Robust regression modeling based dried slice flue gas ammonia prediction method

A robust regression and flue gas technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of high cost, labor and time, and achieve the effect of ensuring robustness, reducing detection costs, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

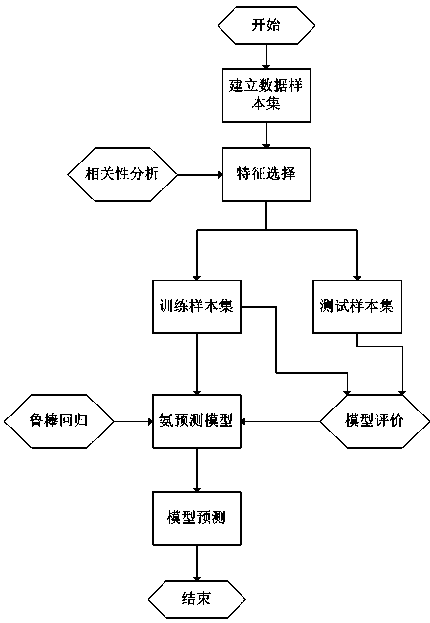

Method used

Image

Examples

Embodiment 1

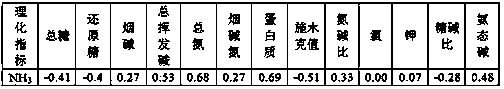

[0050] (1) Compare the physical and chemical data of the known baked sheet with the flue gas NH 3 The data is listed correspondingly, and a data sample set is established, in which the physical and chemical data include total sugar, reducing sugar, nicotine, total volatile alkali, total nitrogen, nicotine nitrogen, protein, Schmuck value, nitrogen-alkali ratio, chlorine, potassium, sugar Alkali ratio and ammonia base, as shown in the table below:

[0051]

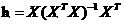

[0052] (2) Calculate the column vector x of each physical and chemical data in the data sample set obtained in step (1) 1 ~x n and flue gas NH 3 The column vector y of the data, the physical and chemical data and the flue gas NH are calculated respectively by the following formula 3 The linear correlation coefficient r:

[0053] (1)

[0054] In the formula: x is a column vector of some physical and chemical data, y is flue gas NH 3 The column vector of the data; get the physical and chem...

Embodiment 2

[0098] Same as steps (1) to (3) of Example 1, only replace other roasted slices to be tested, step (4) is as follows:

[0099] According to the characteristic index items selected in step (2), the corresponding physical and chemical data of the baked slices to be tested, that is, total sugar = 25.94, reducing sugar = 22.43, total volatile alkali = 0.28, total nitrogen = 1.9, protein = 9.43, Shimu Ke Value = 2.75, nitrogen-alkaline ratio = 0.84, and ammonia-alkali = 0.04 are applied as input variables to the prediction model in step (3), and the flue gas NH of the roasted sheet to be tested can be calculated and calculated. 3 The model predicted value Y=-30.08507-0.22834*total sugar+0.66854*reducing sugar+185.12201*total volatile base-77.63949*total nitrogen+13.16111*protein-0.26502*Shimuke value+11.63123*nitrogen-alkaline ratio-183.04849*ammonia State base=9.135. In order to verify the reliability of the model prediction results, the traditional detection method was used to m...

Embodiment 3

[0101] Same as steps (1) to (3) of Example 1, only replace other roasted slices to be tested, step (4) is as follows:

[0102]According to the characteristic index items selected in step (2), the corresponding physical and chemical data of the baked slices to be tested, that is, total sugar = 28.01, reducing sugar = 24.86, total volatile alkali = 0.29, total nitrogen = 1.8, protein = 8.66, Shimu Ke Value = 3.24, nitrogen-alkaline ratio = 0.75, and ammonia-alkali = 0.04 are applied as input variables to the prediction model in step (3), and the flue gas NH of the roasted sheet to be tested can be calculated and calculated. 3 The model predicted value Y=-30.08507-0.22834*total sugar+0.66854*reducing sugar+185.12201*total volatile base-77.63949*total nitrogen+13.16111*protein-0.26502*Shimuke value+11.63123*nitrogen-alkaline ratio-183.04849*ammonia State base=8,591. In order to verify the reliability of the model prediction results, the traditional detection method was used to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com