Preparation methods and application of porous carbon from towel gourd vegetable sponge and composite material of porous carbon

A composite material, porous carbon technology, applied in hybrid capacitor electrodes, structural parts, electrical components, etc., can solve the problems of difficult specific surface area, insufficient performance of supercapacitors and oxygen reduction catalysts, and achieve high specific surface area and good supercapacitor performance. and oxygen reduction catalytic performance, the effect of high adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Implementation Example 1: Preparation of porous carbon.

[0047] Put the chopped, washed loofah in the NH 3 Carry out carbonization treatment at 800°C in the atmosphere, the heating rate is 8°C / min, the holding time is 2h, NH 3 The flow rate is 60ml / min.

[0048] Mix the carbonized loofah and KOH at a mass ratio of 1:2, 2 Activated at 750°C for 1.5h. The product is washed with dilute hydrochloric acid and deionized water until the filtrate is neutral, and dried in a drying oven to obtain the porous carbon with a yield of about 11.5%.

Embodiment 2

[0049] Implementation Example 2: Preparation of porous carbon.

[0050] Put the chopped, washed loofah in the NH 3 Carry out carbonization treatment at 800°C in the atmosphere, the heating rate is 8°C / min, the holding time is 2h, NH 3 The flow rate is 60ml / min.

[0051] Mix the carbonized loofah and KOH at a mass ratio of 1:4, 2 Activated at 750°C for 1.5h. The product is washed with dilute hydrochloric acid and deionized water until the filtrate is neutral, and dried in a drying oven to obtain the porous carbon with a yield of about 8.3%.

Embodiment 3

[0052] Implementation Example 3: Preparation of Porous Carbon

[0053] Put the chopped, washed loofah in the NH 3 Carry out carbonization treatment at 900°C in the atmosphere, the heating rate is 8°C / min, the holding time is 2h, NH 3 The flow rate is 60ml / min.

[0054] Mix the carbonized loofah and KOH at a mass ratio of 1:2, 2 Activated at 750°C for 1.5h. The product is washed with dilute hydrochloric acid and deionized water until the filtrate is neutral, and dried in a drying oven to obtain the porous carbon with a yield of about 9.5%.

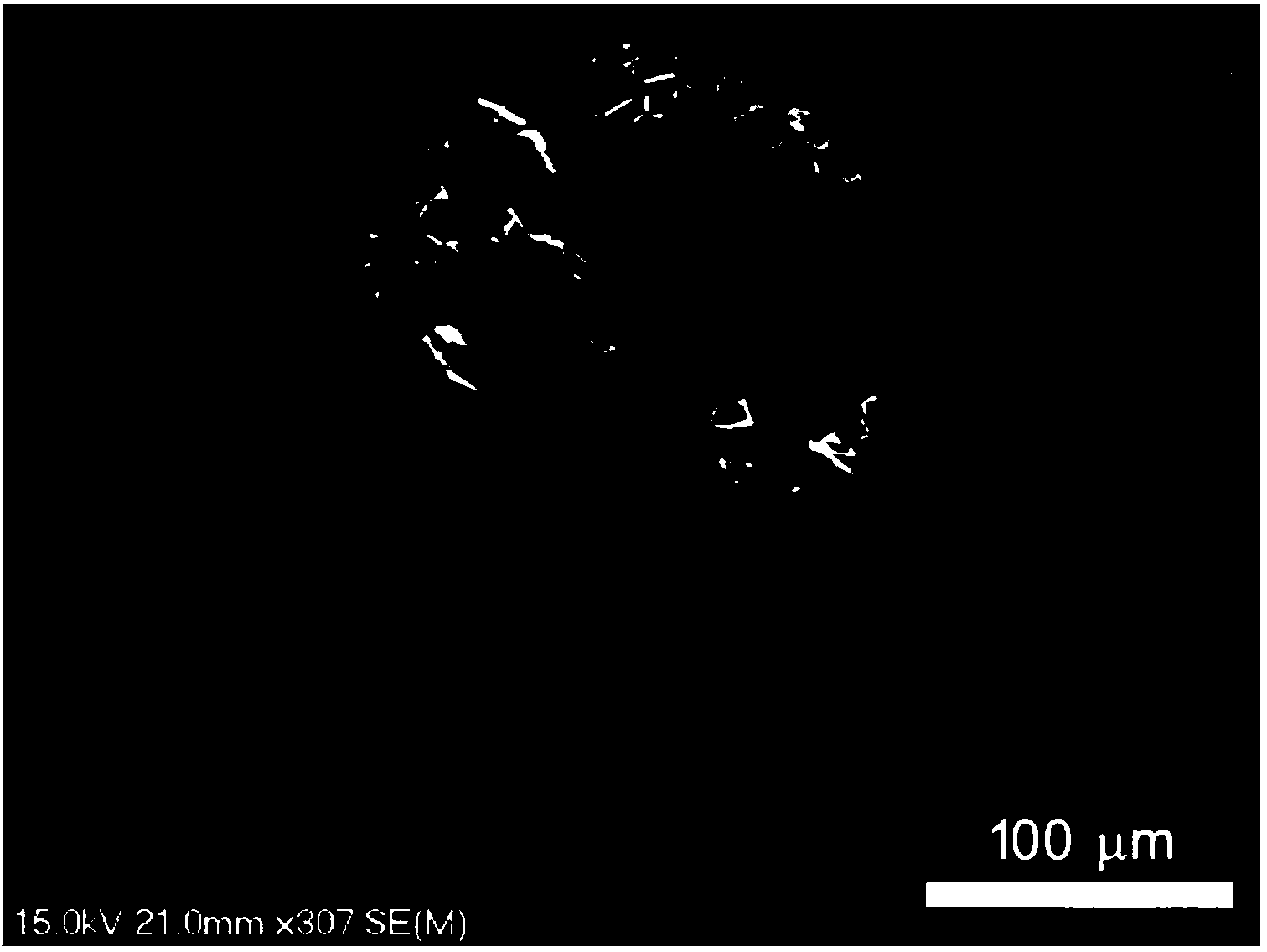

[0055] figure 1 is the SEM picture of the prepared porous carbon. It can be seen that the porous carbon prepared by the present invention is cylindrical, with a diameter of about 190 μm, and contains many parallel and densely arranged channels in the inside of the fiber, forming a cellular structure of a honeycomb. The opening of the channels is polygonal. Its diameter is about 1-15 μm, and the thickness of the hole wall is between 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com