirred by an emulsifier at 20°C for 1 hour to obtain 555 parts by mass of polyvinyl alcohol / water / butyraldehyde emulsion ;

[0067] The polyvinyl alcohol is polyvinyl alcohol with a degree of alcoholysis of 80% to 99% and a degree of polymerization of 400 to 3000;

[0068] Described water can be pure water, distilled water or deionized water;

[0069] The emulsifier is a high-speed dispersion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com